Novel method for testing microwave complex permittivity of high-loss liquid and powder materials

A technology of complex permittivity and powder materials, which is applied in the field of complex permittivity test systems for high-loss liquids and powder materials, can solve problems such as cavity submersion, and achieve the effect of reducing requirements, good performance and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

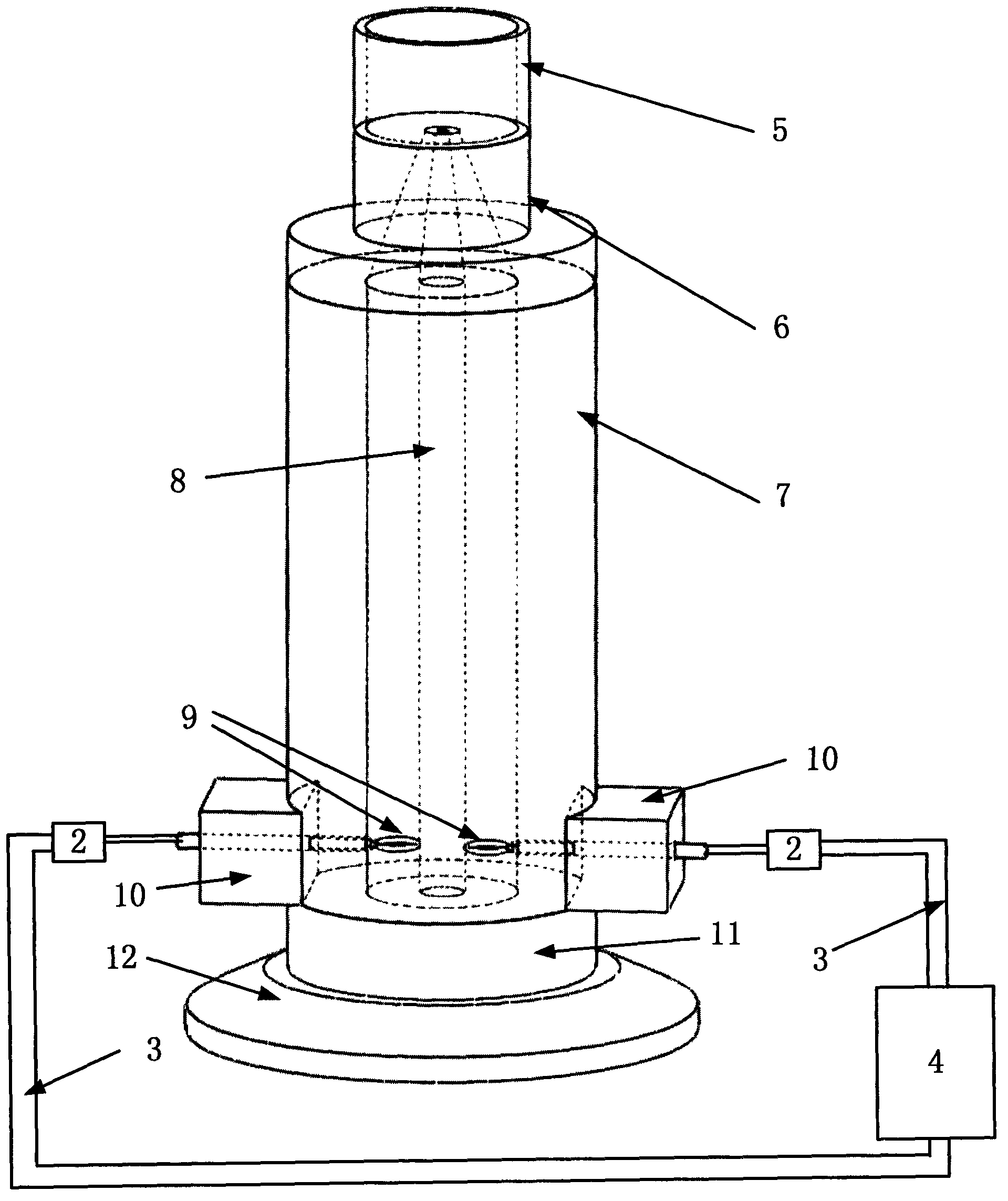

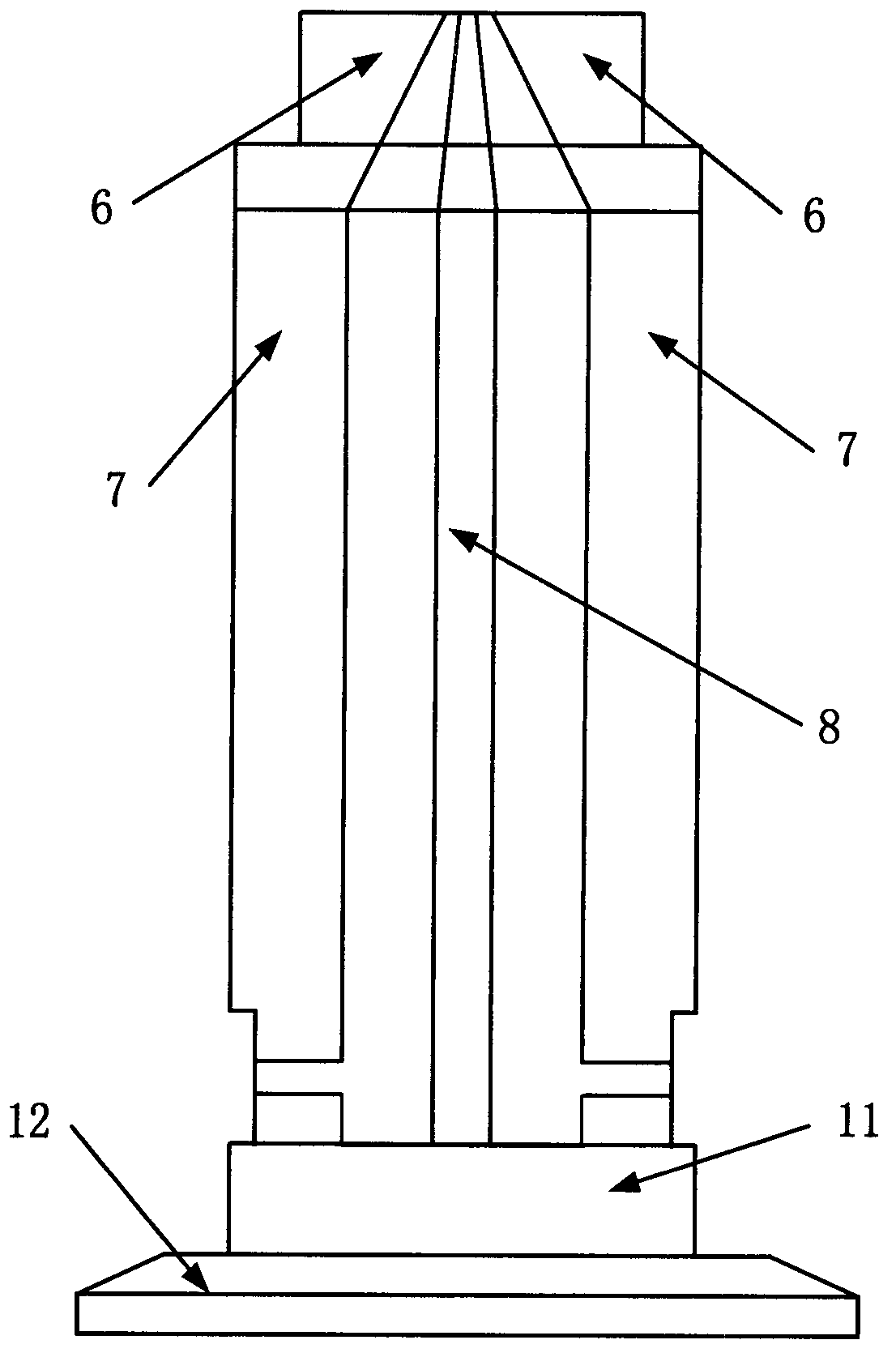

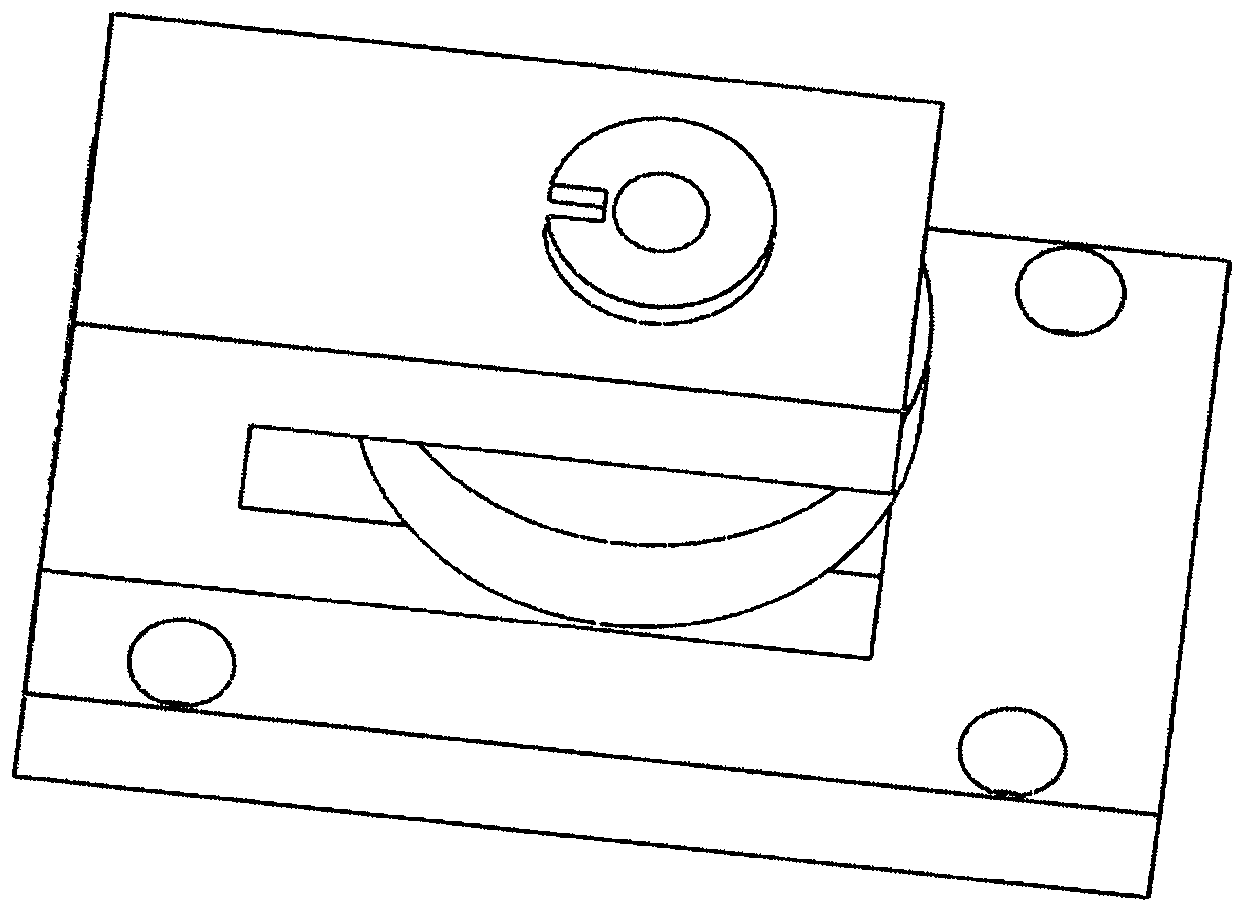

[0021] Place the wine glass furniture (5) over the Open Coaxial Resonator (1), then insert the probe into the cavity and connect it to the SMA to other coaxial connector converter (2) , the cable (3), and the vector network analyzer (4) are connected together to realize the link of the whole system.

[0022] The specific steps for testing the electromagnetic parameters of microwave materials by using the Open Coaxial Resonator are:

[0023] Step 1: Select the test frequency range, adjust the length of the probe into the cavity through the coupling regulator to maximize the quality factor of the system at the resonant frequency point, and record the system resonant frequency f within the test range of the system loaded with any sample 0 And the quality factor Q of the corresponding frequency point 0 ;

[0024] Step 2: Put an appropriate amount of material to be tested into the wine glass furniture with a thickness of d, and test to obtain the resonant frequency f of the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com