Composite negative electrode, preparation method of negative electrode and lithium-sulfur secondary battery with negative electrode

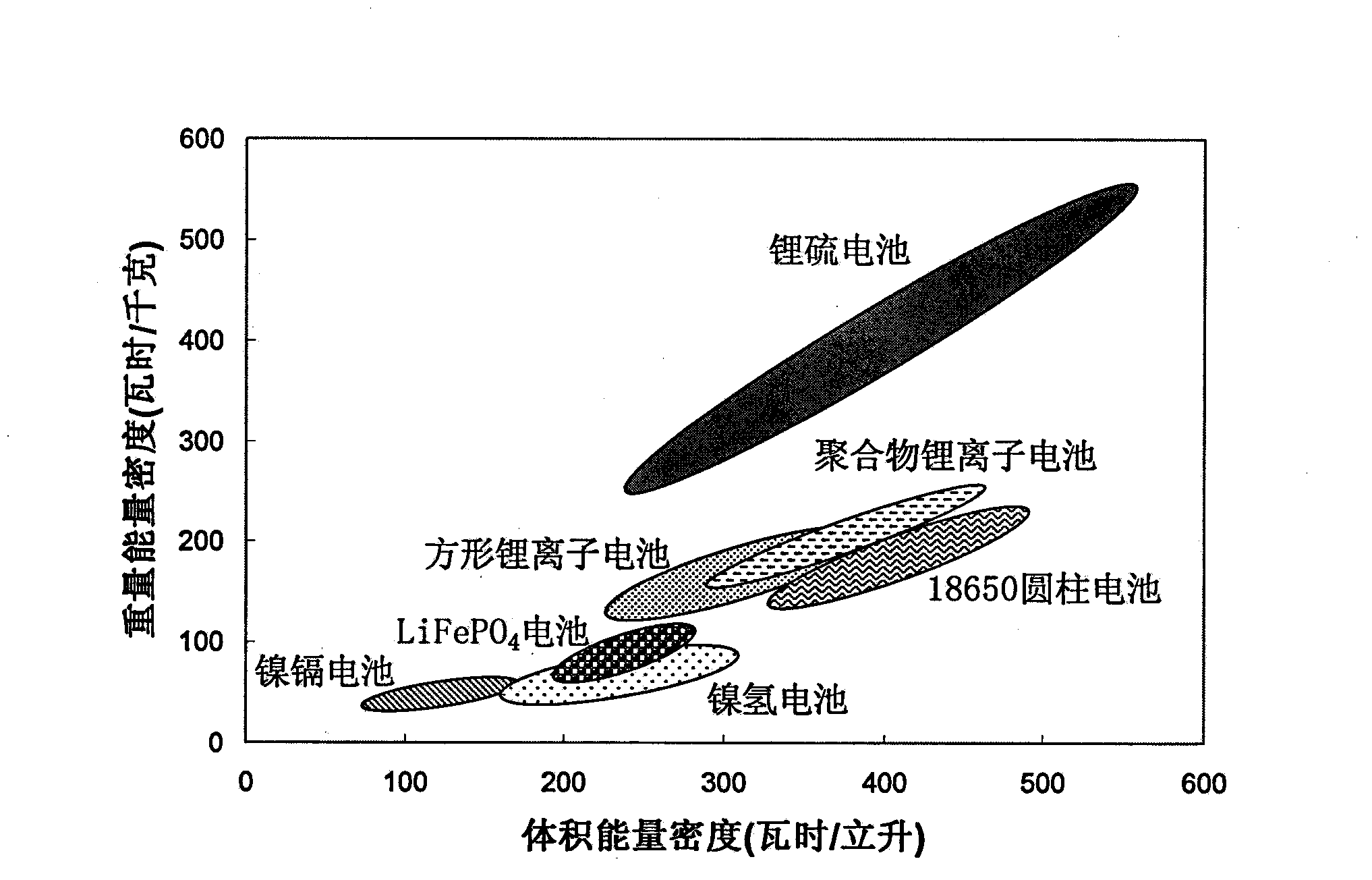

A lithium-sulfur secondary battery and battery negative electrode technology, which is applied in the manufacture of battery electrodes, lithium batteries, electrolyte batteries, etc., can solve the problems of sacrificing high-power discharge of secondary batteries, increasing battery internal resistance, etc., and achieve long-lasting user experience, The effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

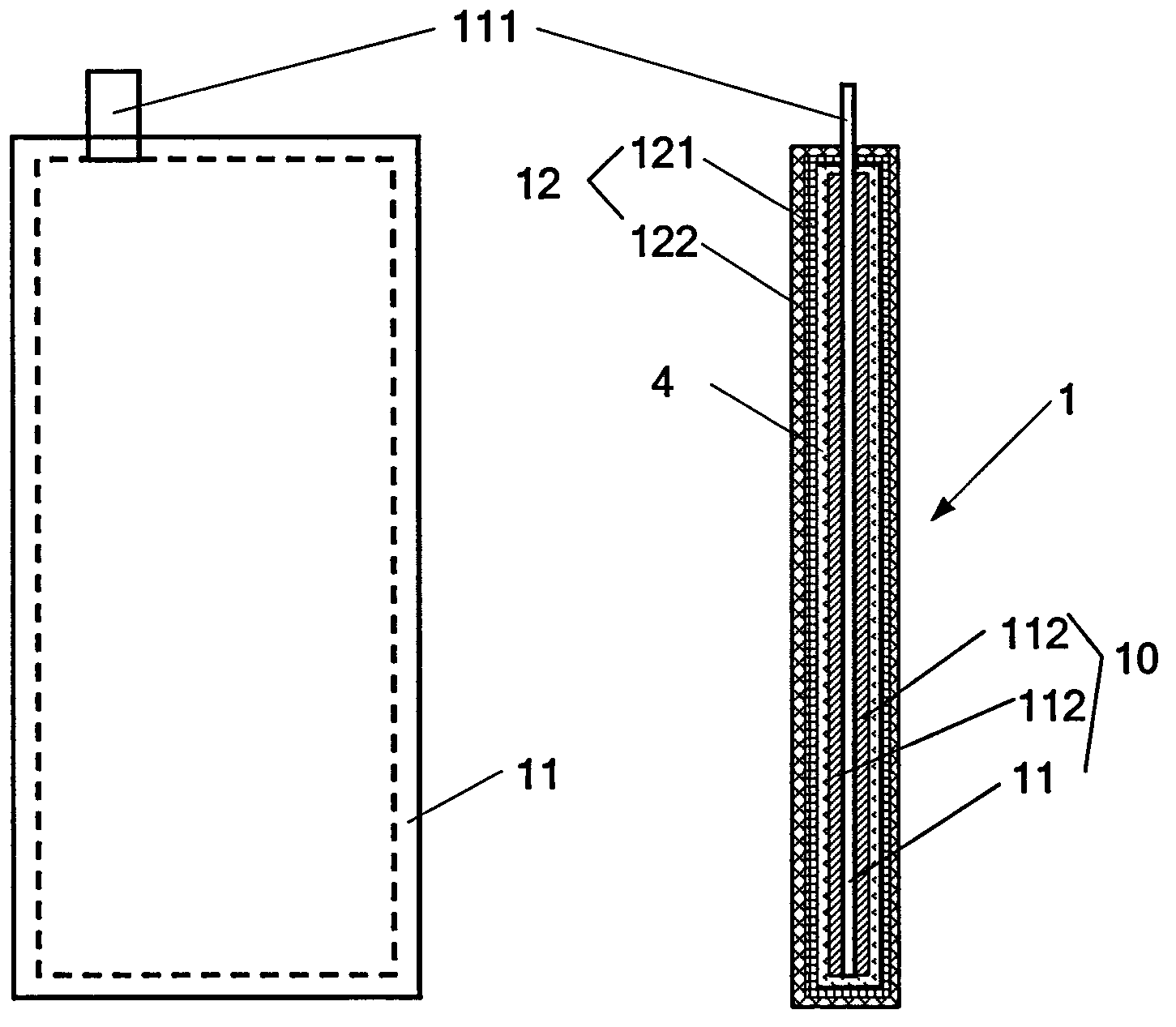

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

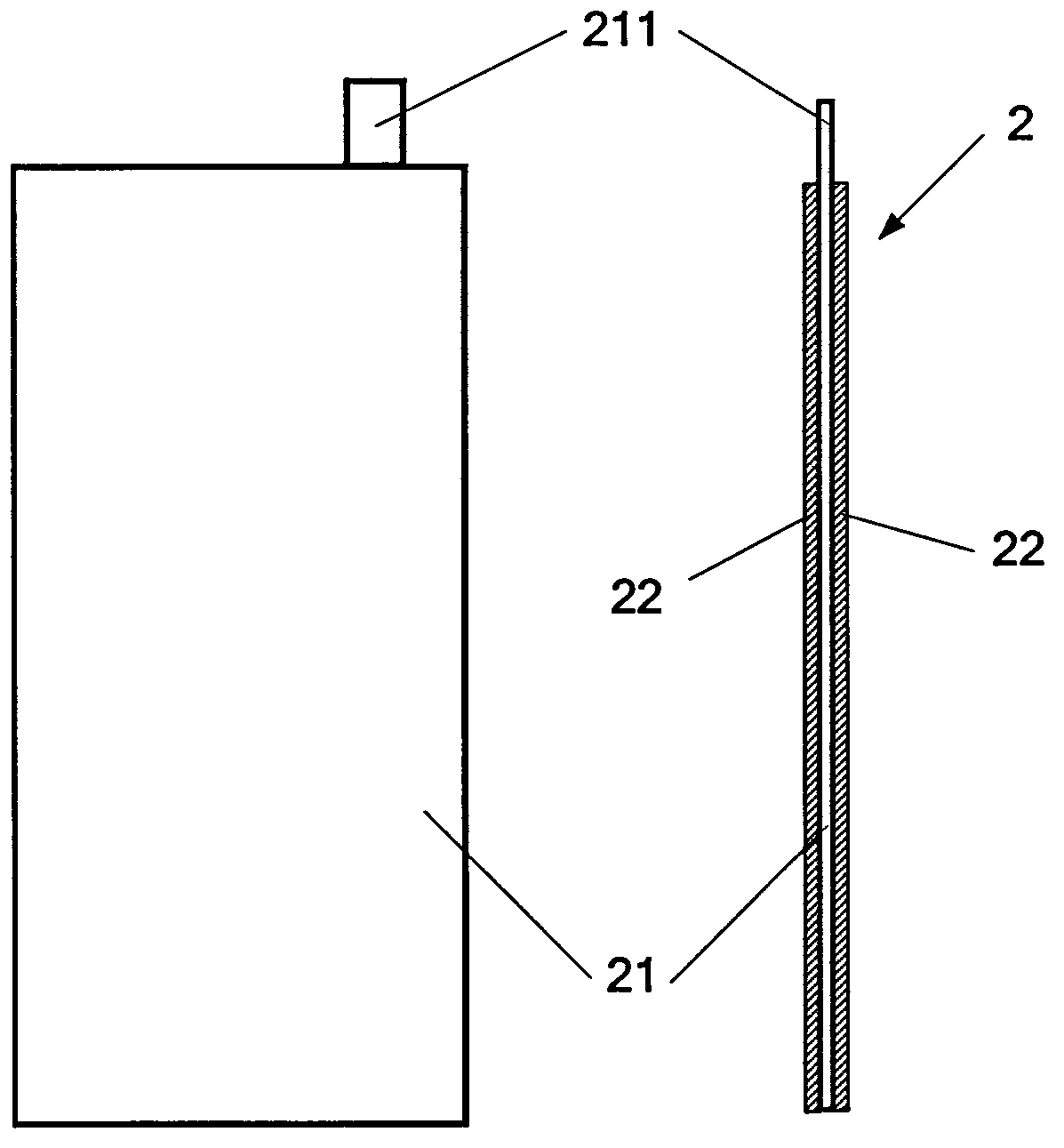

[0041] combine Figure 2 to Figure 4 , the composite negative electrode according to the embodiment of the present invention includes: copper foil 11 and solid lithium ion conductive separator belt 12 . Of course, the copper foil 11 can also be replaced by other metals, and no example is given here.

[0042] Among them, one end of the copper foil 11 is provided with a tab 111 for conducting current. The overall shape of the tab 111 and the copper foil 11 is similar to a kitchen knife, and the tab 111 is similar to a knife handle. Usually, the tab 111 and the copper foil 11 are an integral structure. Formed, or integrally formed by punching, casting, etc.

[0043] Moreover, at least one side of the copper foil 11 is closely provided with a metal lithium foil 112 or an alloy lithium foil as the negative electrode 10 of the battery, except that the tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Pore diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com