A kind of synthetic method of disperse blue 77

A synthesis method and a technology for dispersing blue, applied in the field of blue dye synthesis technology, can solve the problems of increased waste water, large consumption of aniline, increased content of aniline, etc., and achieve reduced production cost, low consumption of aniline, and fast color absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

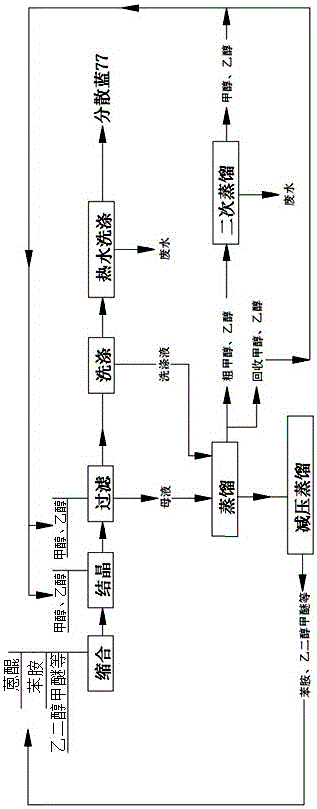

[0033] Embodiment one: see figure 1 .

[0034] The invention discloses a synthetic method of disperse blue 77, comprising the steps of:

[0035] a. Add the mixed solution of aniline and ethylene glycol methyl ether in the reaction vessel, stir, and after detection, analysis and calculation, drop a certain amount of mixed solution of aniline and ethylene glycol methyl ether again, and the total volume of the aniline dropped into twice is 100 Milliliters, the total volume of ethylene glycol methyl ether is 500 milliliters;

[0036] b. Raise the temperature to 30°C, add 1,8-dihydroxy-4,5-dinitroanthraquinone at 30°C, and keep the molar ratio of aniline to 1,8-dihydroxy-4,5-dinitroanthraquinone at 1 :4;

[0037] c. After the addition, the temperature was raised to 110°C. At about 110°C, the material began to undergo condensation reaction, and the temperature was kept for 4 hours;

[0038] d. Raise the temperature to 120°C and keep the temperature at 120°C for 8 hours;

[...

Embodiment 2

[0047] a. Add the mixed solution of aniline and ethylene glycol ether in the reaction vessel, stir, after detection analysis calculates, drop into the mixed solution of a certain amount of aniline and ethylene glycol ether again, the total volume of the aniline that drops into twice is 200 milliliters, The total volume of ethylene glycol methyl ether is 400 milliliters;

[0048] b. Raise the temperature to 35°C, add 1,8-dihydroxy-4,5-dinitroanthraquinone at 35°C, and keep the molar ratio of aniline to 1,8-dihydroxy-4,5-dinitroanthraquinone at 1 :7;

[0049] c. After the addition, the temperature was raised to 115°C. At about 115°C, the material began to undergo condensation reaction, and the temperature was kept for 2 hours;

[0050] d. Heat up to 130°C and keep warm for 4 hours;

[0051] e. Cool down to 75°C;

[0052] f. Cool the mixture of 1,8-dihydroxy-4,5-dinitroanthraquinone, aniline and ethylene glycol ethyl ether after the above condensation reaction to 75°C an...

Embodiment 3

[0059] a. Add the mixed solution of aniline and ethylene glycol in the reaction vessel, stir, and after detection, analysis and calculation, drop into a certain amount of mixed solution of aniline and ethylene glycol again, the total volume of the aniline dropped into twice is 400 milliliters, ethylene glycol The total volume of alcohol is 200 ml;

[0060] b. Raise the temperature to 40°C, add 1,8-dihydroxy-4,5-dinitroanthraquinone at 40°C, and keep the molar ratio of aniline to 1,8-dihydroxy-4,5-dinitroanthraquinone at 1 :15;

[0061] c. After the addition, the temperature was raised to 115°C. At about 115°C, the material began to undergo condensation reaction, and the temperature was kept for 1 hour;

[0062] d. Heat up to 130°C and keep warm at 130-140°C for 2 hours;

[0063] e. Cool down to 80°C;

[0064] f. Cool the mixture of 1,8-dihydroxy-4,5-dinitroanthraquinone, aniline and ethylene glycol ethyl ether after the above condensation reaction to 80°C and put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com