Nuclear reactor integrating lower end socket integrity profiling and forging method

A nuclear reactor and head technology, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of uneven and insufficient deformation of forgings, low material utilization, external dimensions and wall thickness Large and other problems, to achieve the effect of improving material utilization, sufficient and uniform deformation, and continuous fiber streamline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The processing steps of the integral profiling forging method of the super-large thick-walled integrated lower head of the nuclear reactor with asymmetric and non-contour heights according to the present invention are as follows:

[0033] Before the die forging, the billet is made by free forging to ensure that the billet is forged and compacted, and then the die forging is carried out. The specific forging steps are as follows:

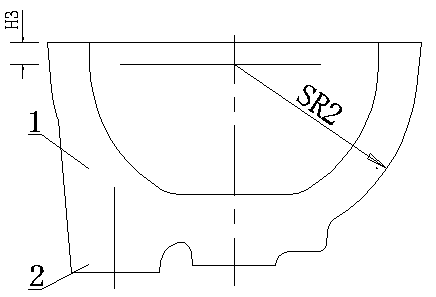

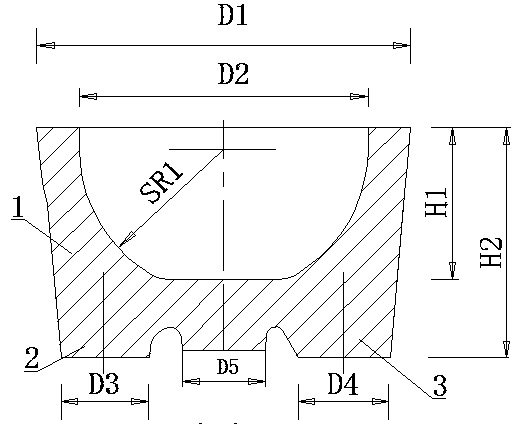

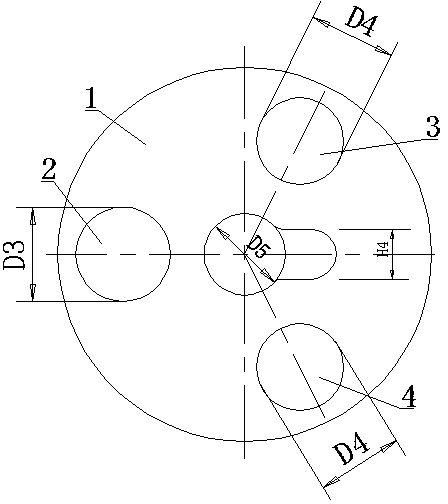

[0034] step one:

[0035] The structure of the head for nuclear power is as follows: figure 1 , figure 2 , image 3 As shown, according to the requirements of the drawing of the head 1 to be processed, the outer diameter of the opening end of the head is D1, the inner diameter is D2, the total height of the outer spherical top of the head is H2, the radius of the inner semicircle is SR1, and the inner spherical top of the head is The height of the heart distance from the upper end is H3, the total height from the bottom of the inner hemisp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com