High-energy electronic igniter circuit

A high-energy electronics and igniter technology, applied in the electrical field, can solve the problem of easy burning of resistance and achieve the effects of not easy to burn out, low cost, and low resistance consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

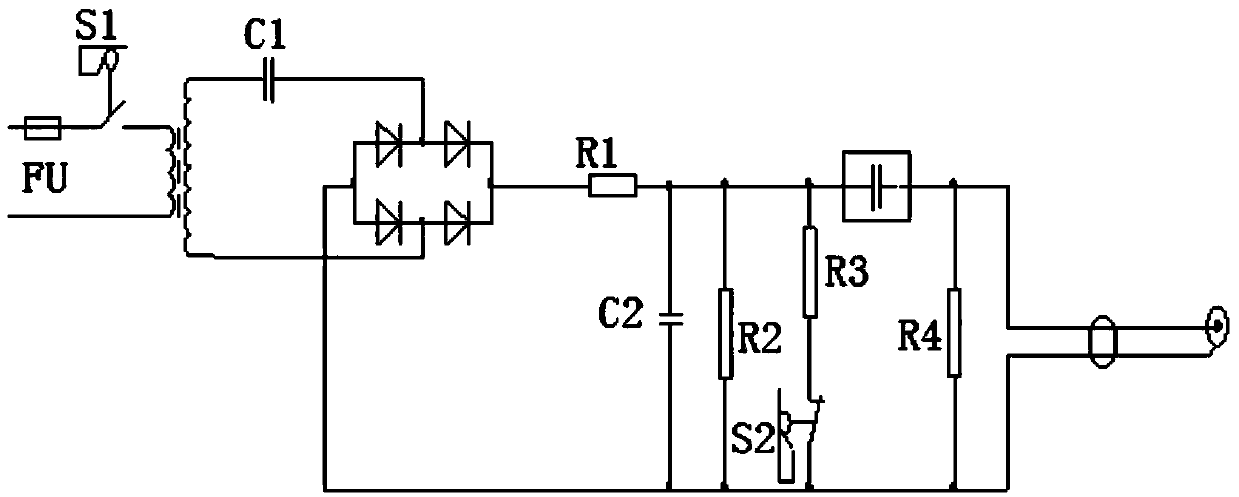

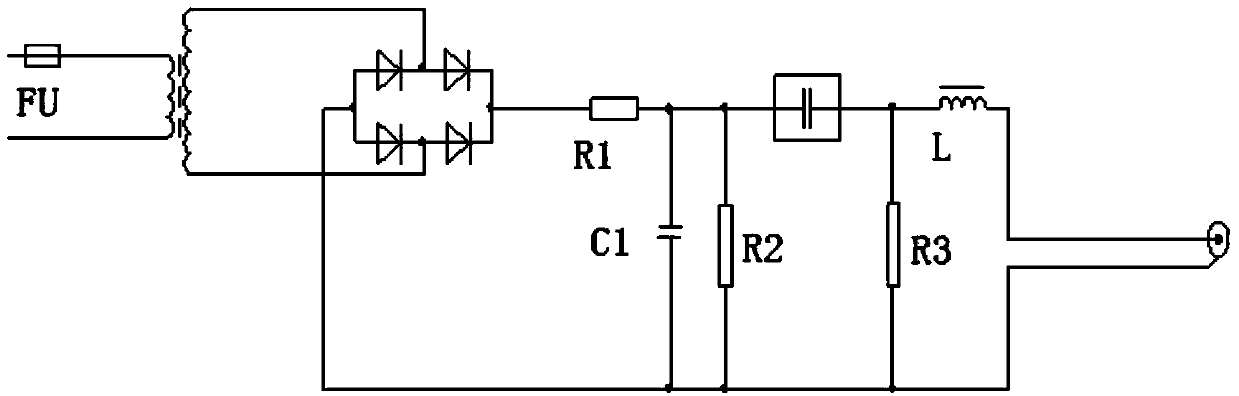

[0016] Such as figure 1 As shown, a high-energy electronic igniter circuit of the present invention includes a step-up transformer, a resistor R1, a resistor R2, a resistor R3, a capacitor C1, a capacitor C2, a switch S1, a switch S2, a discharge tube and a rectifier circuit, the switch S1 and the booster The primary coil of the transformer is connected in series, the capacitor C1 is connected in series with the secondary coil of the step-up transformer, the input terminal of the rectifier circuit is connected with the secondary coil of the step-up transformer, and the output terminal of the rectifier circuit is respectively connected with one end of the resistor R1 and one end of the capacitor C2 , the other end of the resistor R1 is connected to the other end of the capacitor C2, the resistor R2 is connected in parallel with the capacitor C2, the switch S2 is connected in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com