A kind of method of joint production o-sulfonate sodium benzaldehyde and o-chlorobenzoic acid

A technology of o-chlorobenzoic acid and o-sodium sulfonate, which is applied in the direction of sulfonate preparation, carboxylate preparation, organic chemistry, etc., can solve the problems that cannot be further processed, achieve the reduction of organic matter content, realize recycling, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step one: the following raw materials are respectively used: o-chlorobenzaldehyde 2000kg, Na 2 SO 3 2245kg, PEG-60080kg, H 2 08000kg, add all into the autoclave and heat up to 170°C, keep warm for 10 hours, depressurize to 95°C and discharge.

[0028] Transfer the synthesized material into a still kettle and distill under reduced pressure until the weight of distilled water is 4000kg, heat filter, crystallize the filtrate, cool down to normal temperature and centrifuge.

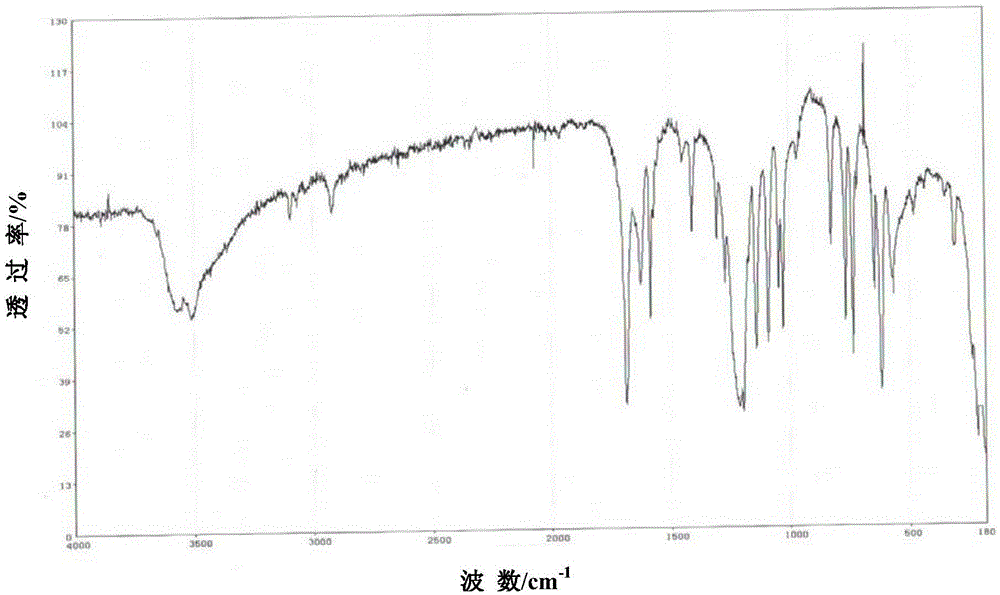

[0029] The reaction is synthesized to obtain 2350 kg of sodium benzaldehyde o-sulfonate, and the infrared spectrum is as follows figure 1 Shown; o-sodium sulfonate benzaldehyde waste water 1500L.

[0030] Step 2: Put 1500L of sodium o-sulfonate benzaldehyde wastewater into the reactor, adjust the pH to 1.0 with 50% sulfuric acid, and raise the temperature to 100°C-105°C; The crude product of o-chlorobenzoic acid was obtained; the crude product of o-chlorobenzoic acid was sprayed and washed with wat...

Embodiment 2

[0032] Step one: the following raw materials are respectively used: o-chlorobenzaldehyde 2000kg, Na 2 SO 3 2245kg, PEG-20080kg, H 2 06000kg, all added to the autoclave and heated to 170°C, kept warm for 10 hours, cooled to 95°C and discharged.

[0033] Transfer the synthesized material into a still kettle and distill under reduced pressure until the weight of distilled water is 4000kg, heat filter, crystallize the filtrate, cool down to normal temperature and centrifuge.

[0034] Reaction synthesis obtains 2250 kg of sodium benzaldehyde o-sulfonate and 1500 L of sodium benzaldehyde o-sulfonate waste water. Step 2: Put 1500L of sodium o-sulfonate benzaldehyde wastewater into the reactor, adjust the pH to 1.0 with 50% sulfuric acid, and raise the temperature to 100°C-105°C; The crude product of o-chlorobenzoic acid was obtained; the crude product of o-chlorobenzoic acid was sprayed and washed with water, and after drying, 115 kg of crystals of o-chlorobenzoic acid were obtain...

Embodiment 3

[0036] Step one: the following raw materials are respectively used: o-chlorobenzaldehyde 2000kg, Na 2 SO 3 2245kg, PEG-80080kg, H 2 O10000kg, add all into the autoclave and heat up to 170°C, keep warm for 10 hours, cool down to 95°C and discharge.

[0037] Transfer the synthesized material into a still kettle and distill under reduced pressure until the weight of distilled water is 4000kg, heat filter, crystallize the filtrate, cool down to normal temperature and centrifuge.

[0038] Reaction synthesis obtains 2300 kg of sodium benzaldehyde o-sulfonate and 1500 L of sodium benzaldehyde o-sulfonate waste water. Step 2: Put 1500L of sodium o-sulfonate benzaldehyde wastewater into the reactor, adjust the pH to 1.0 with 50% sulfuric acid, and raise the temperature to 100°C-105°C; The crude product of o-chlorobenzoic acid was obtained; the crude product of o-chlorobenzoic acid was sprayed and washed with water, and after drying, 117 kg of crystals of o-chlorobenzoic acid were ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com