High-power LED (Light Emitting Diode) phase-change temperature control device with heat pipes

A technology for temperature control devices and LED packages, applied in the field of lighting, can solve the problems of reducing the temperature of LED chips, large volume changes in liquid-gas phase transitions, and additional energy consumption of active cooling systems, to achieve enhanced melting and solidification heat transfer, and improve effective Thermal conductivity, cost and weight reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

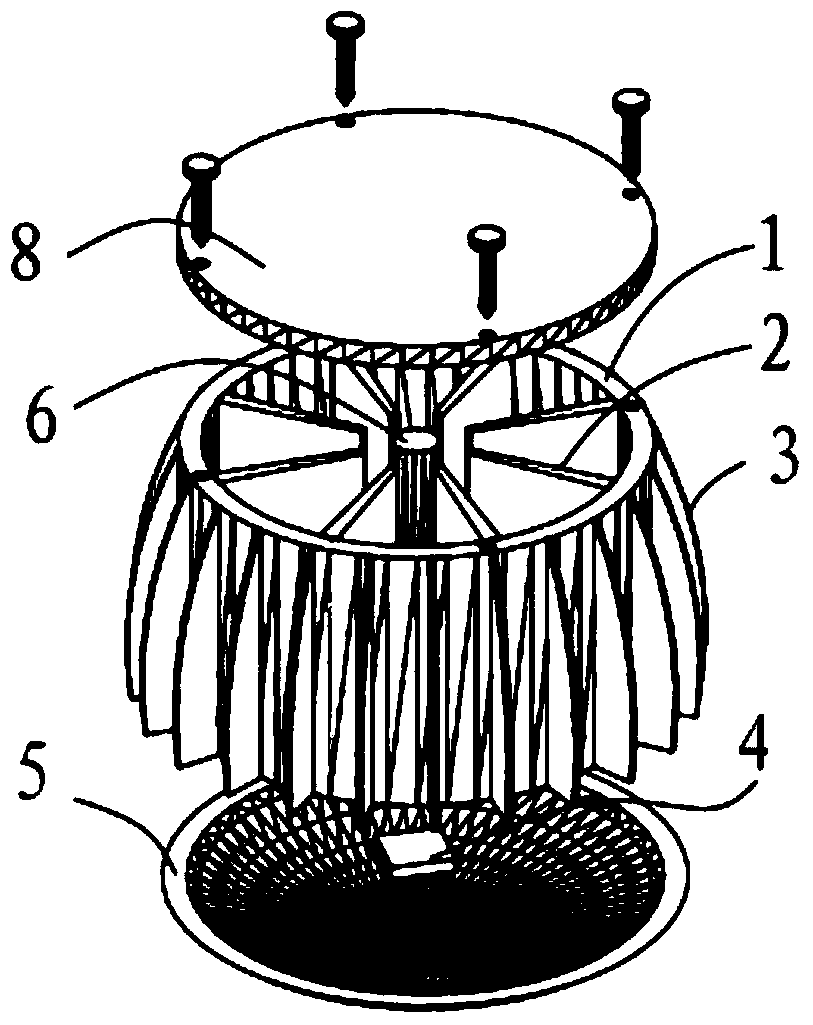

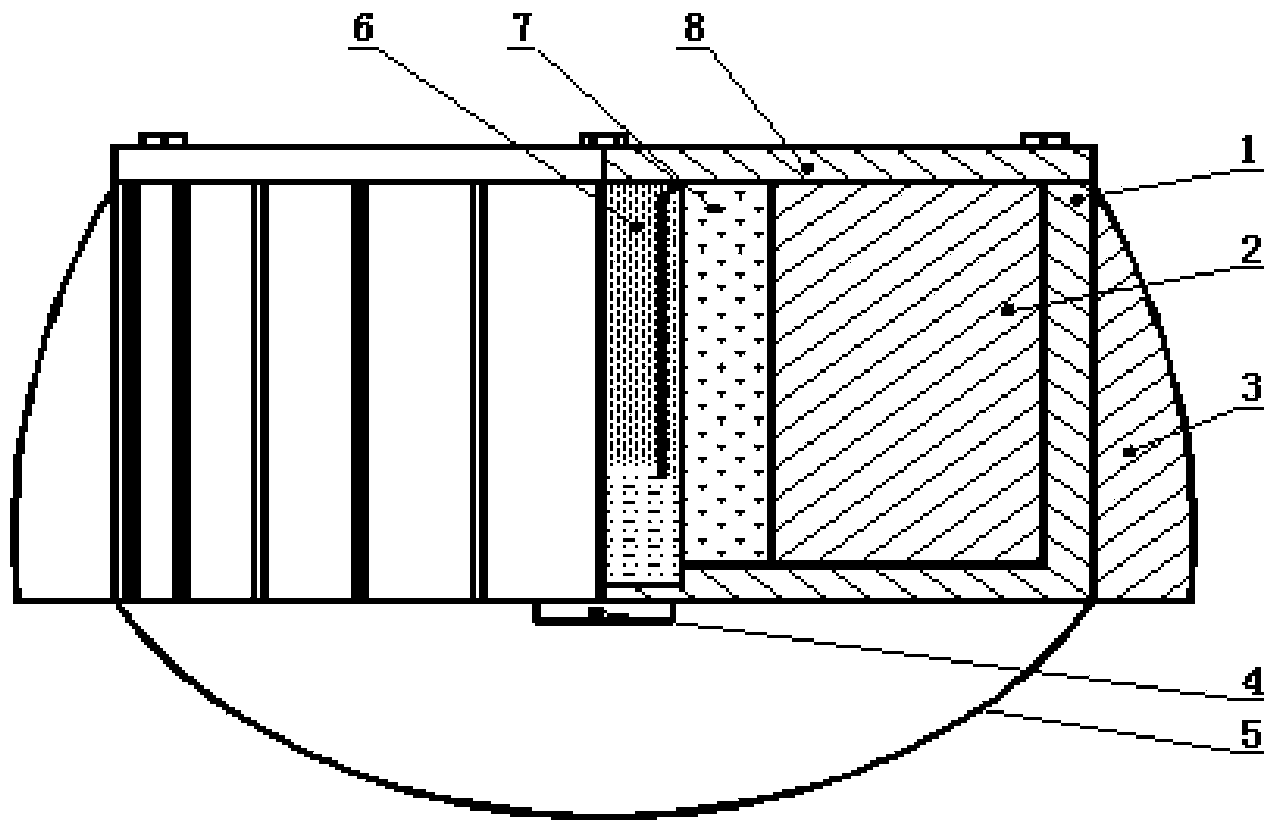

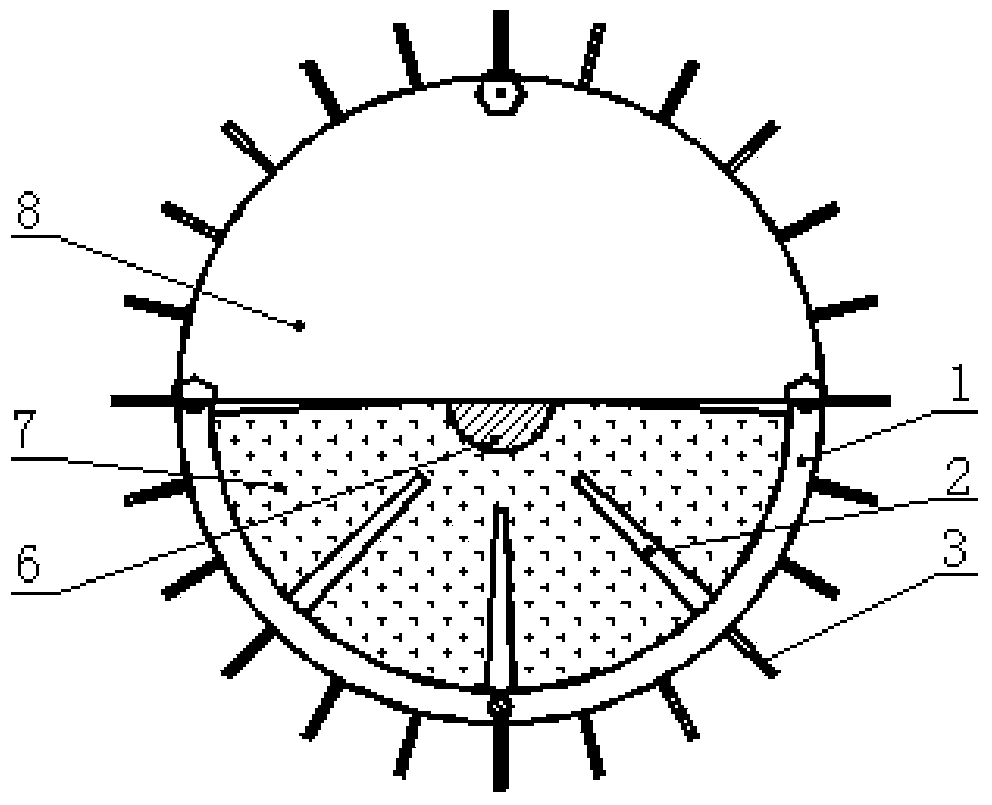

[0025] Such as figure 1 and figure 2 As shown, the high-power LED phase-change temperature control device with its own heat pipe in the present invention includes a circular heat sink cavity 1 with an LED package 4 at the bottom, and the LED package 4 is glued on by eutectic welding or heat-conducting silicone grease. The bottom of the heat sink cavity 1 and the bottom of the heat sink cavity 2 are also glued with a lens 5 for concentrating light and protecting the LED package 4; the lens 5 is made of transparent materials such as glass. The top of the heat sink cavity 1 is connected with a sealing end cover 8 by welding, gluing or bolts; a gravity heat pipe 6 filled with a working medium is arranged in the heat sink cavity 1, and the lower end of the gravity heat pipe 6 is connected by thread or interference The matching method is connected to the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com