Semiconductor device and method of manufacture thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, identification devices, etc., can solve the problems of reduced aperture ratio, increased power consumption, and increased backlight brightness, achieving high aperture ratio, sufficient The effect of reliability, ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, a semiconductor device according to an embodiment of the present invention will be described with reference to the drawings. The semiconductor device of this embodiment includes a thin film transistor (oxide semiconductor TFT) having an active layer made of an oxide semiconductor. In addition, the semiconductor device according to the present embodiment may broadly include active matrix substrates, various display devices, electronic equipment, and the like as long as it includes an oxide semiconductor TFT.

[0048] Here, a TFT substrate including an oxide semiconductor TFT used in a liquid crystal display device will be described as an example.

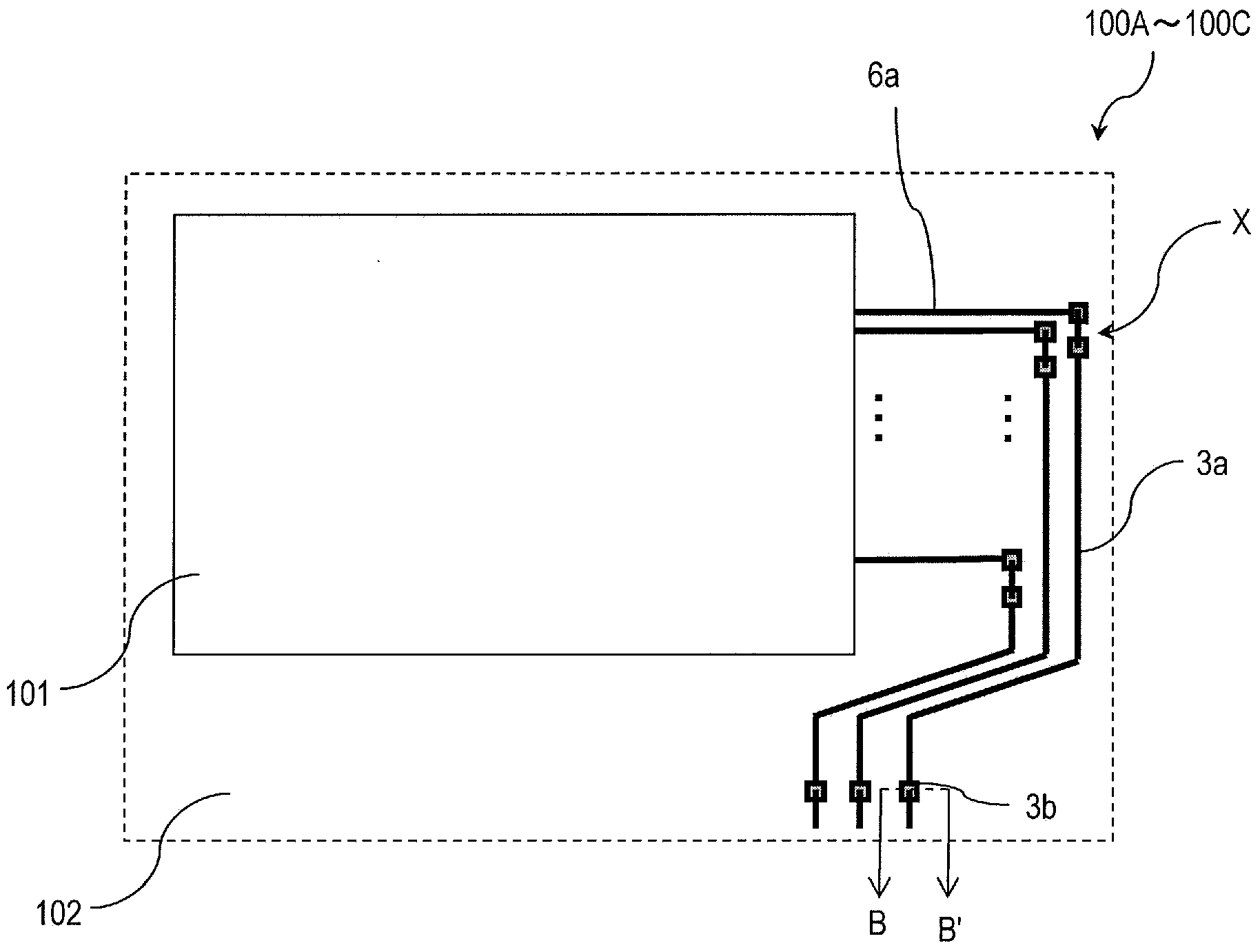

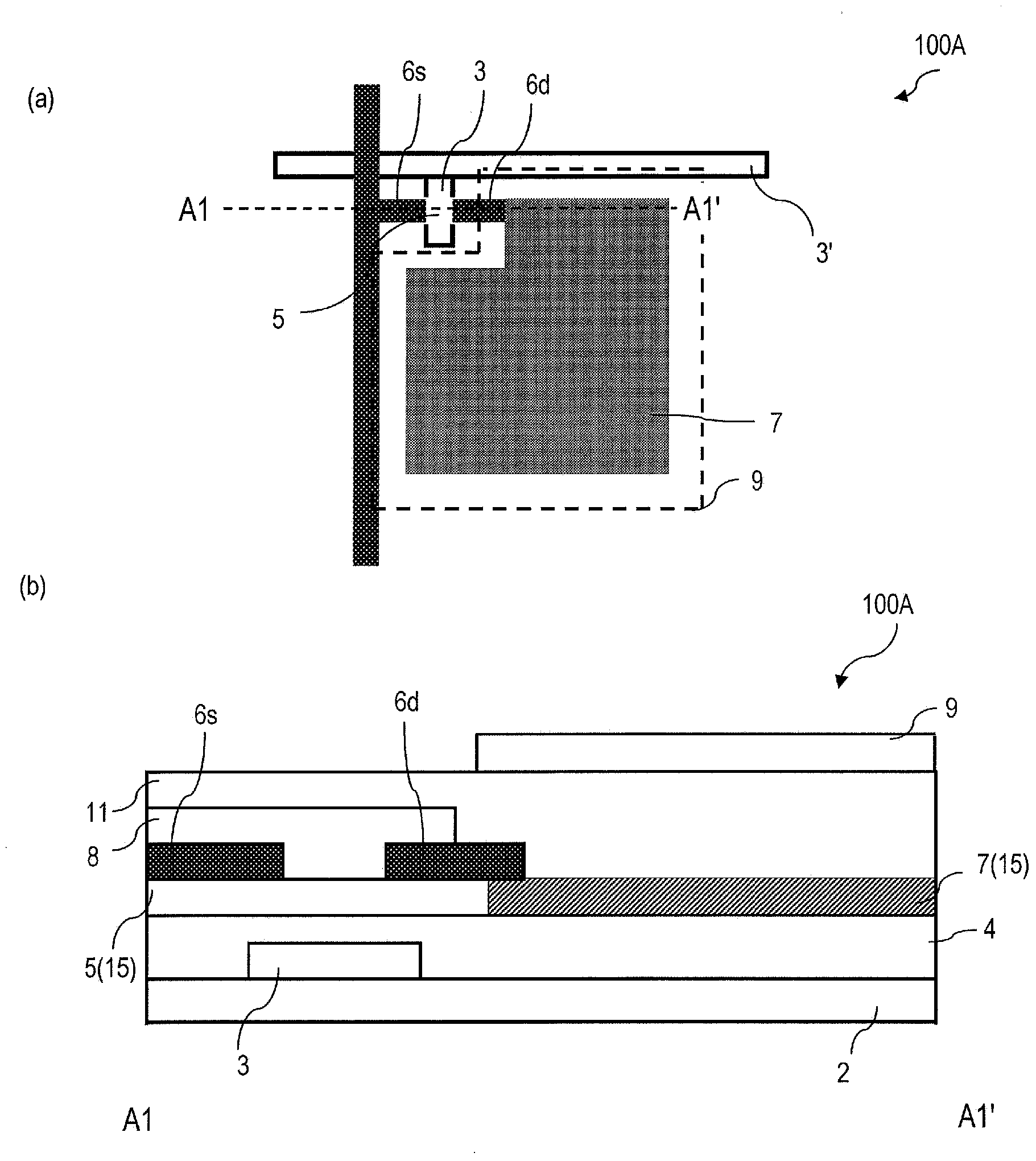

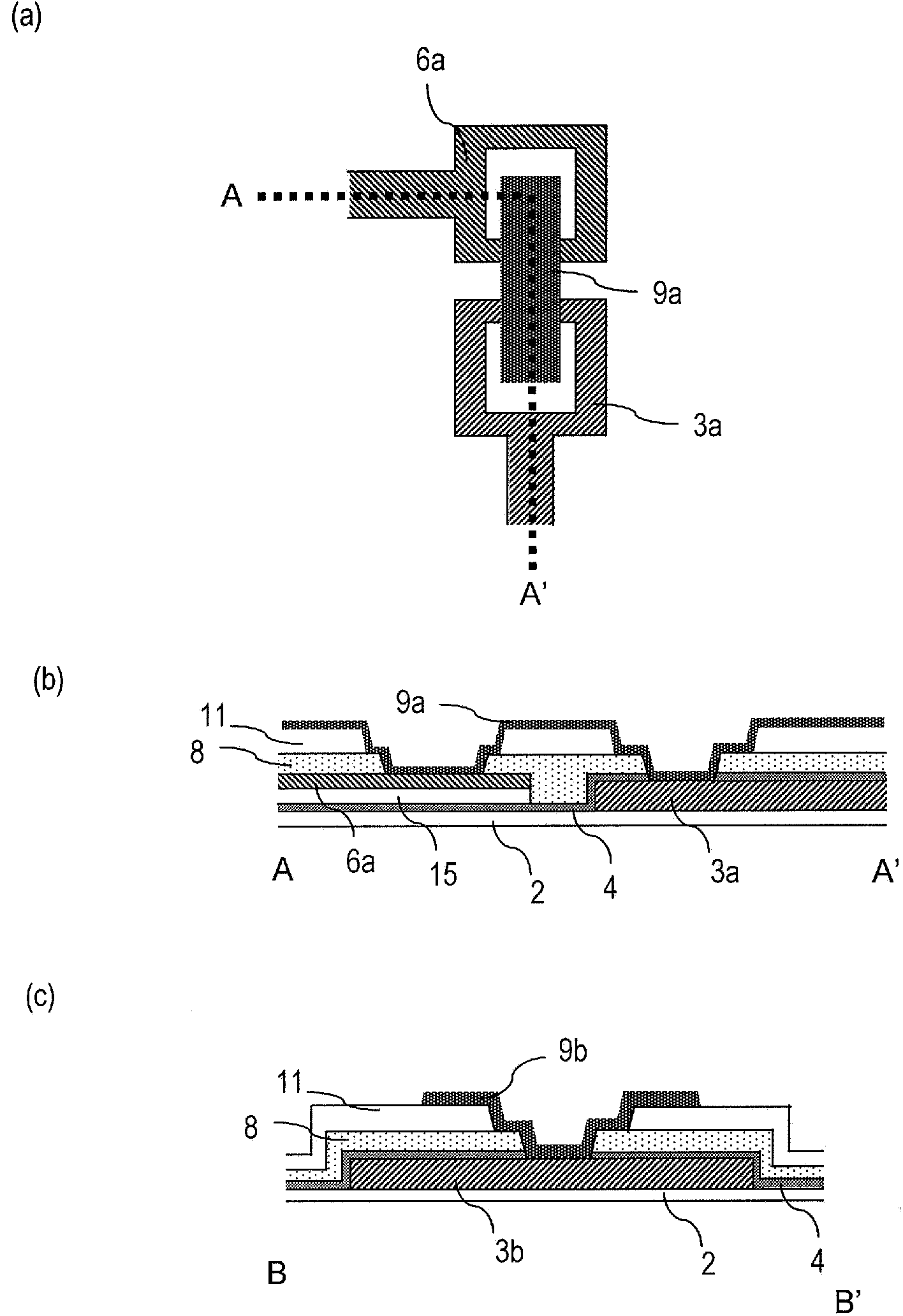

[0049] figure 1 It is a schematic plan view of TFT substrate 100A of this embodiment. figure 2 (a) is a schematic plan view of one pixel in the TFT substrate 100A, figure 2 (b) is along figure 2 (a) Schematic cross-sectional view of A1-A1' line. image 3 (a) is figure 1 A schematic enlarged plan view of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com