Precision laser wavelength measurement device and precision laser wavelength measurement method

A laser wavelength, accurate measurement technology, applied in the measurement device, measurement optics, optical radiation measurement and other directions, can solve the problems of poor measurement stability, large error, low laser wavelength accuracy, etc., to achieve high accuracy, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

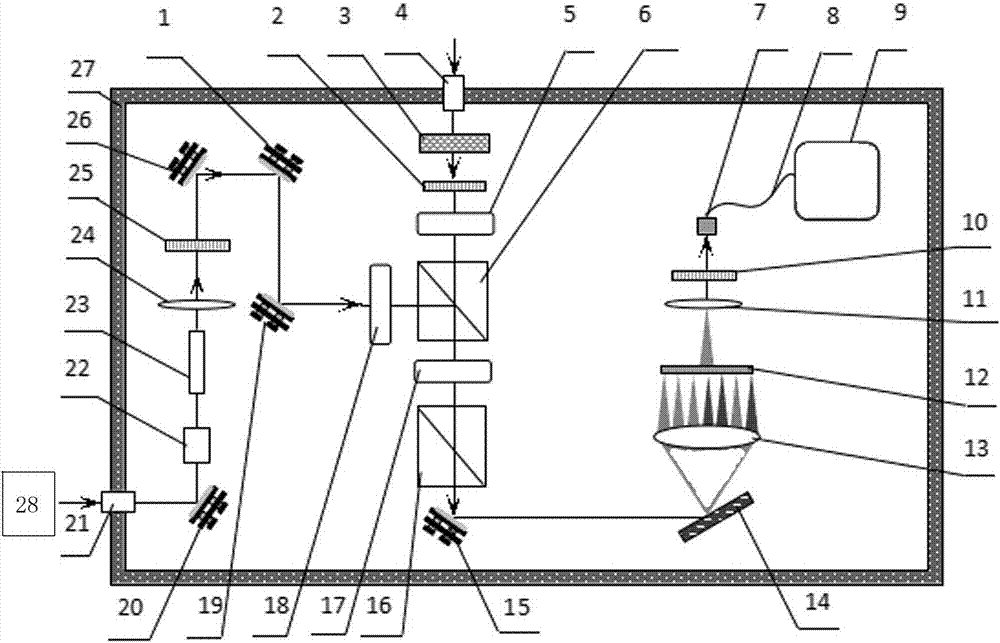

[0021] A device for accurately measuring the laser wavelength, comprising a femtosecond pulse laser 28, a PPLN crystal 22 sequentially located on the outgoing optical path of the femtosecond pulse laser 28, a photonic crystal fiber 23, a first convex lens 24, a first attenuation sheet 25 and a first Half-wave plate 18; Also comprise diaphragm 3, the second attenuation plate 2, the second half-wave plate 5, the first polarization beam splitter 6, the 3rd half-wave plate 17 and the second on the optical path of the laser to be measured in sequence Polarizing beam splitter 16; The first polarizing beam splitter 6 is also positioned on the outgoing optical path of the first half-wave plate 18; The position of the first half-wave plate 18 and the first polarizing beam splitter 6 should ensure that the first half-wave plate The optical path of the laser light emitted by 18 after being reflected by the first polarizing beam splitter 6 coincides with the optical path of the laser light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com