Water-soaking-resistant priming finishing paint and preparation method thereof for glass water ball

A technology of glass water polo and primer, which is applied in the direction of coating, etc., can solve the problems of poor durability, discoloration, and peeling, and achieve the effects of excellent chemical resistance, fast surface drying, and long activation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]

[0045] The IPDI type trimer curing agent described in the following examples refers to isophorone diisocyanate (IPDI) trimer curing agent (Z4470 Bayer Chemical).

[0046] Ethylene-vinyl acetate copolymer polymer (EVA150 Mitsui, Japan)

[0047] 4-tert-butylphenol formaldehyde resin (2402, Haixier (Xiamen) Chemical)

[0048] Polymethyl methacrylate (980N, Asahi Kasei, Japan)

[0049] Hydroxy Acrylic Resin (UR-147 Youda Chemical)

[0050] Rutile Titanium Dioxide (CR501 Jinzhou Titanium Industry)

[0051] Dispersant (BYK-163 BYK)

[0052] Defoamer (5500 Hymings Chemical)

[0053] Leveling agent (BYK-306 BYK company)

[0054] Precipitated barium sulfate (3000 mesh barium sulfate Shanghai Yuejiang)

[0055] Sericite (A4 Chuzhou Wanqiao)

[0056] Anti-settling (SUPER Huanqi Chemical)

[0057] Drier (T-12 US Gas)

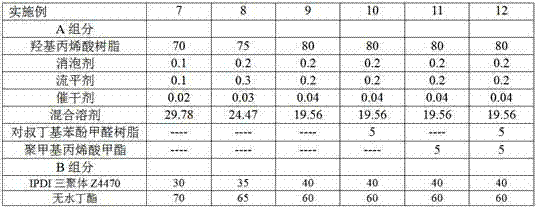

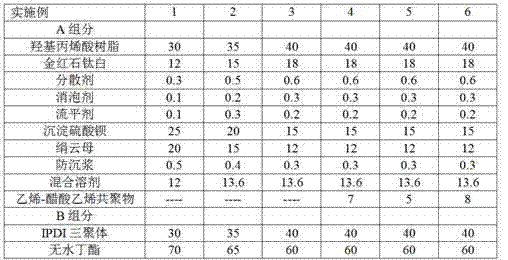

[0058] Table 1 The formula ratio of the primer components of Example 1 to Example 6 (unit: Kg)

[0059]

[0060] Preparation method of component A: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com