Electrode material for lithium-air battery and preparation method of electrode material

An electrode material, air battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of increasing battery cost, achieve the effect of reducing battery cost and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

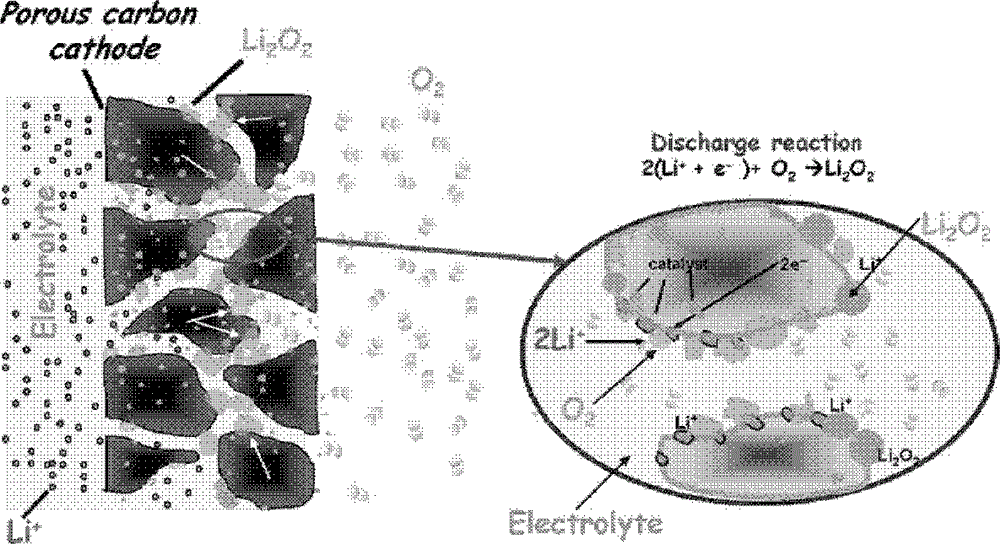

Problems solved by technology

Method used

Image

Examples

Embodiment 1

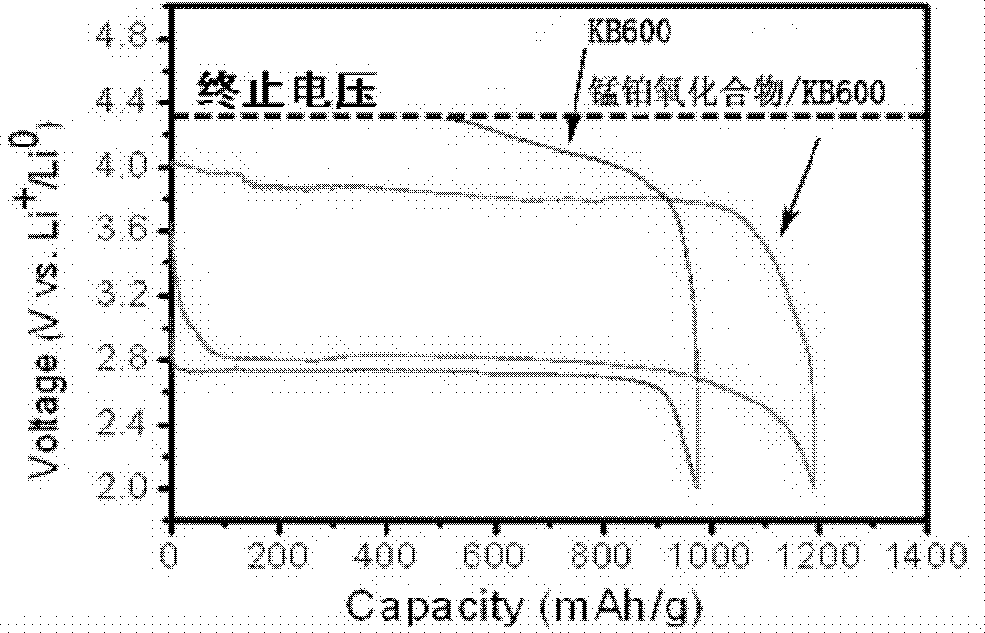

[0032] Accurately weigh 200mg of KB600 carbon powder, add 100g of deionized water and stir until completely dispersed, then adjust the pH value of the suspension to 10 with 0.1M sodium hydroxide aqueous solution. To the above reaction system, add 10ml of KMnO with a concentration of 0.1M 4 and 1ml of 0.1M H 2 PtCl 6 mixed solution, stir to mix evenly. Condensate and reflux in an oil bath at 60°C for 5 hours, filter and wash with suction, dry in vacuum at 80°C for 24 hours, and heat-treat the sample at 350°C for 4 hours to obtain manganese platinum oxide supported on KB600.

[0033]Electrode material and PTFE (mass ratio 8:1), stirred in ethanol, ultrasonically oscillated and mixed evenly to obtain a paste mixture, obtained electrode pancakes by rolling method, punched into 2cm 2 The disc was cold-pressed with a nickel mesh and dried to prepare an electrode.

[0034] Use a 2016 button battery case as the battery package, place the lithium sheet, the electrolyte diaphragm ma...

Embodiment 2

[0038] Accurately weigh 300mg of XC-72 carbon powder, add 100g of deionized water and stir until completely dispersed, then use 0.1M hydrochloric acid aqueous solution to adjust the pH value of the suspension to 5. To the above reaction system, add 5ml of KMnO with a concentration of 0.1M 4 and 2ml of 0.1M FeCl 3 mixed solution, stir to mix evenly. Condensation and reflux in an oil bath at 60°C for 5 hours, suction filtration and washing, vacuum drying at 80°C for 24 hours, and heat treatment of the sample at 300°C for 3 hours to obtain manganese-iron oxides supported on XC-72.

[0039] The electrode was prepared by the method of Example 1, the battery was assembled, and the performance evaluation was performed.

Embodiment 3

[0041] Accurately weigh 300 mg of carbon nanotubes, add 100 g of deionized water and stir until completely dispersed, then use 0.1 M hydrochloric acid aqueous solution to adjust the pH value of the suspension to 6. To the above reaction system, add 6ml of KMnO with a concentration of 0.1M 4 and 2ml of 0.1M Co(NO 3 ) 2 mixed solution, stir to mix evenly. Under an ultrasonic environment, the reaction was carried out for 5 hours, and the reaction temperature was kept constant at 30°C. After suction filtration and washing, vacuum drying at 80° C. for 24 hours, heat treatment of the sample at 350° C. for 3 hours, to obtain manganese cobalt oxide supported on carbon nanotubes.

[0042] The electrode was prepared by the method of Example 1, the battery was assembled, and the performance evaluation was performed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com