Flow polymerase chain reaction (PCR) circulating heating apparatus based on capillaries and heating method

A cyclic heating and chain reaction technology, applied in chemical instruments and methods, specific-purpose bioreactors/fermenters, heating or cooling equipment, etc., can solve the problem of uneven heating of samples, low repeatability, and easy leakage and other problems, to achieve the effect of easy and uniform temperature distribution, good repeatability, and improved heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

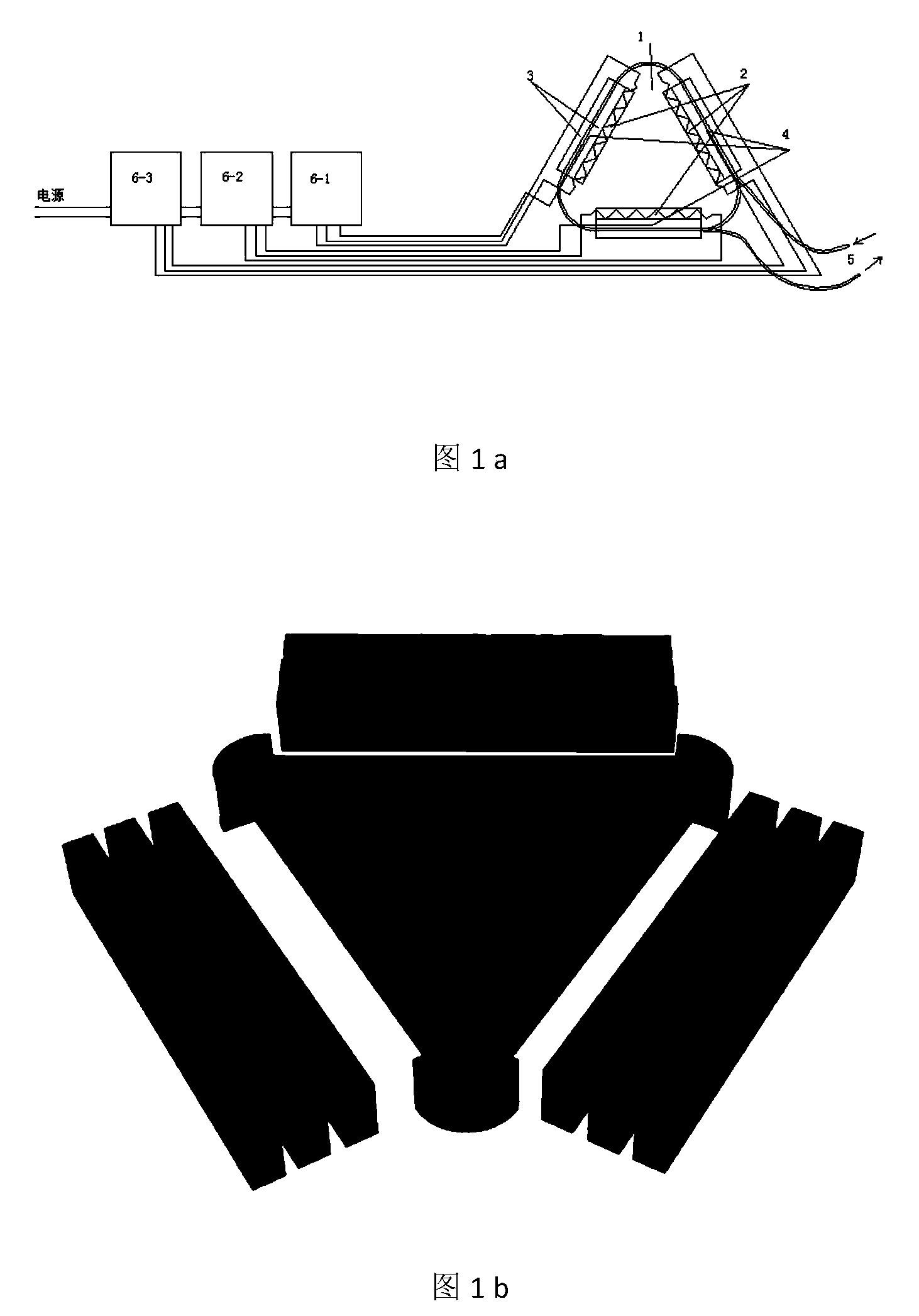

[0023] A capillary-based flow polymerase chain reaction spiral heater of the present invention:

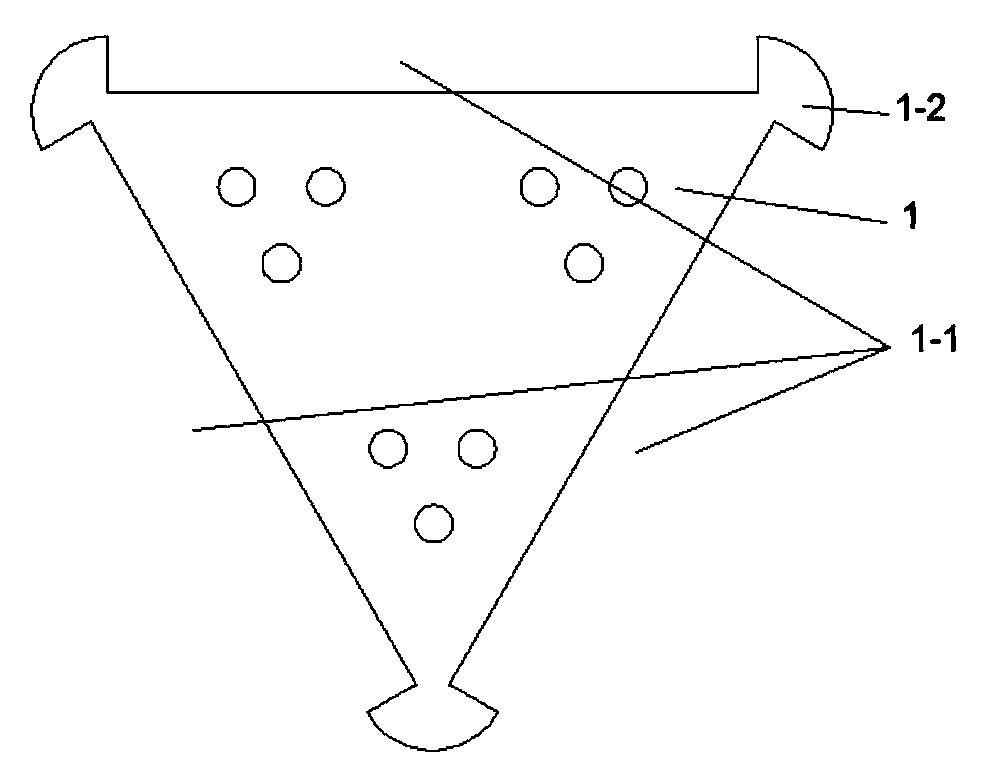

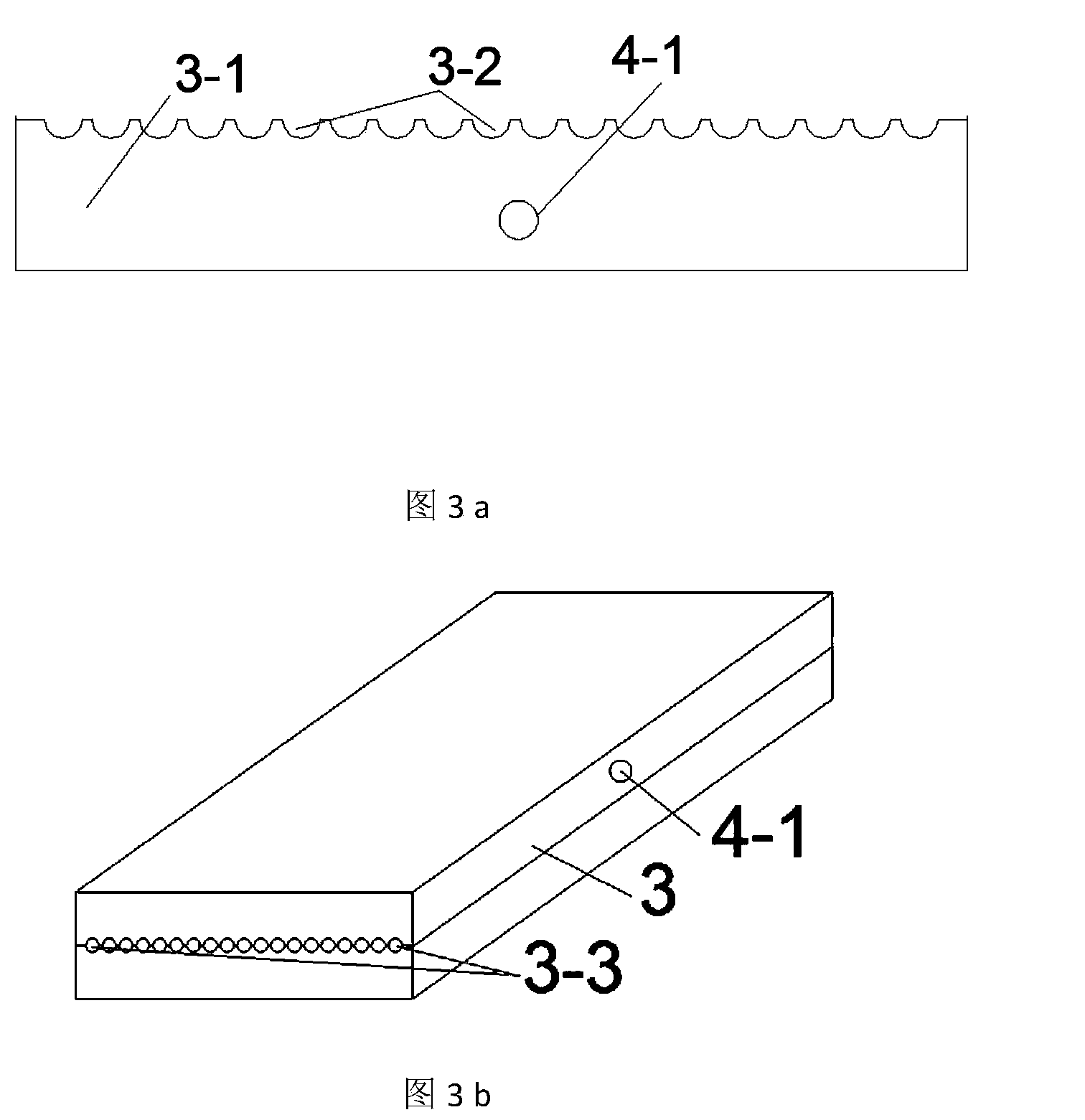

[0024] The whole device is composed of a bracket (1), a heating plate (2), a constant temperature channel (3), a capillary tube (5) and a temperature controller (6). Each side of the triangular bracket (1) has a channel (1-1); the constant temperature channel is composed of two identical modules (3-1, 3-2) that are buckled together. The modules (3-1, 3) -2) It is in the shape of a rectangular parallelepiped, with a row of semicircular capillary channels (3-3) engraved on one side of the modules (3-1, 3-2), the capillary (5) is a flexible pipe, and the temperature controller (6) ) consists of three temperature controllers (6-1, 6-2, 6-3), which independently control the temperature of each heating plate;

[0025] The heating plate (2) and the module (3-1) are installed in sequence in each channel (1-1) on the side of the bracket (1); the module (3-1) has the capillary channel (3-3...

Embodiment 2

[0030] The triangular bracket is made of plexiglass, 20mm thick, 80mm wide and 8mm deep. The heating plate adopts an aluminum plate heater, the power supply is 24V DC power supply, and the power is 20W. A single module of the constant temperature channel is an aluminum block, with a thickness of 4mm, a length of 80mm, and a width of 20mm. The diameter of the semicircular channel is 0.8mm and the spacing is 0.2mm. The capillary adopts a silicone tube with an outer diameter of 0.8 mm. The temperature controller purchases the REX-C700 temperature controller. Three groups of heating groups, two for heating and one for cooling, constitute two-temperature PCR. All components are integrated on a flat panel and finally enclosed in a case.

Embodiment 3

[0032] The triangular bracket is made of plastic, 20mm thick, 80mm wide and 8mm deep. The heating plate adopts stainless steel electric heater, the power supply is 24V DC power supply, and the power is 20W. A single module of the constant temperature channel is made of stainless steel, with a thickness of 4mm, a length of 80mm and a width of 20mm. The diameter of the semicircular channel is 0.8mm and the spacing is 0.2mm. The capillary adopts a silicone tube with an outer diameter of 0.8 mm. The temperature controller purchases the REX-C700 temperature controller. The temperature of each group is controlled and displayed by an independent PID controller; three groups of heating groups, two for heating, control 65 and 95 degrees respectively; the remaining group is used for cooling (using a fan), which constitutes a two-temperature PCR. All components are integrated on a flat panel and finally enclosed in a case.

[0033] The capillary-based flow polymerase chain reaction (P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com