Slugging machine for plastic bottle

A technology for plastic bottles and cutting machines, which is applied in metal processing and other directions, can solve the problems of difficult debugging and complex structure, and achieve the effects of stable surface quality of the cut, simplified mechanism and simple debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

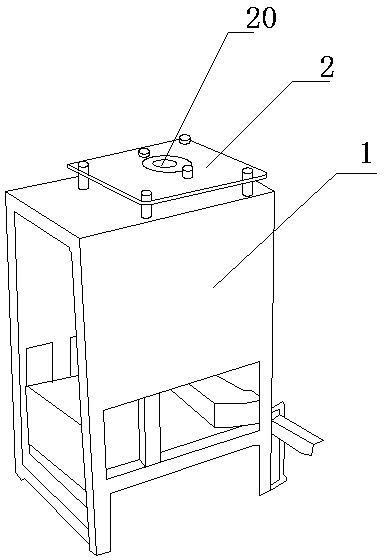

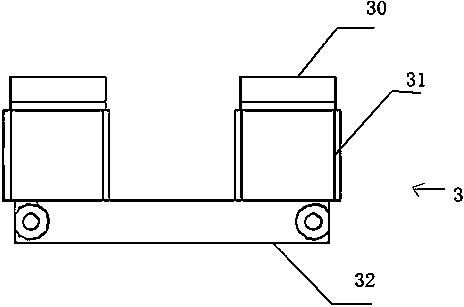

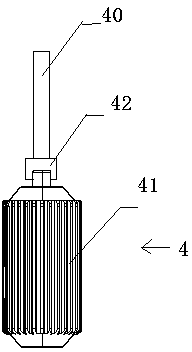

[0050] What present embodiment provides is the notch machine that is used for plastic bottle notch, and notch machine comprises frame 1, cutter mechanism 3, plastic bottle fixed frame 2 and driving mechanism, and described plastic bottle fixed frame 2 is installed on frame 1 top, The plastic bottle fixing frame 2 is provided with a plastic bottle feeding port 20, and the cutter mechanism 3 and the driving mechanism are all fixed on the frame 1, and the driving mechanism includes a cutter rotating mechanism 4 and a cutter opening and closing mechanism 5, and the plastic bottle The feeding port 20 is arranged facing the cutter mechanism 3 .

[0051] The plastic bottle fixing frame 2 is fixed on the frame 1 by bolts. There are multiple plastic bottle fixing frames 2. The size of the plastic bottle feeding inlet 20 of each plastic bottle fixing frame 2 is different, and workers can choose according to different specifications of plastic bottles. The plastic bottle fixing frame of ...

Embodiment 2

[0059]This embodiment is basically the same as Embodiment 1, except that the up and down drive mechanism of the conical push block is different. The up and down drive mechanism of the conical push block in this embodiment includes a cam shaft 514, a cam 515, a cam swing arm 516 and a cam top The rod 517 and the cam 515 are sleeved on the camshaft 514, one end of the cam swing arm 516 is hinged on the frame 1, and the other end is connected with the cam push rod 517, the cam swing arm 516 is pressed on the cam 515, and the cam swing arm 516 is connected A cam extension spring 518 is arranged, and the other end of the cam extension spring 518 is connected on the frame 1, and the bottom of the cam push rod 517 is connected with the tapered push block 51, and the camshaft 514 is provided with a crank handle 519. In this embodiment, the extension spring 53 is no longer used to urge the arc arm 50 to return, but a volute spring is used to urge the arc arm to return. The worm spring i...

Embodiment 3

[0061] This embodiment is basically the same as Embodiment 1, except that the upper and lower drive mechanisms of the conical push block are different. on the rack. The opening and closing action of the cutter is realized by controlling the extension and retraction of the ejector rod of the cylinder to control the up and down movement of the conical push block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com