Co9S8/graphene composite hydrogen storage material and preparation method thereof

A technology of graphene composite and hydrogen storage materials, which is applied in chemical instruments and methods, hydrogen production, cobalt compounds, etc., can solve the problems of poor cycle stability, low performance, and low hydrogen storage performance, and achieve high safety and preparation Simple process and excellent electrochemical hydrogen storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

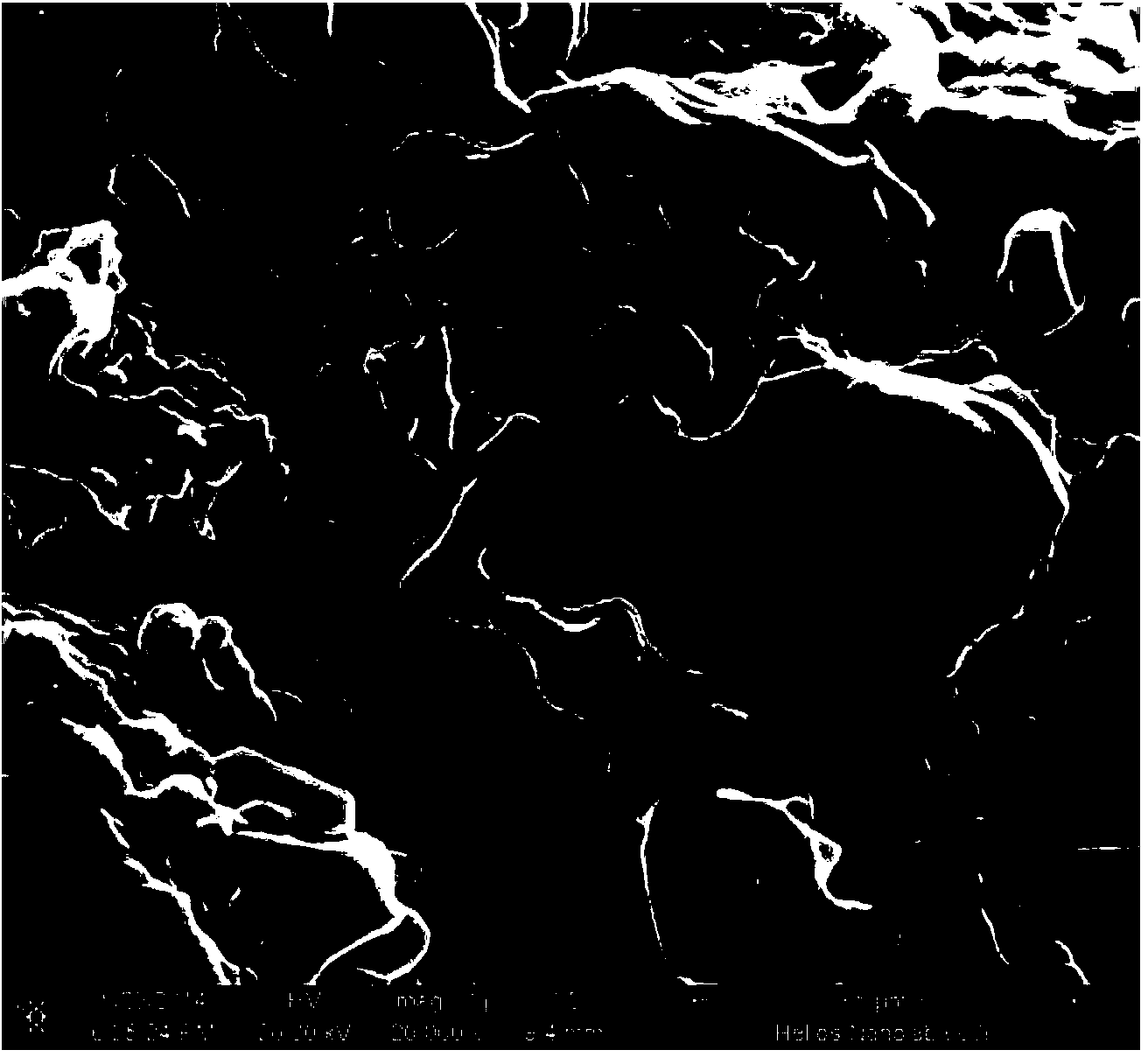

[0017] Specific implementation mode one: the Co of this embodiment mode 9 S 8 / Graphene composite hydrogen storage material is a layered structure, Co 9 S 8 Attached to the surface of graphene sheets, where graphene and Co 9 S 8 The molar ratio is 1:(5~7).

specific Embodiment approach 2

[0018] Embodiment 2: Preparation of the Co described in Embodiment 1 9 S 8 The method for / graphene composite hydrogen storage material, carries out as follows:

[0019] 1. Mix cobalt powder and sulfur powder according to the molar ratio of 1: (0.9-1.1) to obtain mixed powder I;

[0020] 2. Press ZrO 2 The mass ratio of the grinding ball to the mixed powder I is (10-15): 1, and the ZrO 2 Grinding balls and mixed powder Ⅰ loaded with ZrO 2 Fill the lined ball milling tank with high-purity argon, and finally fix the ball milling tank in the ball mill, and mill it for 8-12 hours at the speed of the ball mill at 600-800 rpm. After the ball milling is completed and the ball milling tank is cooled to room temperature, the obtained co 9 S 8 powder;

[0021] 3. According to graphene and Co 9 S 8 The molar ratio of the powder is 1: (5-7) for mixing to obtain the mixed powder II;

[0022] 4. Press ZrO 2 The mass ratio of the grinding ball to the mixed powder II is (15-20): 1, ...

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 2 in that the high-purity argon described in steps 2 and 4 refers to argon with a mass percentage concentration greater than 99.999%. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com