A kind of elastic epoxy polyurethane wood floor paint and preparation method thereof

A technology of epoxy polyurethane and wood flooring, applied in polyurea/polyurethane coatings, coatings, etc., to achieve the effects of improving wear resistance and strength, improving anti-skid and noise reduction, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0020] An elastic epoxy polyurethane wood floor paint, which is prepared by mixing a hydroxyl component and an NCO component in a mass ratio of 1:0.8-1.2, wherein the hydroxyl component and the NCO component are respectively prepared by the following components and weight ratios into:

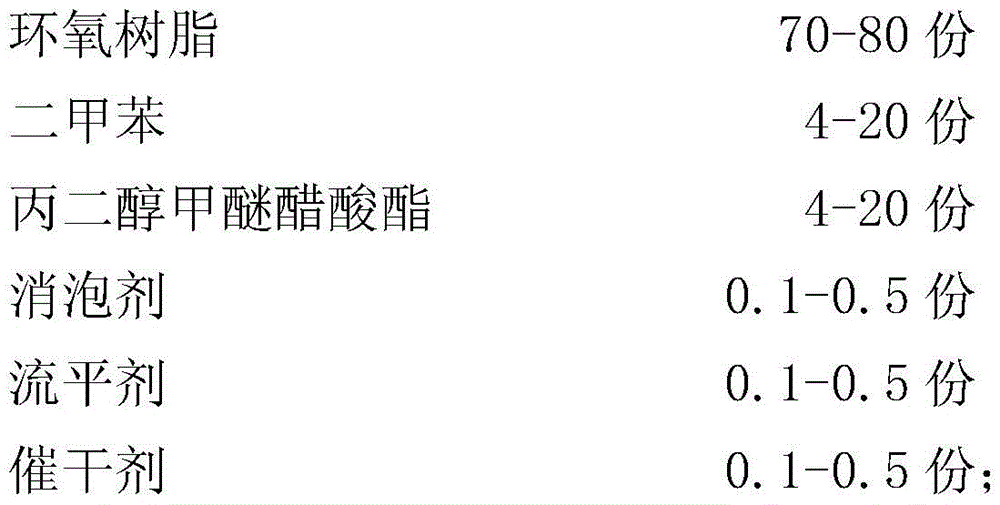

[0021] Wherein the composition and parts by weight of the hydroxyl component are as follows:

[0022]

[0023]

[0024] Among them, the NCO component is composed of moisture curing agent.

[0025] The preparation method of above-mentioned elastic epoxy polyurethane wood floor paint, comprises the steps:

[0026] (1), the hydroxyl component is prepared according to the following preparation method:

[0027] Add epoxy resin, xylene, PMA, defoamer, leveling agent and drier into the container in sequence, and disperse in the mixer at 1000-1200 rpm for 10-15 minutes until mixed evenly;

[0028] (2), wherein the NCO component adopts a moisture curing agent; after the hydroxyl component is pr...

Embodiment 1

[0031] Embodiment 1: A kind of elastic epoxy polyurethane wood floor paint is mixed by the mass ratio of 1:0.8 by hydroxyl component and NCO component, and wherein hydroxyl component and NCO component are respectively composed of the following components and parts by weight than formulated with:

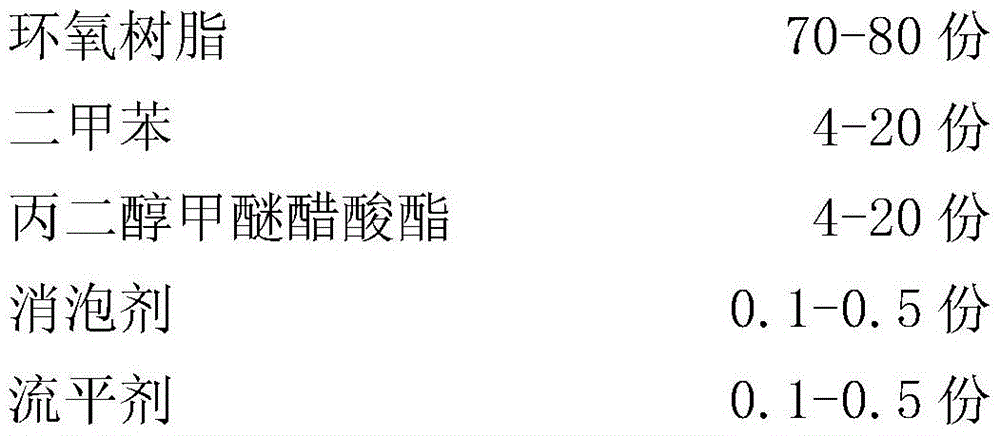

[0032] Wherein the composition and parts by weight of the hydroxyl component are as follows:

[0033]

[0034] Among them, the NCO component is composed of moisture curing agent.

[0035] The preparation method of above-mentioned elastic epoxy polyurethane wood floor paint comprises the steps:

[0036] (1), the hydroxyl component is prepared according to the following preparation method:

[0037] Add 70 parts of epoxy resin, 15 parts of xylene, 15 parts of PMA, 0.1 part of defoamer, 0.3 part of leveling agent, and 0.2 part of drier into the container in sequence, and disperse in the mixer at 1000 rpm for 15 minutes to mix well;

[0038] (2), wherein the NCO component uses a mo...

Embodiment 2

[0042] Embodiment 2: A kind of elastic epoxy polyurethane wood floor paint, is mixed by the mass ratio of 1:1 by hydroxyl component and NCO component, and wherein hydroxyl component and NCO component are respectively composed of the following components and parts by weight than formulated with:

[0043] Wherein the composition and parts by weight of the hydroxyl component are as follows:

[0044]

[0045] Among them, the NCO component is composed of moisture curing agent.

[0046] The preparation method of above-mentioned elastic epoxy polyurethane wood floor paint comprises the steps:

[0047] (1), the hydroxyl component is prepared according to the following preparation method:

[0048] Add 75 parts of epoxy resin, 15 parts of xylene, 10 parts of propylene glycol methyl ether acetate, 0.1 part of defoamer, 0.3 part of leveling agent, and 0.2 part of drier into the container in sequence, and in the mixer at 1100 rpm Disperse for 12 minutes per minute until evenly mixed;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com