A microfluidic chip based on optical detection and its preparation method

A microfluidic chip and optical detection technology, applied in the fields of medical diagnosis, bioengineering, and biochemical analysis, can solve the problems of increasing process complexity, reducing device stability, deformation, etc., to eliminate channel surface roughness, improve detection accuracy, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

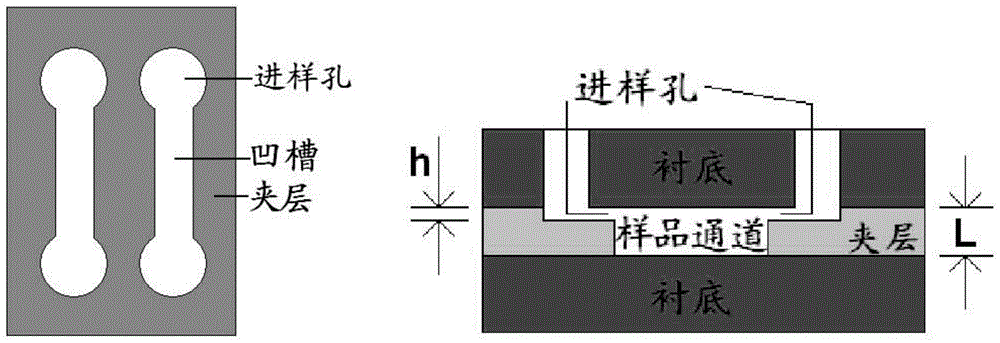

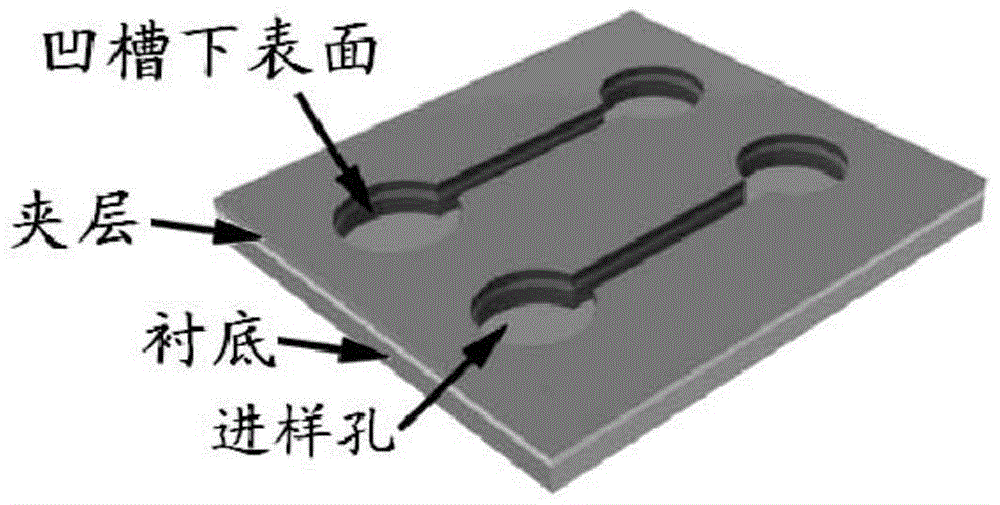

[0030] refer to Figure 1 to Figure 4 , the present invention provides a microfluidic chip based on optical detection, including an upper substrate layer, a lower substrate layer, and an interlayer all made of glass, the interlayer is located in the middle of the two substrate layers, and the interlayer is provided with a sample channel And the sampling hole, the sample channel is composed of the groove structure penetrated in the interlayer and the substrate surface; the corrosion depth of the interlayer sampling hole in this embodiment is equal to the thickness of the interlayer.

[0031] The present invention also provides a method for preparing a microfluidic chip based on optical detection, which mainly includes the following steps:

[0032] In the first step, utilize an etching process to prepare groove structures and injection holes on the glass interlayer. The etching process in this embodiment is chemical etching, wherein the grooves penetrate the glass interlayer (su...

Embodiment 2

[0035] refer to Figure 1 to Figure 4 , the present invention provides a microfluidic chip based on optical detection, comprising an interlayer made of glass, an upper substrate layer and a lower substrate layer made of silicon, the interlayer is located in the middle of the two substrate layers, and the interlayer is set There are sample channel and sampling hole, and described sample channel is made of the groove structure that penetrates in the interlayer and the substrate surface; The corrosion depth of the interlayer sampling hole described in the present embodiment is equal to 0.9 times of the thickness of the interlayer; The substrate is provided with a sampling hole, and the substrate sampling hole is connected to the interlayer sampling hole;

[0036] The present invention also provides a method for preparing a microfluidic chip based on optical detection, which mainly includes the following steps:

[0037] In the first step, the groove structure and the sampling hol...

Embodiment 3

[0040] refer to Figure 1 to Figure 4 , the present invention provides a microfluidic chip based on optical detection, comprising an interlayer made of silicon, an upper substrate layer and a lower substrate layer made of glass, the interlayer is located in the middle of the two substrate layers, and the interlayer is set There are sample channel and sampling hole, and described sample channel is made of the groove structure that penetrates in the interlayer and the substrate surface; The corrosion depth of the interlayer sampling hole described in the present embodiment is equal to 0.5 times of the thickness of interlayer; The substrate is provided with a sampling hole, and the substrate sampling hole is connected to the interlayer sampling hole; the glass substrate is coated with Si / SiO 2 film.

[0041] The present invention also provides a method for preparing a microfluidic chip based on optical detection, which mainly includes the following steps:

[0042] The first ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com