A water washing deep dust removal device

A technology of water washing dust removal and dust removal device, which is applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents. It can solve the problems of large floor area, increased dust, and the inability to achieve low dust concentration standards at the outlet of flue gas pipes. , to achieve the effect of reducing the amount of dust carried

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

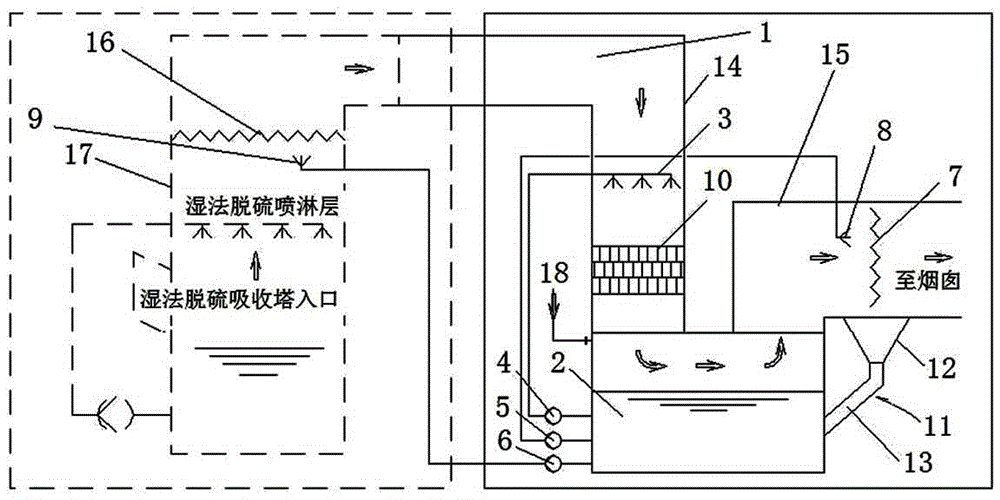

[0043] Thermal power plants and other enterprises need to reduce the dust content in the flue gas in order to meet the increasing flue gas emission standards. The usual method is to install a dust collector (electric dust collector or bag dust collector) in front of the induced draft fan or use wet desulfurization The downstream installation of wet electrostatic precipitator. The technical defect of the existing technology is that it is difficult to solve the technical problem of dust reaching the standard or even ultra-low emission, and the investment cost of the existing device or dust removal process is high, and the floor area is large. In view of the above problems, this embodiment designs a new type of water washing deep dust removal device, which is installed downstream of the demister of the wet desulfurization absorption tower, and the flue gas enters the flue 1 of the washing section from the entrance of the wet desulfurization absorption tower 17, Wash the flue gas ...

Embodiment 2

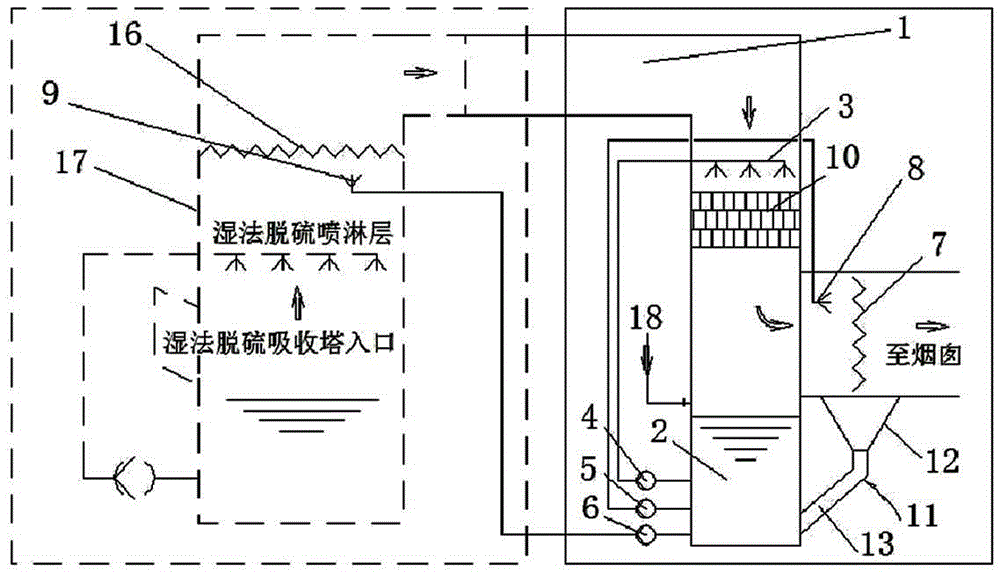

[0056] Such as figure 2 As shown, the water washing deep dust removal device described in this embodiment is basically similar to that of Embodiment 1, and the main components are still the washing section flue 1, the circulating pool 2, the water washing spray layer 3, the water washing dust removal circulating pump 4, the water washing Dust and mist eliminator flushing water pump 5, absorption tower mist eliminator flushing water pump 6, water washing dust and mist eliminator 7, first flushing nozzle 8 and second flushing nozzle 9, etc. also, figure 2 It is shown that the deep water washing dedusting device described in this embodiment also includes a process water supply interface 18, a packing layer 10 and a washing water collecting device 11 for water washing dedusting and mist eliminator.

[0057]The difference between this embodiment and the deep water washing dedusting device described in Embodiment 1 is that the flue 1 in the washing section is an integral flue. T...

Embodiment 3

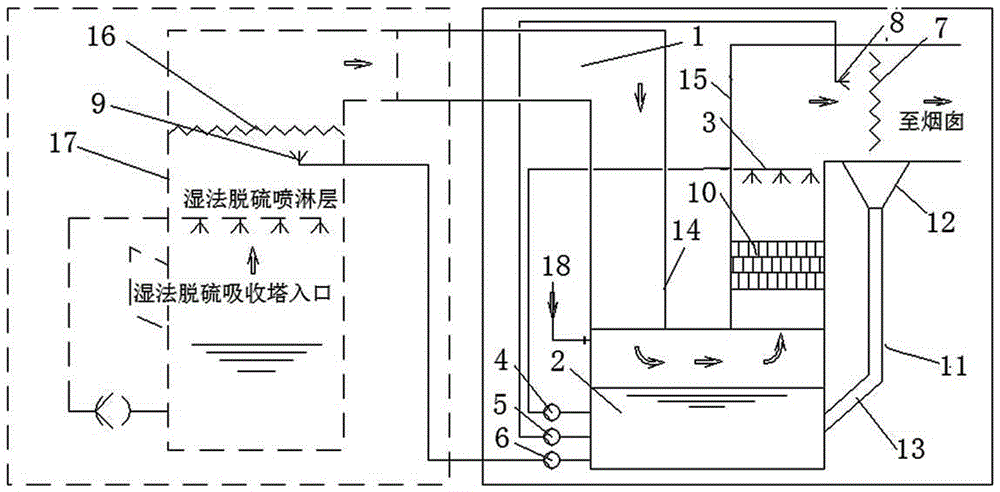

[0061] The water washing deep dust removal device described in this embodiment is another preferred solution of the present invention, such as image 3 As shown, it mainly includes washing section flue 1, circulating pool 2, water washing spray layer 3, water washing dust removal circulation pump 4, water washing dust removal mist eliminator flushing water pump 5, absorption tower mist eliminator flushing water pump 6, water washing dust removal mist eliminator 7. The first flushing nozzle 8 and the second flushing nozzle 9, etc. also, image 3 It is shown that the deep water washing dedusting device described in this embodiment also includes a process water supply interface 18, a packing layer 10 and a washing water collecting device 11 for water washing dedusting and mist eliminator.

[0062] The design of the washing section flue 1 of the water-washing depth dust removal device described in this embodiment is the same as that of embodiment 1, that is, the washing section f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com