Pump concrete doped with low-quality recycled micropowder and low-quality recycled aggregate

A technology for pumping concrete and regenerated micropowder, which is applied in the field of construction waste recycling and building material waste utilization. It can solve the problems of construction waste being piled up everywhere, discarded, and occupying land, and achieves reduced water absorption, excellent mechanical properties and durability. , easy pumping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

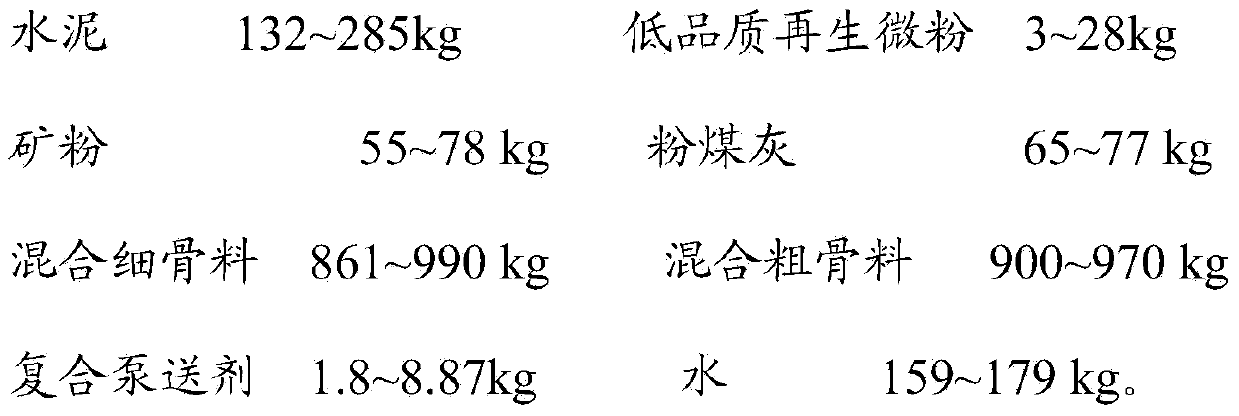

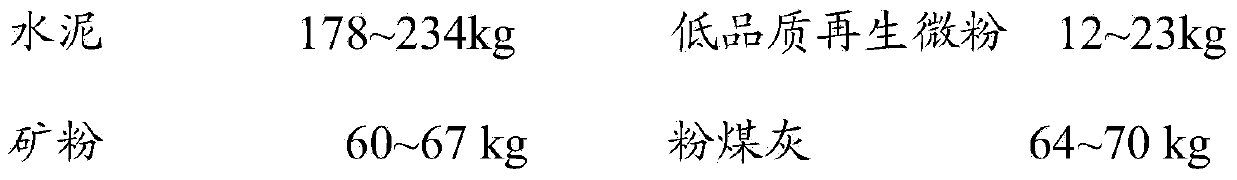

Embodiment 1

[0061] The pumped concrete described in this embodiment is calculated by pumping concrete per cubic meter, and consists of the following quality raw materials: 132kg of cement, 28kg of low-quality recycled micropowder, 55kg of mineral powder, 65kg of fly ash, 990kg of mixed fine aggregate, and 990kg of mixed coarse aggregate. 900kg of aggregate, 3.64kg of composite pumping agent, and 179kg of water; wherein, the mixed fine aggregate is composed of low-quality recycled fine aggregate and ordinary fine aggregate, and the brick content of the low-quality recycled fine aggregate is 20wt% , the low-quality recycled fine aggregate accounts for 40wt% of the total mass of the mixed fine aggregate, the mixed coarse aggregate is composed of low-quality recycled coarse aggregate and ordinary coarse aggregate, and the low-quality recycled coarse aggregate is used in bricks The content is 20wt%, and the low-quality recycled coarse aggregate accounts for 60wt% of the total mass of the mixed ...

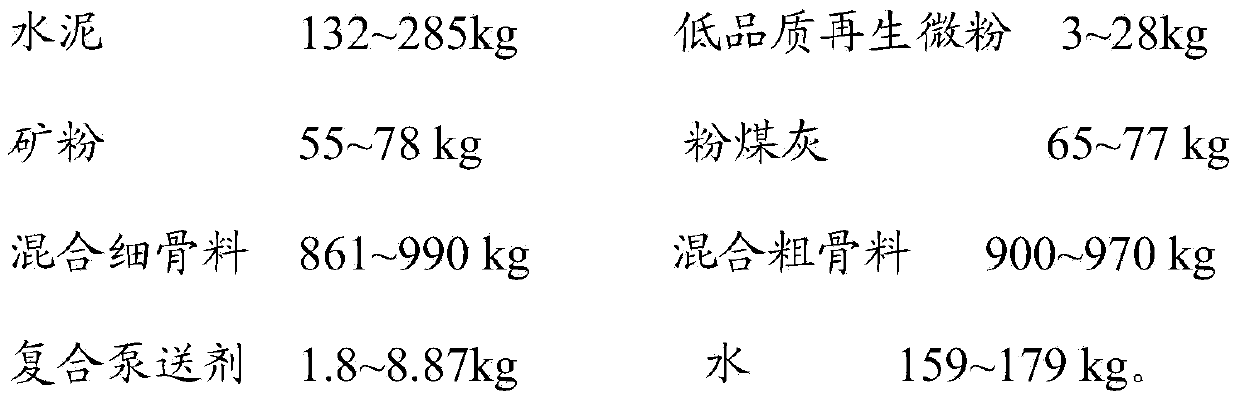

Embodiment 2

[0063] The pumped concrete described in this embodiment is calculated by pumping concrete per cubic meter, and consists of the following quality raw materials: 178kg of cement, 23kg of low-quality recycled micropowder, 60kg of mineral powder, 68kg of fly ash, 910kg of mixed fine aggregate, and 910kg of mixed coarse aggregate. 930kg of aggregate, 1.8kg of composite pumping agent, and 175kg of water; wherein, the mixed fine aggregate is composed of low-quality recycled fine aggregate and ordinary fine aggregate, and the brick content of the low-quality recycled fine aggregate is 40wt% , the low-quality recycled fine aggregate accounts for 30wt% of the total mass of the mixed fine aggregate, the mixed coarse aggregate is composed of low-quality recycled coarse aggregate and ordinary coarse aggregate, and the low-quality recycled coarse aggregate is used in bricks The content is 40wt%, and the low-quality recycled coarse aggregate accounts for 50wt% of the total mass of the mixed c...

Embodiment 3

[0065] The pumped concrete described in this embodiment is calculated by pumping concrete per cubic meter, and consists of the following quality raw materials: 197kg of cement, 17kg of low-quality recycled micropowder, 62kg of mineral powder, 70kg of fly ash, 884kg of mixed fine aggregate, and 884kg of mixed coarse aggregate. Aggregate 958kg, compound pumping agent 4.84kg, water 169kg; Wherein, wherein, described mixed fine aggregate is made up of low-quality recycled fine aggregate and ordinary fine aggregate, and the brick content of described low-quality recycled fine aggregate is 50wt%, the low-quality recycled fine aggregate accounts for 20wt% of the total mass of the mixed fine aggregate, the mixed coarse aggregate is composed of low-quality recycled coarse aggregate and ordinary coarse aggregate, and the low-quality recycled coarse aggregate The medium brick content is 50wt%, the low-quality recycled coarse aggregate accounts for 40wt% of the total mass of the mixed coar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com