Rapid hydrogen measurement device and hydrogen measurement method for aluminium alloy

A technology for aluminum alloy and aluminum alloy melt, which is applied in measuring devices, specific gravity measurement, instruments, etc., can solve the problems of high maintenance cost, unsuitable for on-line hydrogen measurement, and high equipment cost, and achieves low equipment cost and maintenance cost. Fast, simple-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0031] Taking an aluminum-copper alloy as an example, the present invention will be further described.

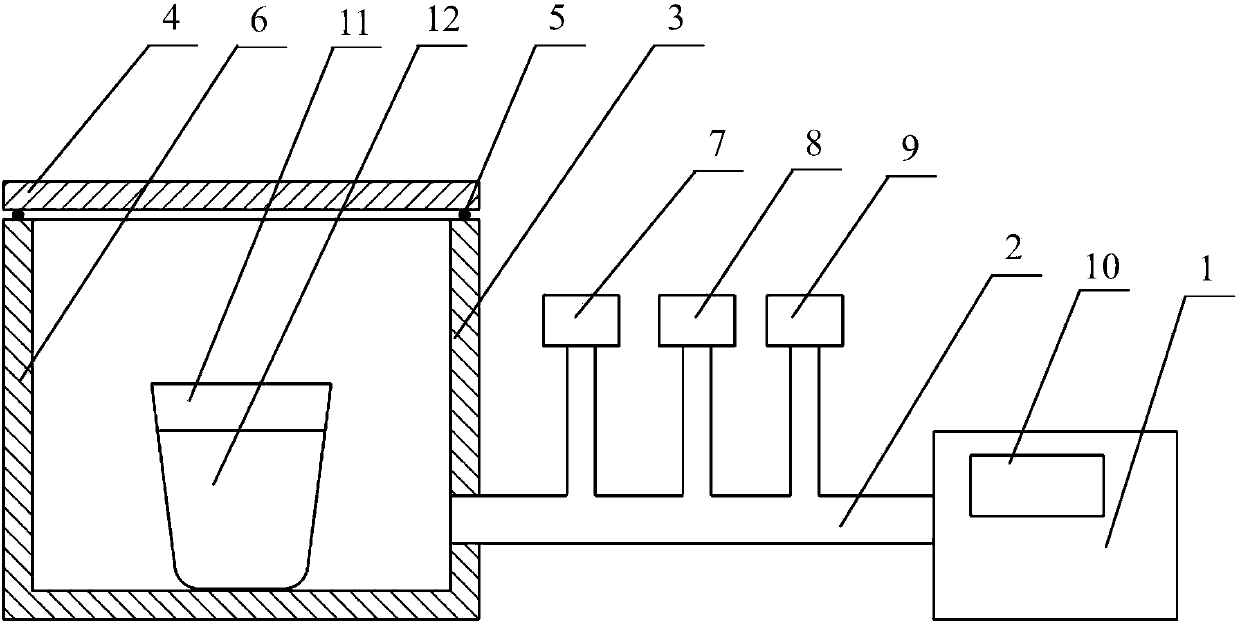

[0032] Such as figure 1 As shown, an aluminum alloy rapid hydrogen measuring device includes a vacuum pump 1, a vacuum chamber 3, a vacuum gauge 7, a vacuum pressure relief valve 8, a vacuum degree regulating valve 9 and a crucible 11; the vacuum chamber 3 is composed of a cover plate 4 and a vacuum The container 6 is composed of a sealing ring 5 between the cover plate 4 and the vacuum container 6; the vacuum pump 1 communicates with the vacuum chamber 3 through the vacuum pipeline 2, the vacuum pressure relief valve 8, the vacuum degree regulating valve 9 and the vacuum gauge 7 They are respectively arranged on the vacuum pipeline 2, and the vacuum pressure relief valve 8, the vacuum degree regulating valve 9 and the vacuum gaug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com