Polyolefin silane crosslinking catalyst master batch and preparation method thereof for room temperature crosslinking

A technology of cross-linking catalyst and polyolefin silane, which is applied in the field of plastic particles and their preparation, can solve the problems of poor reliability and uniformity of cross-linking, long boiling time or sauna time, and difficulty in meeting the requirements of cross-linking degree. Continuity and reliability, avoiding boiling or sauna cross-linking procedures, preventing localized over-cross-linking effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

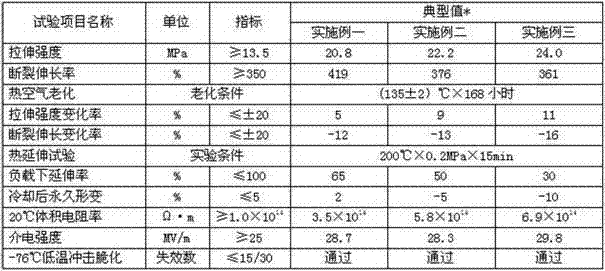

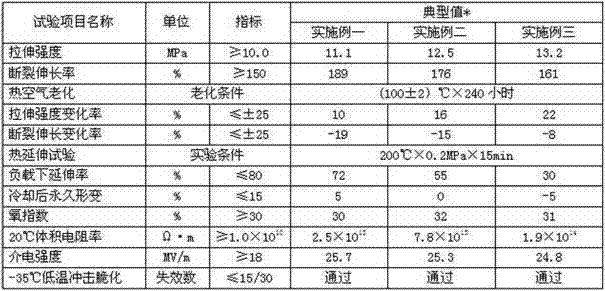

Embodiment 1

[0018] First choose the polyolefin elastomer of 80 parts by weight; The ethylene-vinyl acetate copolymer resin of 20 parts by weight; The crosslinking catalyst of 0.1 parts by weight; The anti-precrosslinking agent of 0.5 parts by weight; The antioxidant of 2 parts by weight; parts of processing aids.

[0019] Then, put the polyolefin elastomer and ethylene-vinyl acetate copolymer resin in a high-speed mixer, and stir at a high speed until the temperature is not lower than 80°C;

[0020] After that, add the cross-linking catalyst into the high-speed mixer and stir for 3 to 5 minutes;

[0021] After that, put the anti-precrosslinking agent, antioxidant and processing aid into the high-speed mixer and continue stirring for 3 to 5 minutes;

[0022] Finally, the above-mentioned stirred materials are fed into a twin-screw mixing extruder with four temperature zones by a feeder, extruded into granules, and dried to obtain a polyolefin silane cross-linking catalyst parent for room t...

Embodiment 2

[0032] First choose the polyolefin elastomer of 90 parts by weight; The ethylene-vinyl acetate copolymer resin of 10 parts by weight; The crosslinking catalyst of 0.3 parts by weight; The anti-precrosslinking agent of 1.0 parts by weight; The antioxidant of 4 parts by weight; parts of processing aids.

[0033] Then, put the polyolefin elastomer and ethylene-vinyl acetate copolymer resin in a high-speed mixer, and stir at a high speed until the temperature is not lower than 80°C;

[0034] After that, add the cross-linking catalyst into the high-speed mixer and stir for 3 to 5 minutes;

[0035] After that, put the anti-precrosslinking agent, antioxidant and processing aid into the high-speed mixer and continue stirring for 3 to 5 minutes;

[0036] Finally, the above-mentioned stirred materials are fed into a twin-screw mixing extruder with four temperature zones by a feeder, extruded into granules, and dried to obtain a polyolefin silane cross-linking catalyst parent for room t...

Embodiment 3

[0046]First choose the polyolefin elastomer of 85 parts by weight; The ethylene-vinyl acetate copolymer resin of 15 parts by weight; The crosslinking catalyst of 0.5 parts by weight; The anti-precrosslinking agent of 1.5 parts by weight; The antioxidant of 6 parts by weight; parts of processing aids.

[0047] Then, put the polyolefin elastomer and ethylene-vinyl acetate copolymer resin in a high-speed mixer, and stir at a high speed until the temperature is not lower than 80°C;

[0048] After that, add the cross-linking catalyst into the high-speed mixer and stir for 3 to 5 minutes;

[0049] After that, put the anti-precrosslinking agent, antioxidant and processing aid into the high-speed mixer and continue stirring for 3 to 5 minutes;

[0050] Finally, feed the above-mentioned stirred material into a twin-screw mixing extruder with four temperature zones, extrude it into granules, and obtain a polyolefin silane cross-linking material for room temperature cross-linking after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com