M10 hot-dip galvanized screw bolt

A full-threaded, hot-dip galvanized technology, applied in bolts, threaded fasteners, screws, etc., can solve the problems of short corrosion resistance life and limited use occasions, and achieve long corrosion resistance life, large limitations, and coordination. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

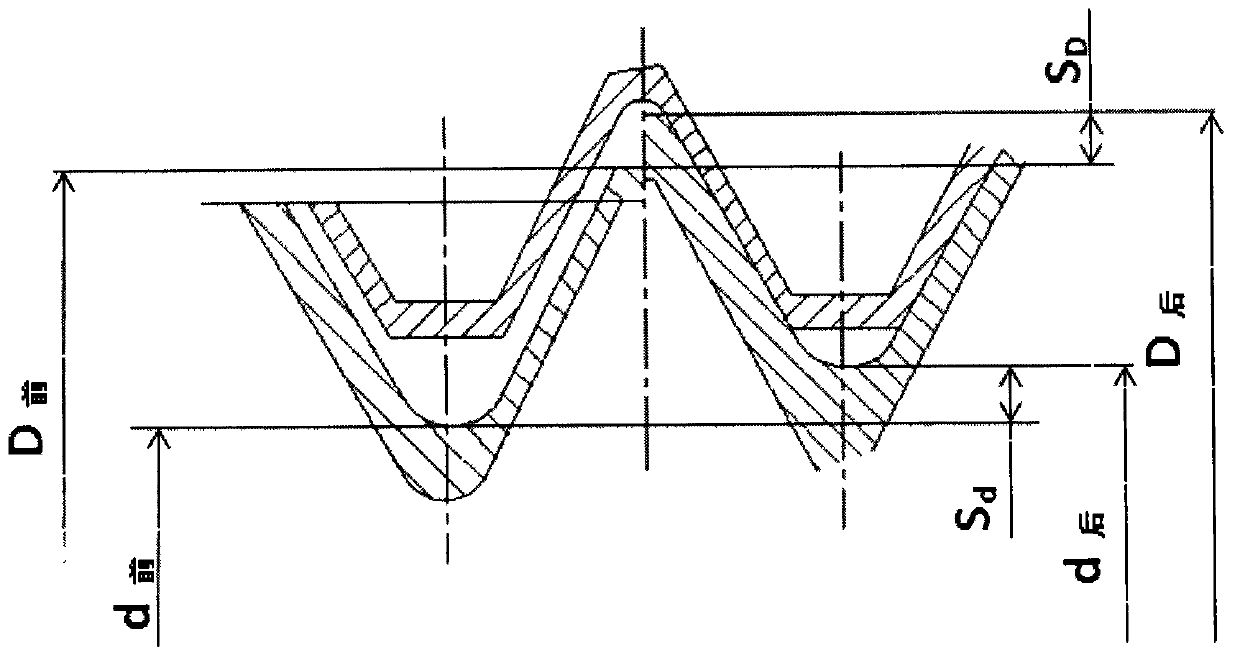

[0021] Embodiment one: see figure 1 As shown, a M10 hot-dip galvanized fully threaded bolt is formed from raw materials through drawing, cutting, piercing, hexagonal cutting, thread rolling, and galvanizing.

[0022] The raw material is cast iron wire with a diameter of 9.5 mm.

[0023] The diameter of the cast iron wire after drawing is 8.6-8.63mm.

[0024] The diameter of the drawn cast iron wire after pier head is 8.72-8.75mm.

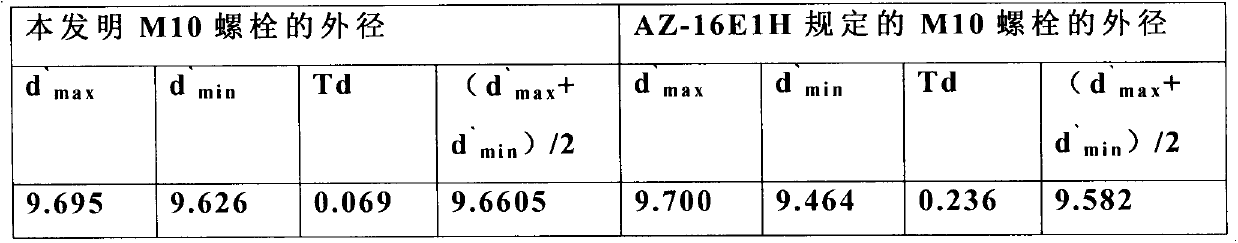

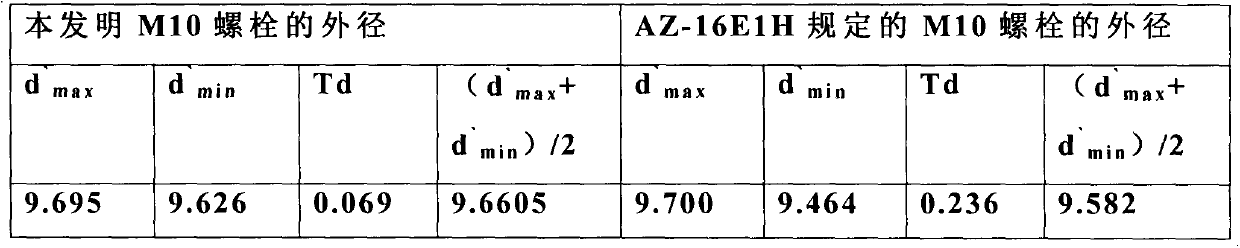

[0025] The external thread diameter of the M10 hot-dip galvanized full-thread bolt is composed of two parts: the size of the external thread before plating and the thickness S of the galvanized layer. The external thread diameter includes the external thread major diameter D and the external thread minor diameter d. The external thread Dimension D before plating of major diameter D 前 9.626 ~ 9.695mm, galvanized layer thickness S D 54~65μm, size D after plating 后 It is 9.68 ~ 9.76mm.

[0026] Dimension d before plating of the minor diameter d o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com