Nano-enhanced transition layer-free organosilicon low surface energy antifouling coating and preparation method thereof

A nano-enhanced, low surface energy technology, applied in antifouling/underwater coatings, coatings, biocide-containing paints, etc., can solve problems such as poor adhesion, low strength, complex construction, etc., to reduce adhesion, The effect of weakening the binding force and easy to fall off by itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Add 80 parts of α, ω-dihydroxy polydimethylsiloxane with a viscosity of 10000mPa·s and 8 parts of fumed silicon dioxide into the dispersion tank of the dispersing machine in proportion, disperse at 4000rpm for 30min at high speed, and then add 2 parts The multi-walled carbon nanotubes continued to disperse at high speed for 15 minutes to obtain nanometer pre-dispersed slurry;

[0065] Component A Add each composition to the dispersing tank of the dispersing machine sequentially in proportion, stir and disperse at a high speed of 4000 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0066] Components B and C are mixed according to the ratio and canned for use.

[0067] Before use, mix and stir evenly according to the ratio of A:B:C=20:4:1, and obtain a silicone low surface energy antifouling coating after coating and curing.

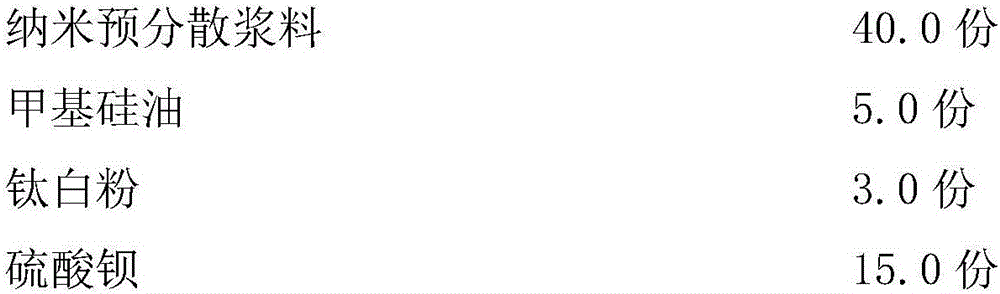

[0068] The composition of group A:

[0069]

[0070]

[0...

Embodiment 2

[0079] Add 75 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s and 8 parts of fumed silicon dioxide into the dispersion tank of the dispersing machine in proportion, disperse at 4000rpm for 30min at high speed, and then add 2 parts The single-walled carbon nanotubes continued to disperse at a high speed for 15 minutes to obtain a nano-predispersed slurry;

[0080] Component A Add each composition to the dispersing tank of the dispersing machine sequentially in proportion, stir and disperse at a high speed of 5000 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0081] Components B and C are mixed according to the ratio and canned for use.

[0082] Before use, mix and stir evenly according to the ratio of A:B:C=18:4:1, and obtain a silicone low surface energy antifouling coating after coating and curing.

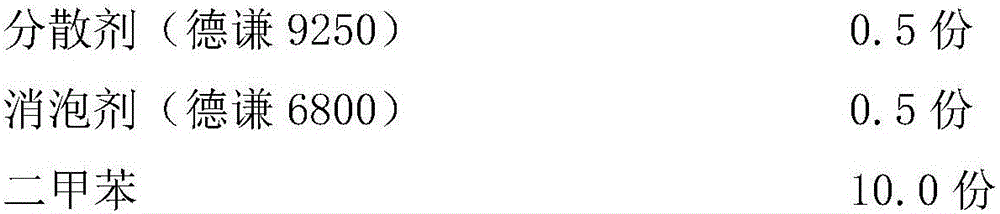

[0083] The composition of group A:

[0084]

[0085] Component...

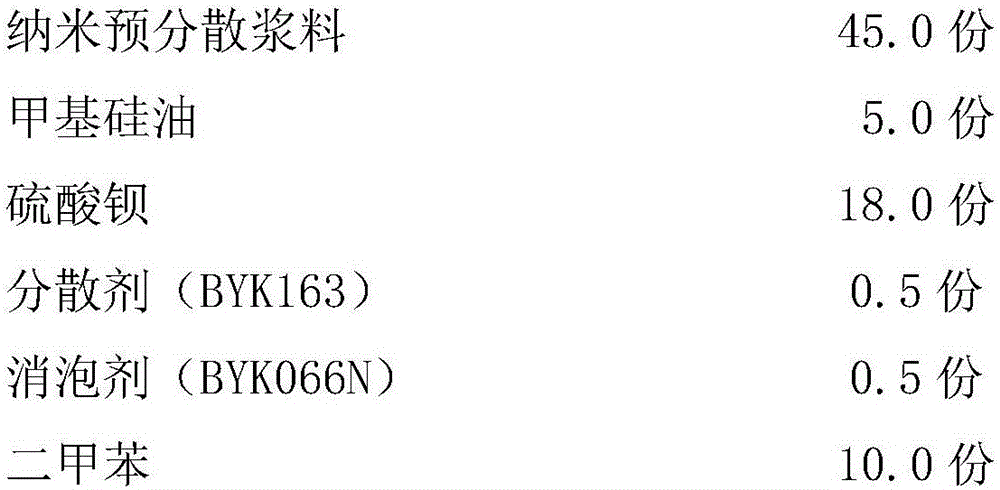

Embodiment 3

[0093] Proportionally, 50 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 10000mPa·s and 40 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2800mPa·s (purchased from Shandong University Yi Chemical Co., Ltd.) and 6 parts of fumed silica were added to the dispersing tank of the disperser, dispersed at a high speed for 30 minutes at 3500 rpm, then added 4 parts of nano-zinc oxide and continued to disperse at a high speed for 15 minutes to obtain a nano-predispersed slurry;

[0094] For component A, add each composition into the dispersing tank of the dispersing machine in sequence in proportion, stir and disperse at a high speed of 3500 rpm for 30 minutes, and then grind it with a sand mill until the fineness is less than 40 μm, then pack it into a tank for use.

[0095] Components B and C are mixed according to the ratio and canned for use.

[0096] Before use, mix and stir evenly according to the ratio of A:B:C=16:3:0.5, and obtain a silicone lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com