High-strength intrinsic safety instrument cable

A high-strength technology for instrument cables, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as prone to failure and poor strength, and achieve the effects of improving strength, meeting multi-corrosion, and improving shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

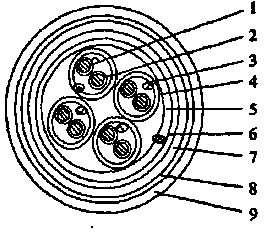

[0014] Such as figure 1 As shown, a high-strength intrinsically safe instrument cable includes a cabled core, the cabled core is wrapped with a polyester film layer, the polyester film is wrapped with an aluminum foil polyester composite tape, and the aluminum foil polyester A grounding drain wire twisted by a tinned copper wire is clamped inside the composite tape, and the drain wire is in contact with the aluminum layer of the aluminum foil polyester composite tape. A braided layer of tinned copper wire is arranged outside the lining layer, and a composite sheath is arranged outside the braided shielding layer, and two high-strength steel wires parallel to each other and arranged along the longitudinal direction of the cable are arranged at the center of the wall thickness of the composite sheath. Among them, the four groups of cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com