Ultraviolet photoelectric sensor positioning fixture and mounting method thereof

A positioning fixture and electric sensor technology, applied in the field of ultraviolet flame detection, can solve the problems of affecting the assembly progress, size cannot be guaranteed, outflow phenomenon, etc., and achieve the effect of improving assembly efficiency, good working condition, and saving work flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

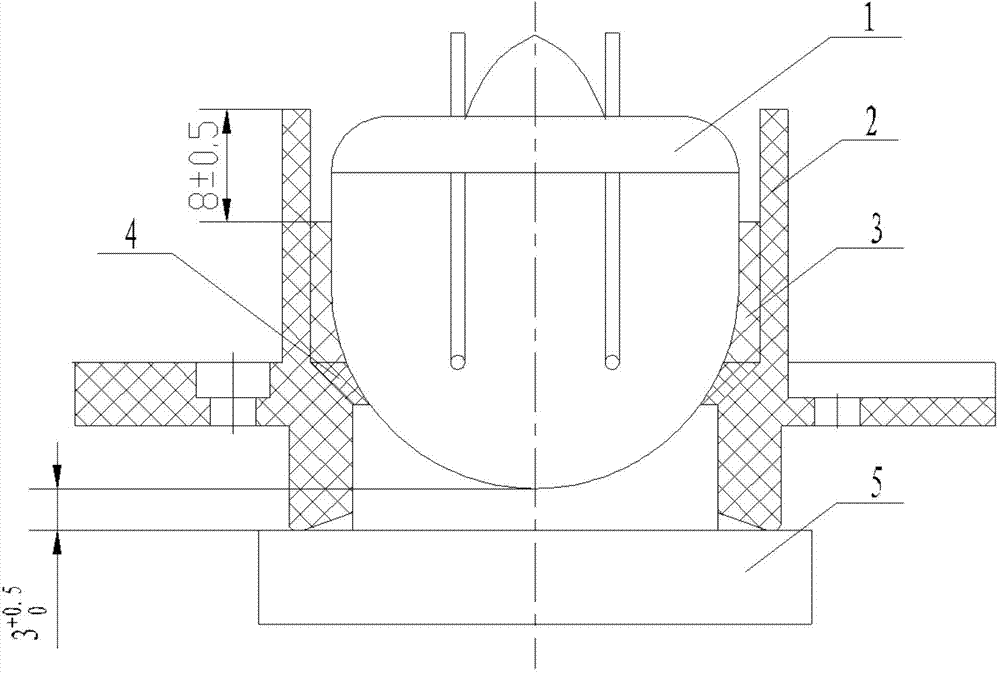

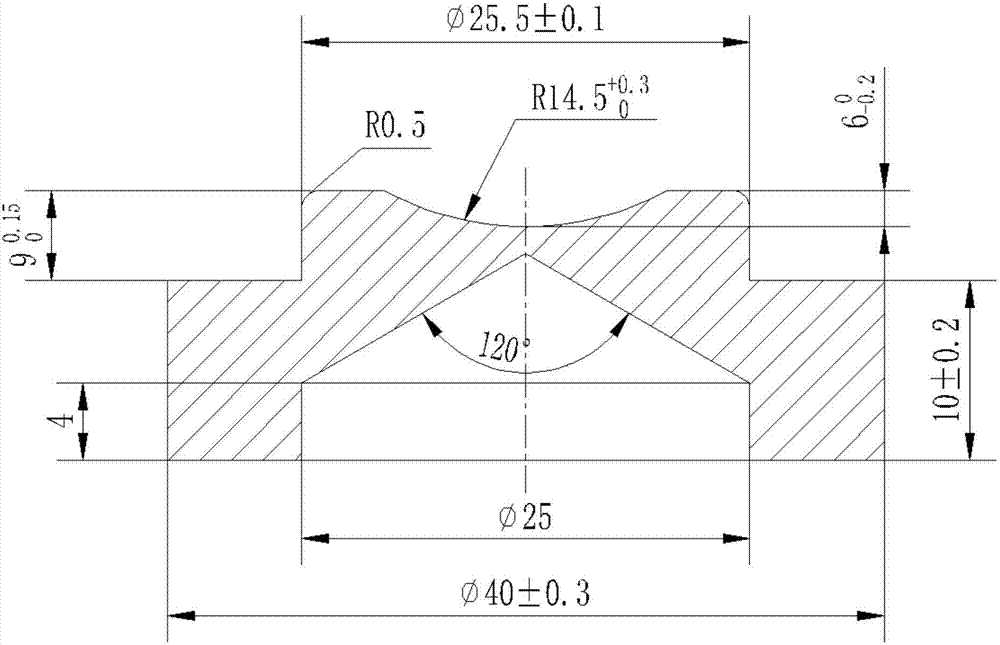

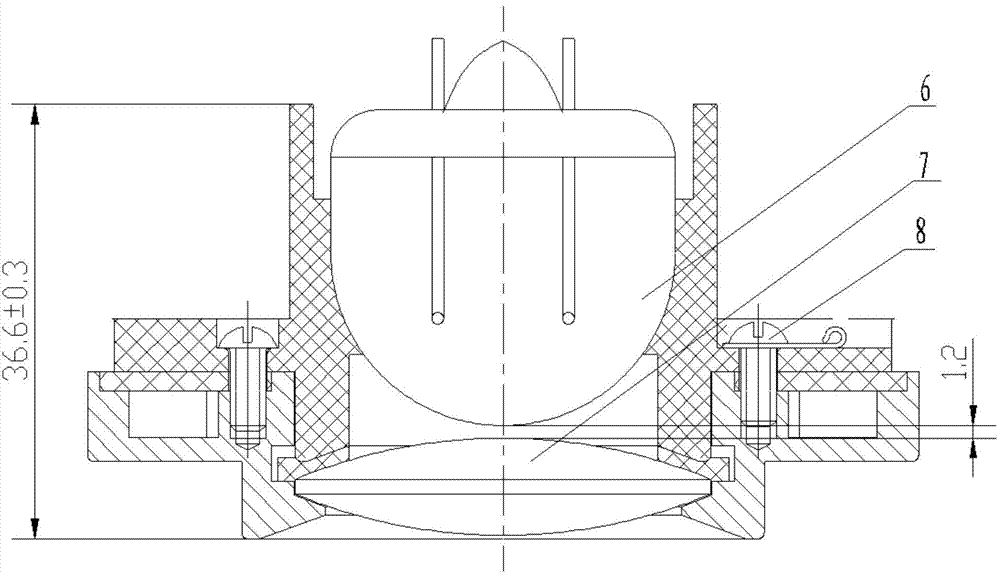

[0022] Describe the present invention below in conjunction with specific embodiment:

[0023] The ultraviolet flame detection technology can detect the invisible ultraviolet light with a wavelength of 180nm ~ 290nm produced by the combustion chamber of the aero-engine. Its gas-filled UV photocell acts as a sensitive element that detects invisible UV radiation.

[0024] The working principle of the ultraviolet photoelectric cell assembly and the ultraviolet photoelectric sensor that needs to be assembled in this embodiment is: when the oil-air mixture in the engine combustion chamber is burned, ultraviolet radiation is generated, and after being focused by a quartz convex lens, it breaks down the gas in the sensitive medium ultraviolet photoelectric cell, and the ultraviolet radiation The photocell is turned on and outputs a voltage signal. Judging the flame combustion in the combustion chamber by the data segment of the output voltage signal, when the effective value of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com