Simulation training platform system for fault detection and maintenance simulation of numerically-controlled machine tool

A technology for CNC machine tools and fault detection, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of large equipment investment, poor training effect, single system, etc., and achieve fast update, low cost, and convenient teaching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The technical solution of the present invention will be explained in detail below in conjunction with the accompanying drawings.

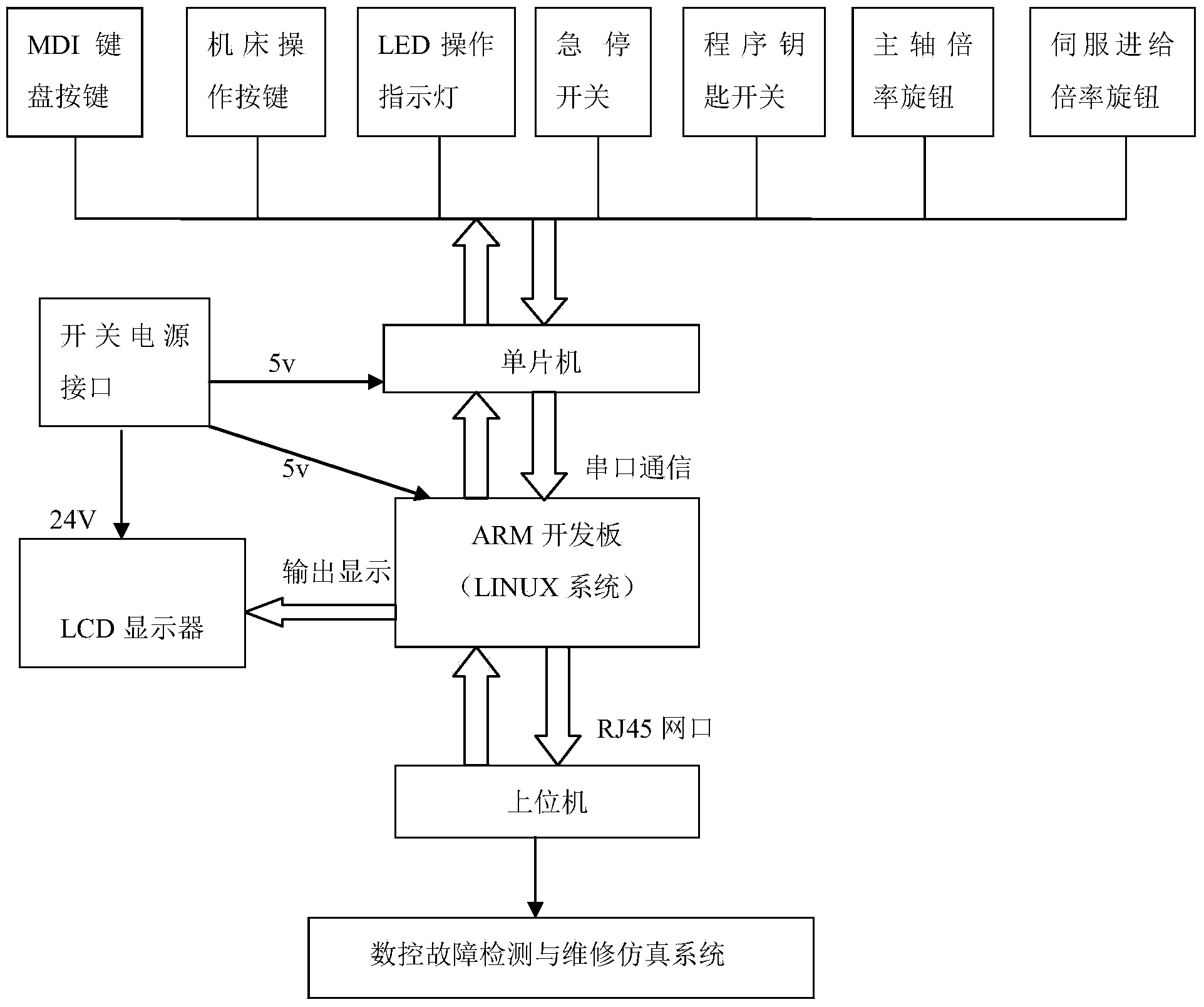

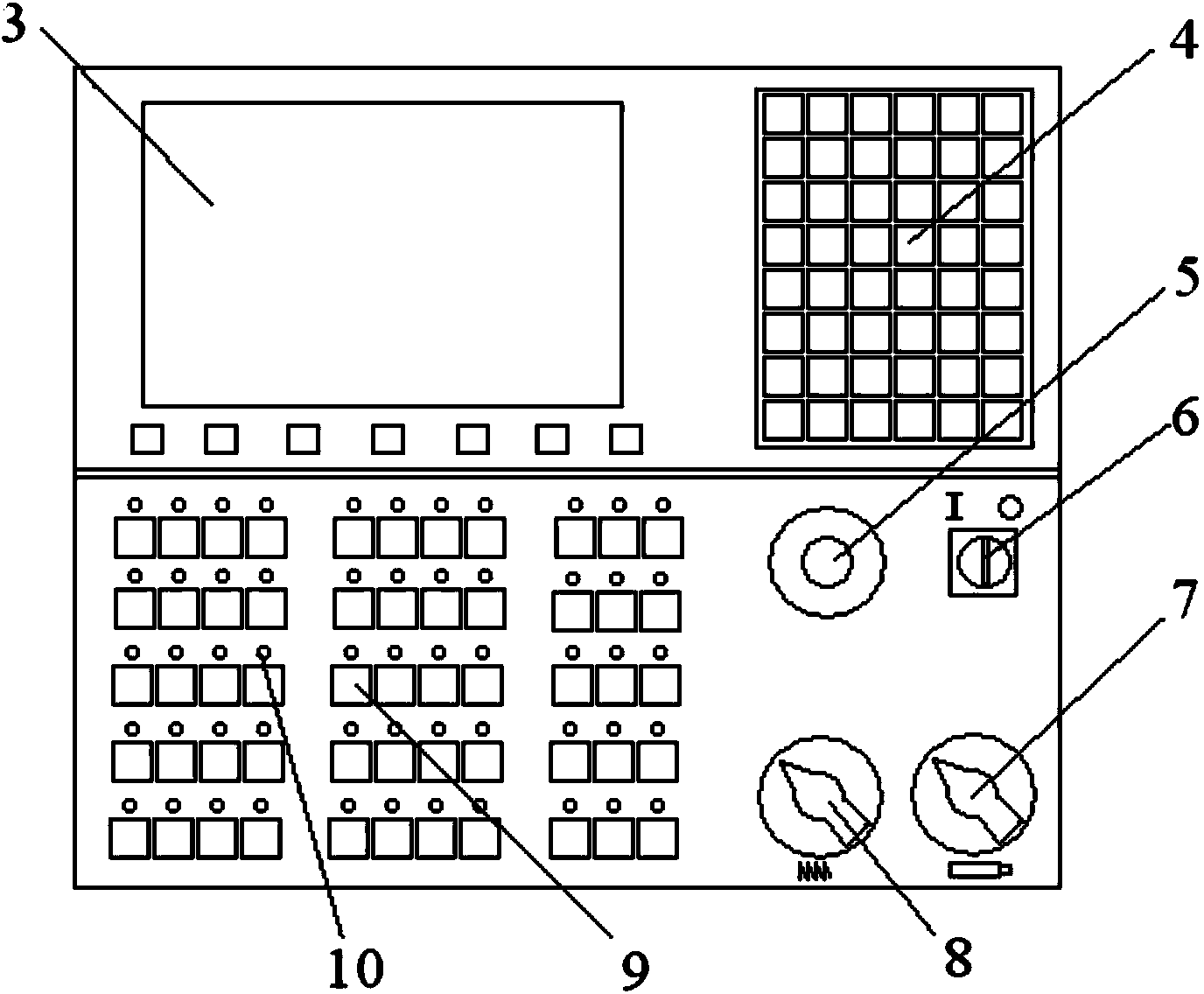

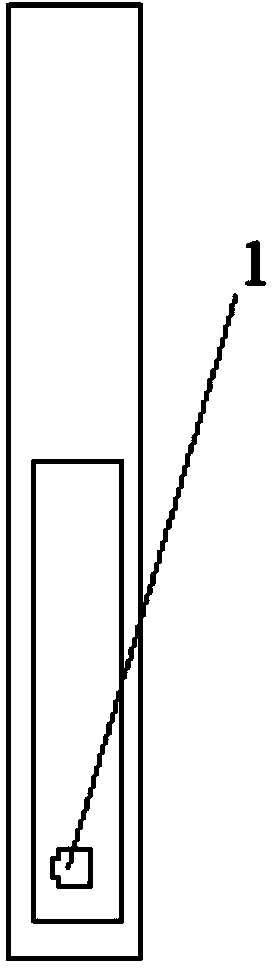

[0043] participate figure 1 A numerical control machine tool fault detection and maintenance simulation training platform system is composed of a numerical control display and operation platform, a host computer and a set of numerical control fault detection and maintenance simulation system installed in the host computer. refer to Figure 2 to Figure 4 , the CNC display and operation platform is a box structure, and the data transmission RJ45 interface 1, switching power supply interface 2, LCD display 3, MDI keyboard 4, emergency stop switch 5, program key switch 6, and spindle are installed on the CNC display and operation platform. Magnification knob 7, servo feed magnification knob 8, standard machine tool operation button panel 9, LED operation indicator light 10; among them, the data transmission RJ451 interface is located at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com