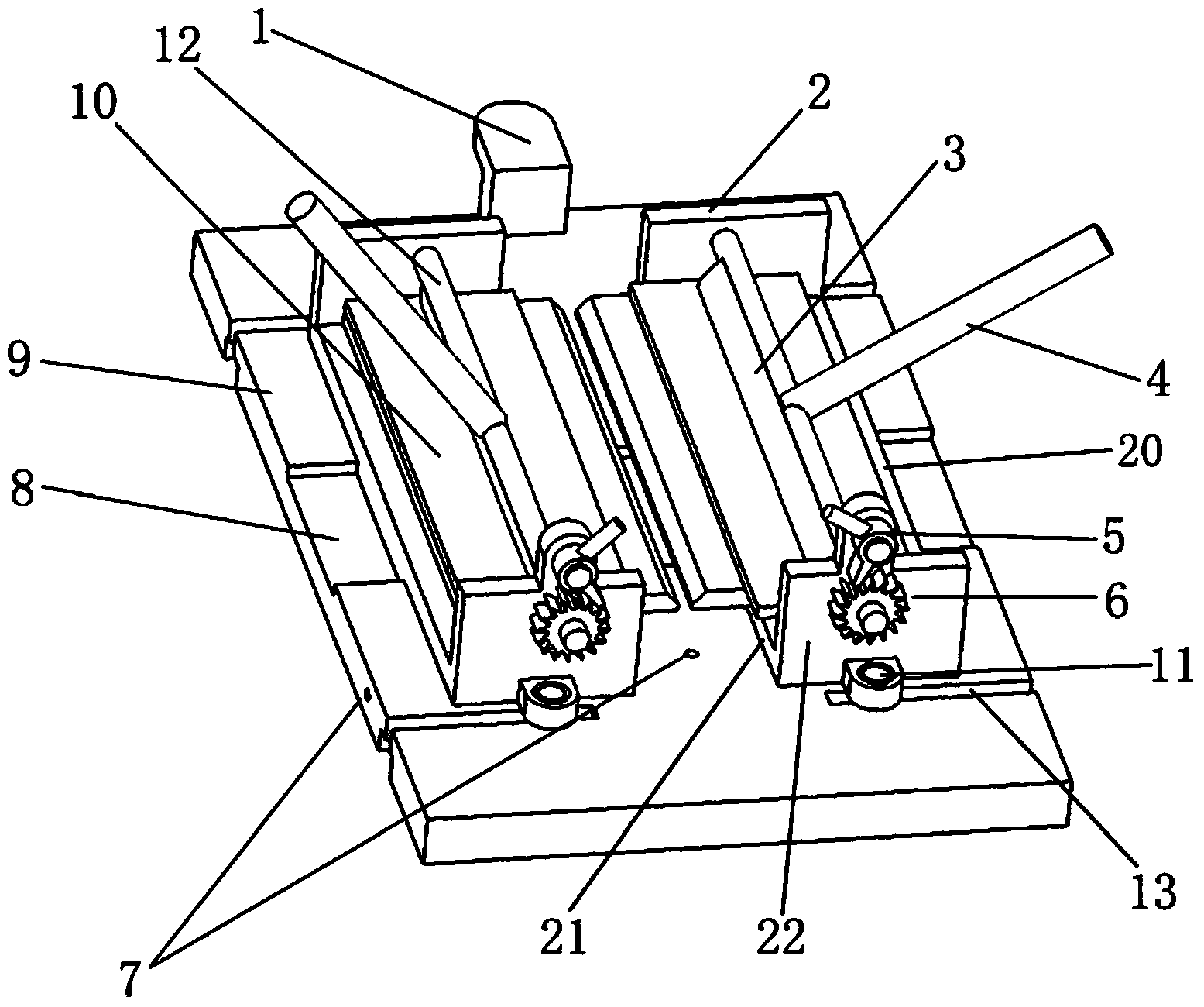

Welding clamping device

A welding clip and positioning slider technology, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of long time, affect processing efficiency, affect welding efficiency, etc., achieve easy clamping and unloading, and improve welding quality. , The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0026] This embodiment is the same as Embodiment 1, and the difference is that in this embodiment, the clamping device also includes two sets of linear modules respectively installed on both sides of the positioning slider, and each set of linear modules includes Servo motor and ball screw, the ball screw has two screw rods with opposite helical directions, each screw rod is provided with a nut; the two positioning sliders are respectively connected with the two nuts of the ball screw; the ball screw is connected with the servo motor . The ball screw is installed on the bottom plate 9, parallel to the chute, and the servo motor drives the ball screw to rotate, thereby driving the two positioning sliders 2 that are oppositely arranged to approach or move away from each other.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com