Raw material and method for producing magnesium pellets by using belt type machine

A pelletizing and belt-type machine technology is applied in the production field of magnesia pellet raw material and magnesia pellet production field by belt-type machine. Easier to stably control, improve metallurgical properties, and the effect of improving metallurgical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention aims at developing a magnesia pellet produced by a belt machine and a production method thereof aiming at the belt machine process, and determines the drying, preheating, roasting system.

[0025] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

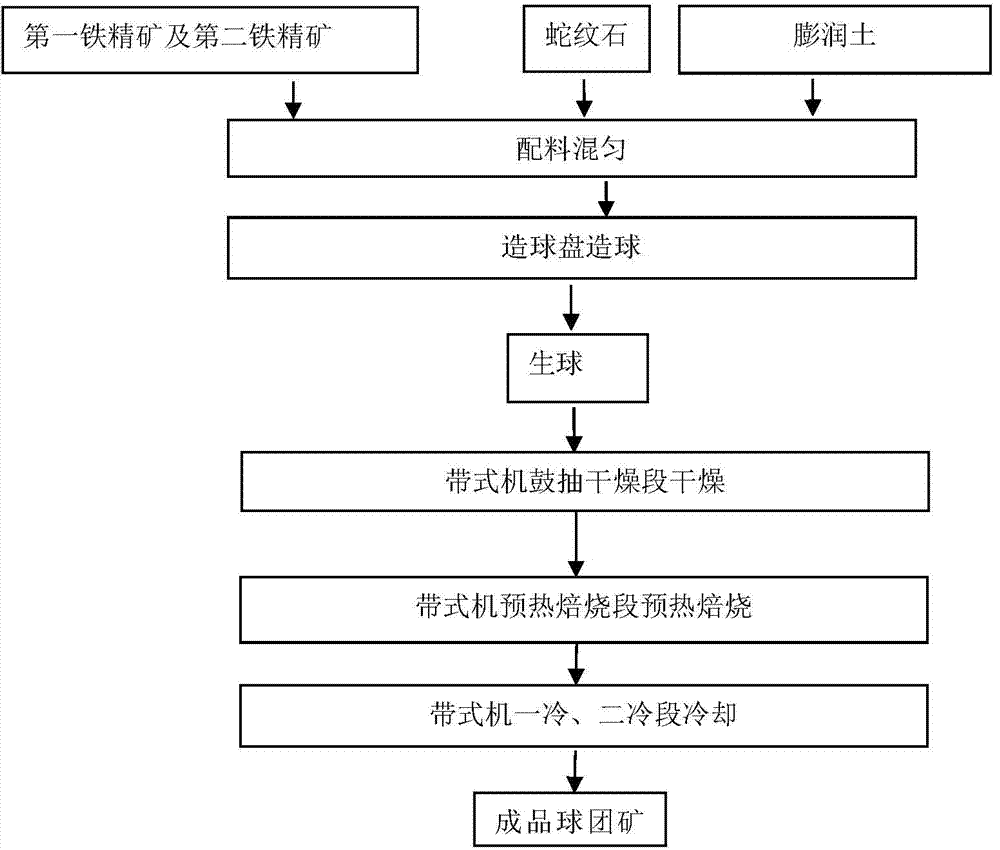

[0026] Such as figure 1 Shown is the flow chart of the method for producing magnesia pellets with a belt machine in the present invention.

[0027] The method for producing magnesia pellets by belt machine comprises the following steps:

[0028] Step 1: First add 1.0-2.5% serpentine and 2% bentonite by weight to the iron-containing raw material, and fully mix in a strong mixer to obtain a mixture; the components of the iron-containing raw material include: the first Iron concentrate 0-45%, the second iron concentrate 55%-100%;

[0029] The chemical composition of the first iron concentrate is calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com