A method for testing satellite electronic load

An electronic load and load testing technology, applied in the field of testing, can solve the problems of easy to miss the load state, poor time accuracy, easy to make mistakes, etc., to save development costs, improve efficiency, and avoid wrong settings or misoperations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

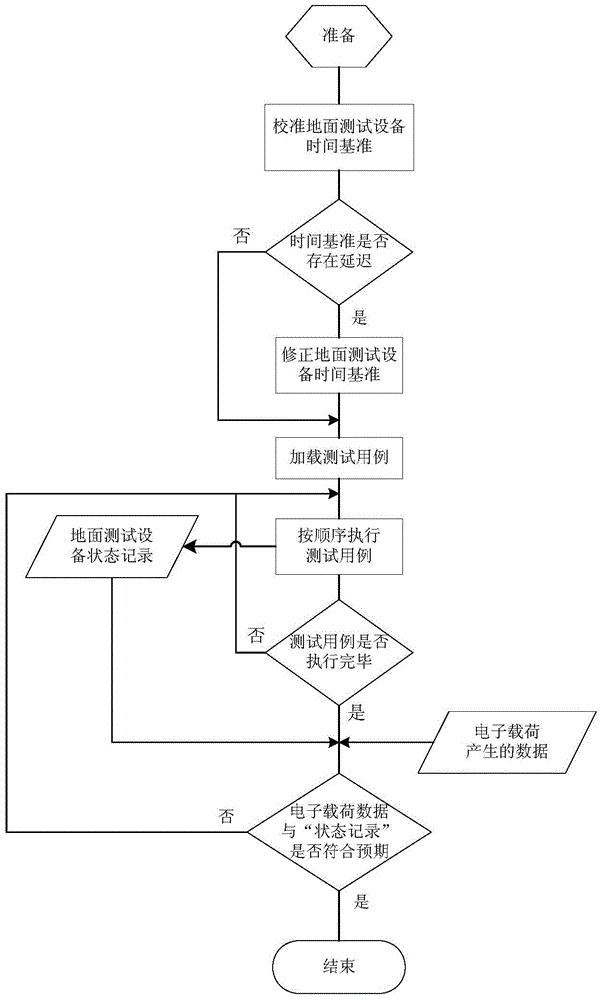

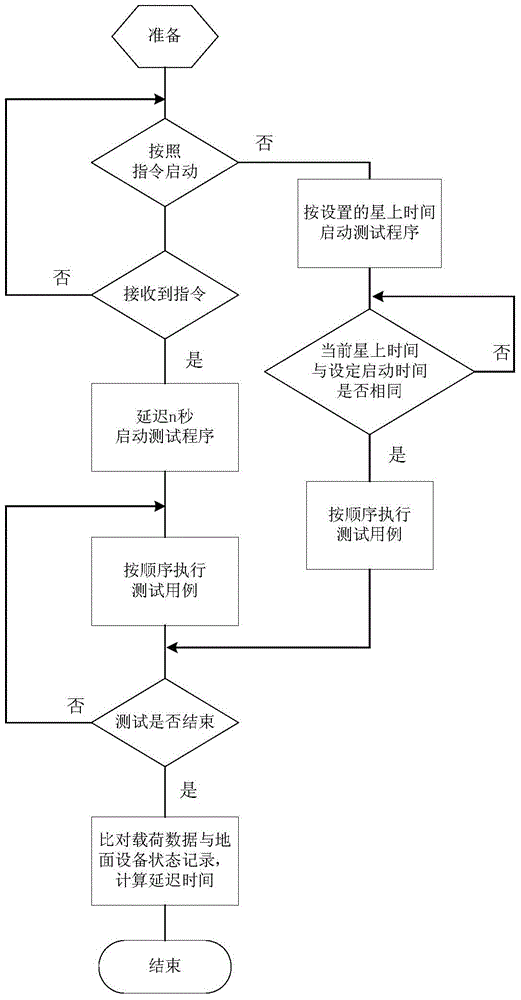

[0031] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The invention provides a satellite electronic load testing method. This method is realized on the basis of the existing satellite test network. For details, see "Design and Implementation of Automatic Test Software for Small Satellite Measurement and Control Subsystem", Mao Xinbai, Nankai University, Software Engineering Dissertation, 2012 and "Small Satellite Test Technology Development and Prospects", Li Peihua et al., Proceedings of the 2011 Small Satellite Technology Exchange Conference.

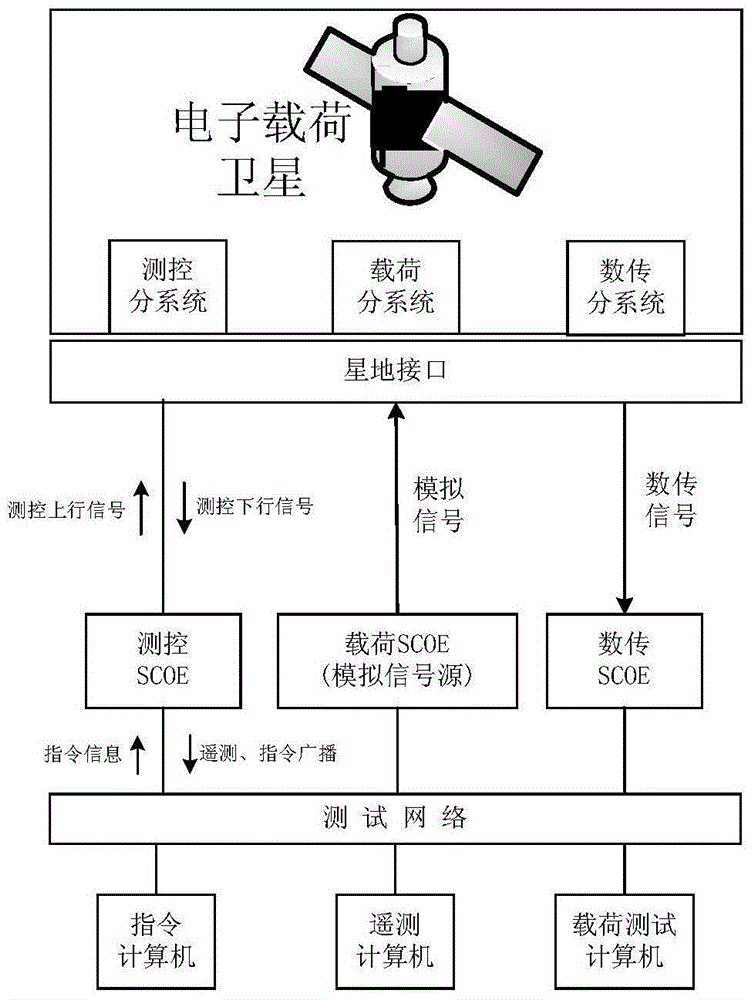

[0033] Such as figure 1 Shown is the device connection schematic diagram of the present invention, by figure 1It can be seen that the subsystems that have an interface relationship with the satellite electronic payload test include the measurement and control subsystem, the payload subsystem, and the data transmission subsystem. The gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com