Electrochemical capacitor and manufacturing method of electrochemical capacitor

A capacitor and electrochemical technology, which is applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of poor energy storage effect of batteries, and achieve the effects of high capacitance, high energy density and power density, and low self-discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The realization of the objectives, functional characteristics and advantages of the present invention will be further described below in conjunction with embodiments and with reference to the drawings.

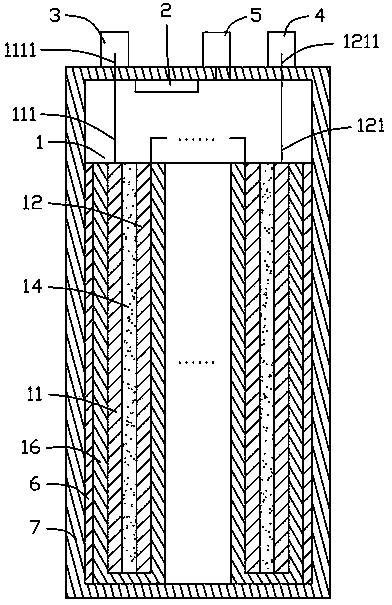

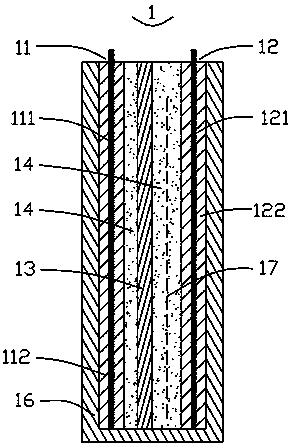

[0023] Reference Figure 1-3 As shown, the electrochemical capacitor includes a plurality of single capacitors 1, an equalizer 2, a positive screw 3, a negative screw 4, a safety valve 5, an elastic pad 6 and a capacitor case 7. The single capacitors 1 are placed side by side in the capacitor case 7. The individual capacitors 1 are connected in series in order. In other embodiments, multiple individual capacitors can be connected in parallel or mixed in series and parallel.

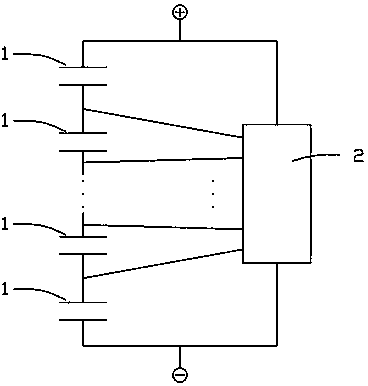

[0024] Both the positive and negative poles of the single capacitor 1 are connected to the corresponding terminals of the equalizer 2, such as image 3 As shown, the charging and discharging current of each single capacitor is ensured to be balanced, the damage caused by the uneven output voltage of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com