Preparation method of shortening without trans-fatty acids

A shortening and fatty acid technology, applied in the field of shortening preparation, can solve the problems of underutilization, waste of resources, etc., achieve good mouth melting, avoid waste, and ensure the effects of tissue structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

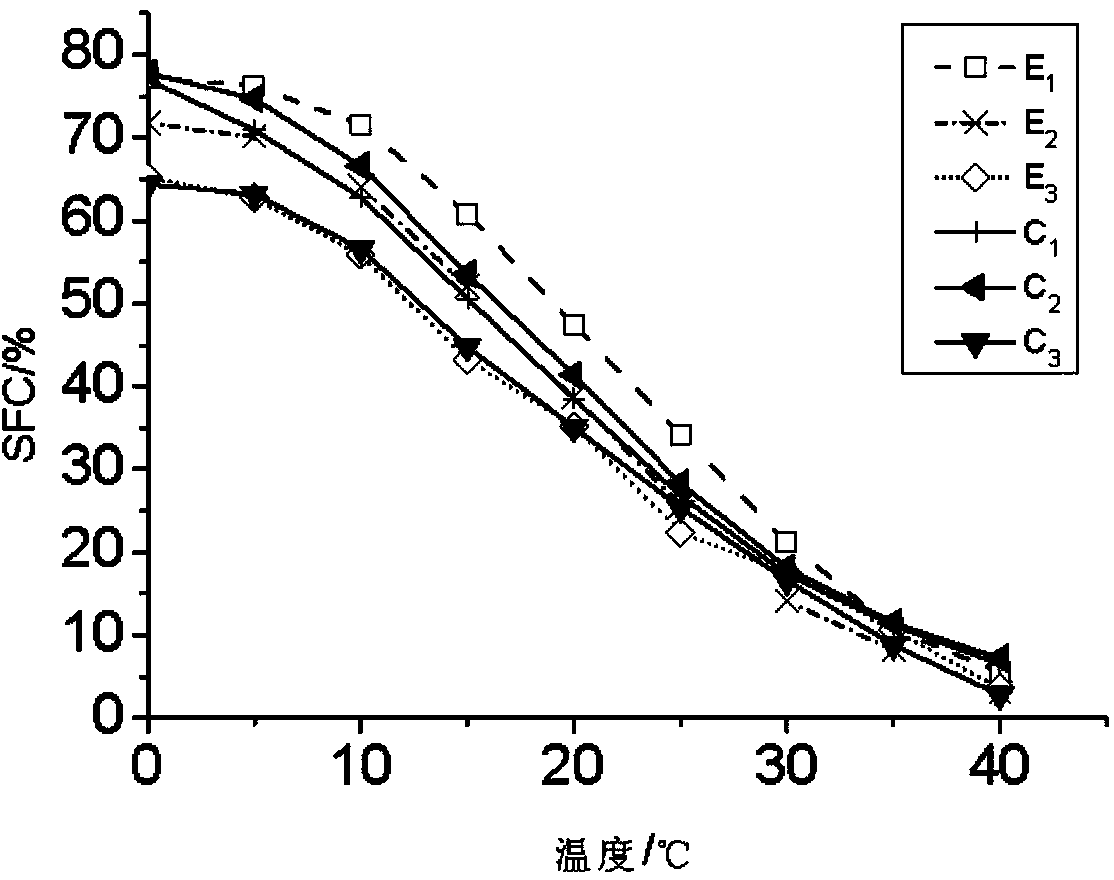

[0030] After melting rice bran solid fat, fully hydrogenated soybean oil and coconut oil, mix according to the ratio of 41.6% by mass: 41.6%: 16.8%; add 5% by mass of immobilized lipase Lipozyme RM IM catalytic system to perform transesterification Reaction, temperature 60°C, reaction time 5h. The melting point of the system after the reaction is close to 40°C. It is measured that the content of oryzanol is 504.1mg / 100g, the content of medium-chain triglycerides is about 9.61%, and the content of total sterols is 324.4mg / 100g. The SFC curve is similar to that of commercially available anhydrous ghee similar, such as figure 1 shown.

Embodiment 2

[0032] After melting rice bran solid fat, fully hydrogenated soybean oil and coconut oil, mix according to the ratio of 50.0% by mass: 33.3%: 16.8%; add 6% by mass of immobilized lipase Lipozyme RM IM catalytic system to carry out transesterification Reaction, temperature 65 ℃, reaction time 6h. After the reaction, the melting point of the system is close to 40°C, the oryzanol content is 634.0mg / 100g, the medium carbon chain triglyceride content is about 6.44%, the total sterol content is 352.9mg / 100g, and the SFC curve is similar to that of commercially available anhydrous ghee, such as figure 1 shown.

Embodiment 3

[0034] After melting rice bran solid fat, fully hydrogenated soybean oil and coconut oil, mix them according to the ratio of 63.6% by mass: 27.3%: 9.1% by mass; add 8% by mass of immobilized lipase Lipozyme RM IM catalyst system for transesterification Reaction, temperature 70°C, reaction time 7h. After the reaction, the melting point of the system is close to 40°C, the oryzanol content is 882.6mg / 100g, the medium carbon chain triglyceride content is about 5.41%, the total sterol content is 439.6mg / 100g, and the SFC curve is similar to that of commercially available anhydrous ghee, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com