Storage-reduction catalyst and preparation method thereof

A catalyst and catalyst quality technology, applied in the storage-reduction field of nitrogen oxides, can solve the problems of low removal rate of nitrogen oxides, weakening catalytic activity of precious metals, etc., and achieve the effect of improving efficiency, improving removal rate, and improving overall efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention also provides a catalyst preparation method, which can prepare the above-mentioned storage-reduction catalyst. The preparation method includes the following steps: mechanically grinding or mechanically stirring the first catalyst and the second catalyst for 30 minutes to 60 minutes to obtain the storage-reduction catalyst. catalyst.

[0037] It should be noted that the first catalyst is a catalyst supported solely by the above-mentioned noble metal, and the second catalyst is a catalyst jointly supported by the above-mentioned noble metal and storage components; and in the process of mechanical grinding or mechanical stirring, the first catalyst will not be destroyed and the composition of the second catalyst.

[0038] As an implementation manner, the first catalyst and the second catalyst are synthesized by an existing chemical method, such as an impregnation method.

[0039] The storage-reduction catalyst of the invention has a simple structure,...

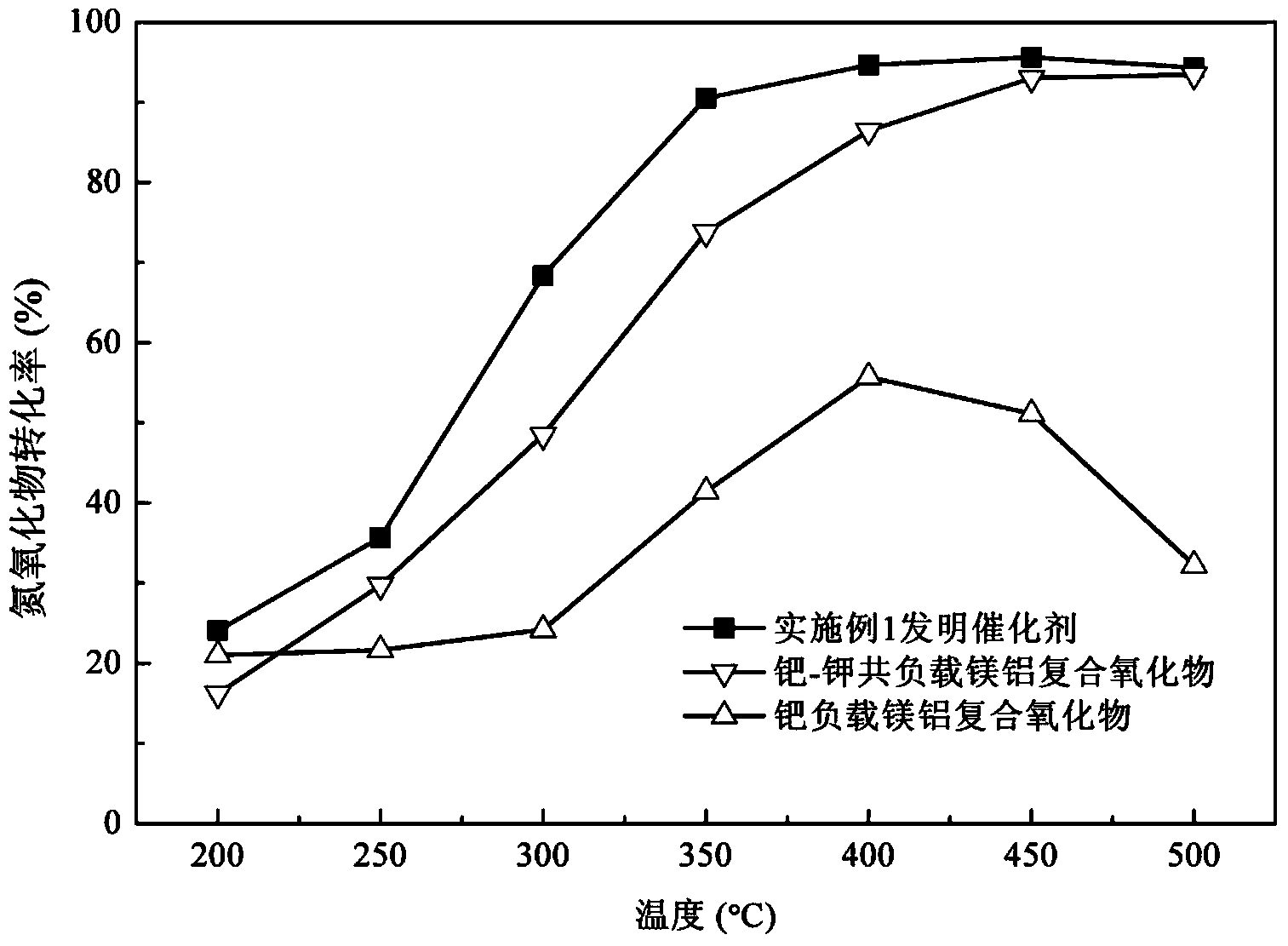

Embodiment 1

[0042] The magnesium-aluminum composite oxide supported by palladium (the mass fraction of palladium is 1%) and the magnesium-aluminum composite oxide supported by palladium-potassium (the mass fraction of palladium and potassium are respectively 1% and 8%) are in mass ratio 1: 1 was mechanically ground in a mortar for 30 minutes to obtain a storage-reduction catalyst.

[0043] In this embodiment, the first catalyst is a palladium-supported magnesium-aluminum composite oxide, and the second catalyst is a palladium-potassium co-supported magnesium-aluminum composite oxide. Wherein, the first precious metal is palladium, and the first carrier is magnesium-aluminum composite oxide (the specific surface area is 90m 2 / g, and the molar ratio of magnesium to aluminum is 3:1); the second noble metal is palladium, the storage component is potassium, and the second carrier is magnesium-aluminum composite oxide (the specific surface area is 90m 2 / g, and the molar ratio of magnesium to...

Embodiment 2

[0046] Platinum-supported alumina (the mass fraction of platinum is 2%) and platinum-barium co-supported alumina (the mass fractions of platinum and barium are 2% and 20%, respectively) were mechanically mixed in a mortar at a mass ratio of 0.5:1. After stirring for 40 minutes, a storage-reduction catalyst was obtained.

[0047] In this embodiment, the first catalyst is platinum-supported alumina, and the second catalyst is platinum-barium co-supported alumina. Wherein, the first precious metal is platinum, and the first carrier is alumina (specific surface area is 300m 2 / g); the second noble metal is platinum, the storage component is barium, and the second carrier is alumina (specific surface area is 300m 2 / g).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com