Method for measuring air ratio and heat capacity ratio by vibration of piston in single-end sealed cylinder

A specific heat capacity ratio and sealing air technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems that are difficult to realize, cannot be corrected quantitatively, and rotation uncertainty, etc., and achieve simple structure, simple and easy vibration method, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

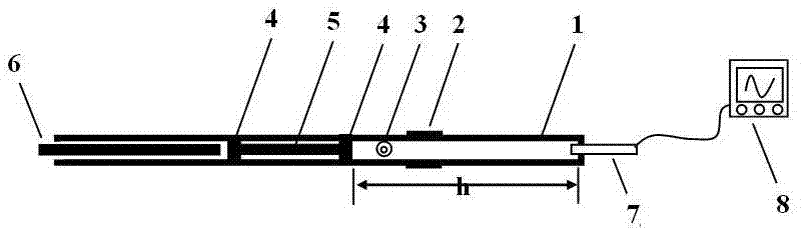

[0013] A cylinder 1 is made of hard transparent materials, such as glass and hard plastic, which can withstand pressure and have relatively small (negligible) deformation caused by pressure; the cylinder is divided into two sections, one of which is It is a hollow cylinder with a sealed bottom. A pressure sensor 7 is arranged at the bottom of the seal. The probe of the pressure sensor is located inside the cylinder 1. The signal line of the pressure sensor is connected to the digital oscilloscope 8, and the change of the pressure inside the cylinder is displayed by the digital oscilloscope. Curve, so as to measure its period; the other section of the cylinder 1 is a hollow tube, the inner diameter of the hollow tube and the hollow cylinder is the same, and its internal radius is recorded as r. Sealing gasket is arranged at place, and sealing gasket is the same as the sealing gasket of water cup, water valve etc., belongs to prior art.

[0014] The outer surface of cylinder 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com