Processing method of common green tea and green tea prepared by processing method

A processing method and technology for green tea, applied in the direction of tea processing before extraction, can solve the problems of scorched young leaves, uneven old and tender leaves, and mature leaves, and achieve good tea shape, uniform length, and low tea powder rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

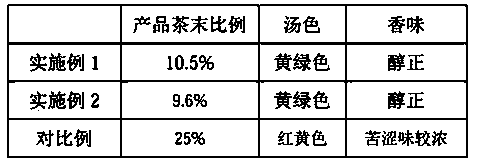

Examples

Embodiment 1

[0022] A processing method of bulk green tea includes the following steps:

[0023] 1) Cut the picked fresh tea leaves, cut them into 2-3cm long segments, and then spread them for 4-6 hours until the moisture content is ≤85%;

[0024] 2) After spreading the green tea, use the drum or steam method to finish the greening. The temperature of the greening is controlled at 180-220℃, the time is 3-4min, and then the drying equipment is added and dried at 75-80℃. The moisture content in the tea leaves is less than 50%, and then the tea leaves are added to the cooler to cool to room temperature;

[0025] 3) Knead the tea leaves obtained in step 2) for 30-50 minutes, with a kneading pressure of 10-15 kg, until the tea leaves are kneaded into a ball, the hands are loosened and the tea juice overflows, and then the tea leaves are cooled, and then two After drying, the moisture content in the tea leaves is below 35%;

[0026] 4) Step 3) The obtained tea leaves are stacked and re-moisturized for ...

Embodiment 2

[0030] A processing method of bulk green tea includes the following steps:

[0031] 1) Cut the picked fresh tea leaves, cut them into 2-3cm long segments, and then spread them for 4-6 hours until the moisture content is ≤85%;

[0032] 2) After spreading the green tea, use the drum or steam method to finish the greening. The temperature of the greening is controlled at 200℃ for 4min. Then add the drying equipment and dry it at 75-80℃ to reach the moisture in the tea. The content is less than 50%, then add the tea leaves to the cooler to cool to room temperature;

[0033] 3) Knead the tea leaves obtained in step 2) for 30-50 minutes, until the tea leaves are kneaded into a ball, the hands are loosened automatically, and the tea juice overflows, then the tea leaves are cooled, and the tea leaves are dried for a second time until the The moisture content is below 35%;

[0034] 4) Step 3) The obtained tea leaves are stacked and re-moisturized for more than 30 minutes until the leaves are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com