Switching-loss-free full-bridge non-isolated photovoltaic grid-connected inverter and on-off control timing sequence

A non-isolated, non-switching technology, applied in photovoltaic power generation, AC power input conversion to DC power output, output power conversion devices, etc., can solve problems such as diode reverse recovery, to eliminate leakage current and reverse recovery problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

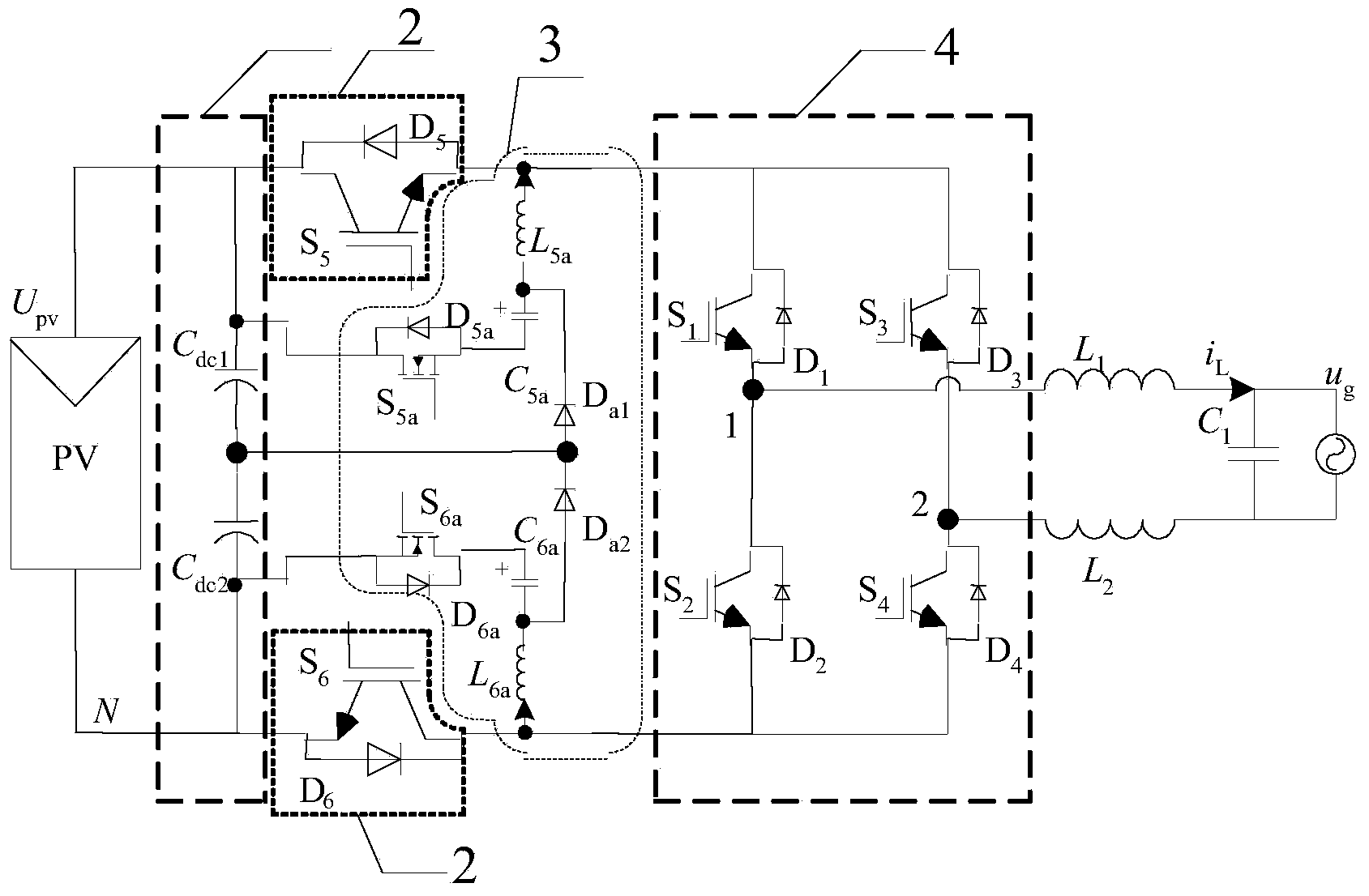

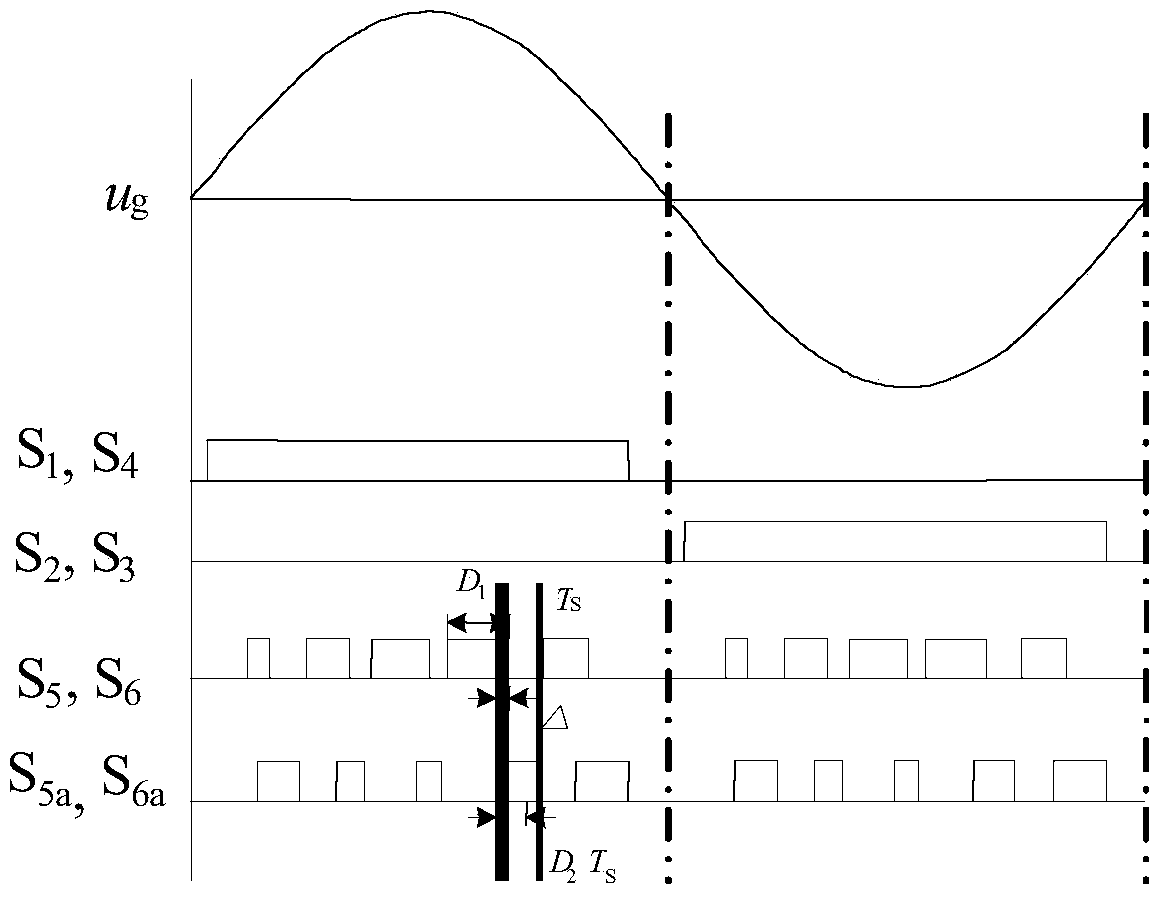

[0034] Such as figure 2 As shown, the configuration of the main circuit in Embodiment 1 of the present invention consists of the first voltage dividing capacitor C dc1 and the second divider capacitor C dc2 Form the basic unit 1;

[0035] By the fifth power switch tube S 5 and the fifth power diode D 5 Parallel combination, the sixth power switch tube S 6 and the sixth power diode D 6 Parallel combination forms the basic unit 2;

[0036] By the fifth auxiliary power switch S 5a and the fifth auxiliary power diode D 5a Parallel combination, the fifth auxiliary resonant inductor L 5a , the fifth auxiliary resonant capacitor C 5a , the sixth auxiliary power switch tube S 6a and the sixth auxiliary power diode D 6a Parallel combination, the sixth auxiliary resonant inductor L 6a , the sixth auxiliary resonant capacitor C 6a and the first auxiliary freewheeling clamp power diode D a1 , The second auxiliary freewheeling clamp power diode D a2 Form the basic unit 3; ...

Embodiment 2

[0044] Such as Figure 7 As shown, the main circuit of the second embodiment of the present invention consists of a DC filter capacitor C dc Composing the basic unit 71;

[0045] By the fifth power switch tube S 5 and the fifth power diode D 5 Parallel combination, the sixth power switch tube S 6 and the sixth power diode D 6 Parallel combination forms the basic unit 72;

[0046] By the fifth auxiliary power switch S 5a and the fifth auxiliary power diode D 5a Parallel combination, the fifth auxiliary resonant inductor L 5a , the fifth auxiliary resonant capacitor C 5a , the sixth auxiliary power switch tube S 6a and the sixth auxiliary power diode D 6a Parallel combination, the sixth auxiliary resonant inductor L 6a , the sixth auxiliary resonant capacitor C 6a and the first auxiliary freewheeling power diode D a1 Composing the basic unit 73;

[0047] By the first power switch tube S 1 and the first power diode D 1 Parallel combination, the second power switch...

Embodiment 3

[0051] Such as Figure 8 As shown, the main circuit of the third embodiment of the present invention consists of the first voltage dividing capacitor C dc1 and the second divider capacitor C dc2 Composing the basic unit 81;

[0052] By the fifth power switch tube S 5 and the fifth power diode D 5 Parallel combination, the sixth power switch tube S 6 and the sixth power diode D 6 Parallel combination forms basic unit 82;

[0053] By the fifth auxiliary power switch S 5a and the fifth auxiliary power diode D 5a Parallel combination, the fifth auxiliary resonant inductor L 5a , the fifth auxiliary resonant capacitor C 5a , the sixth auxiliary power switch tube S 6a and the sixth auxiliary power diode D 6a Parallel combination, the sixth auxiliary resonant inductor L 6a , the sixth auxiliary resonant capacitor C 6a and the first auxiliary freewheeling power diode D a1 Composing the basic unit 83;

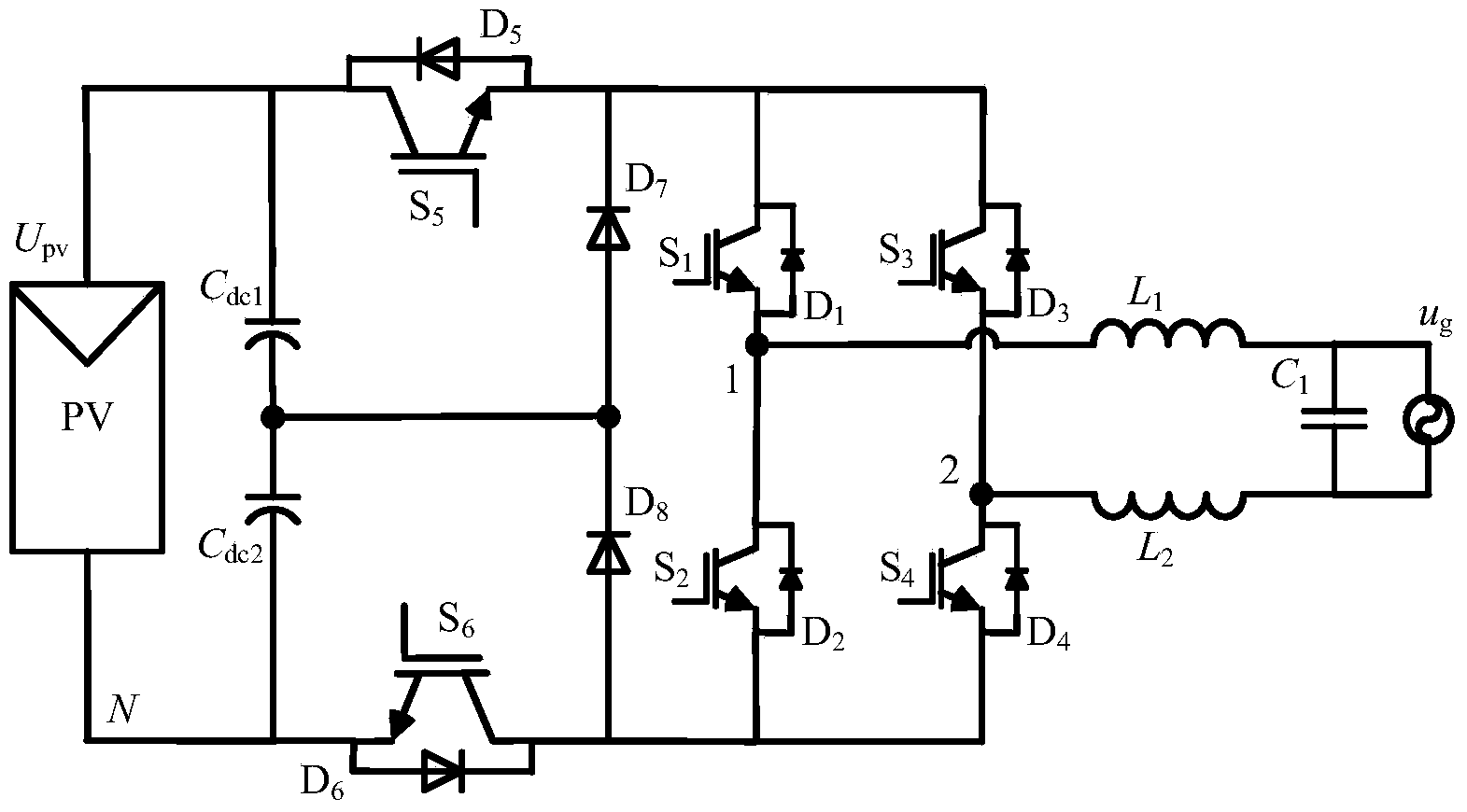

[0054] clamped by the seventh power diode D 7 and the eighth clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com