A Huff and Puff Oil Recovery Method for Combustion Reservoir

A technology of burning oil layers and oil layers, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of low-temperature oxidation of formations, improve single well productivity, ensure safe and smooth implementation, and avoid oil layer permeability decline Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

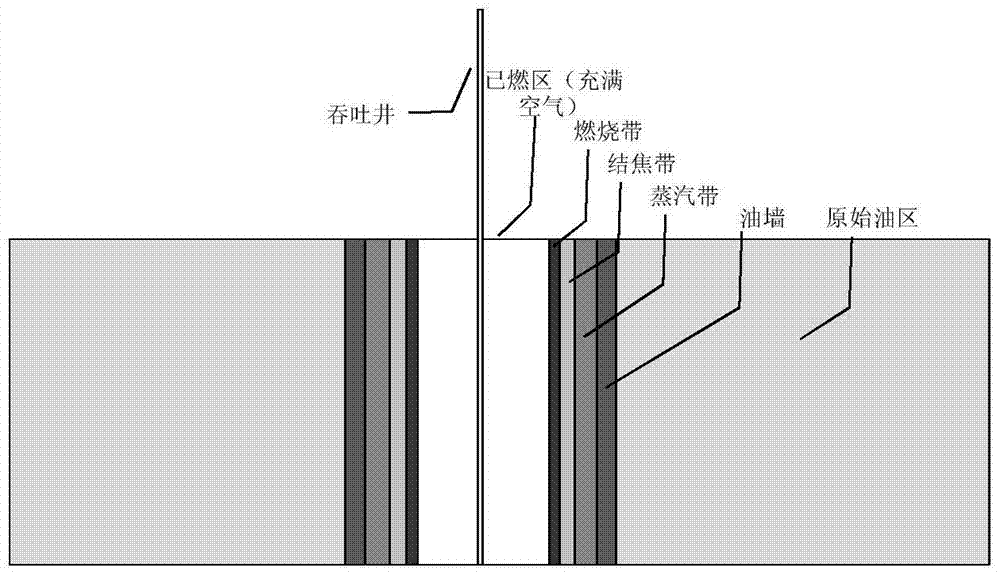

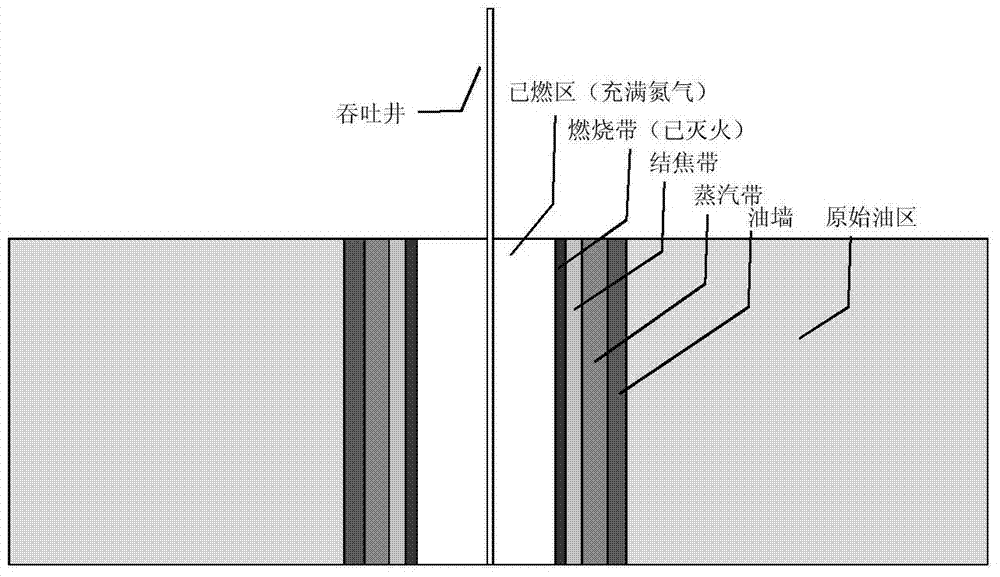

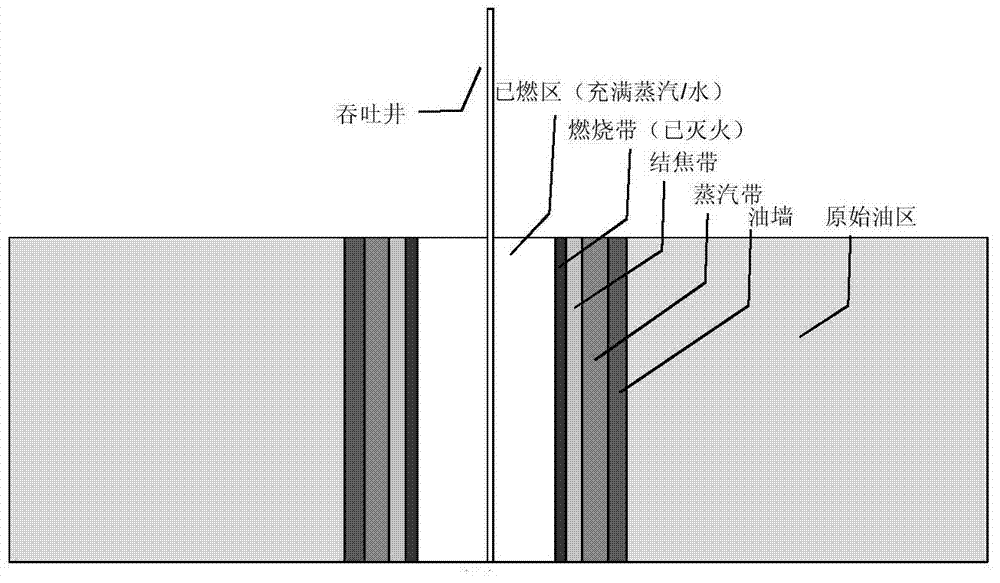

Method used

Image

Examples

Embodiment 1

[0032] In a high-pressure combustion tube with a length of 2m and an inner diameter of 5cm, an indoor experiment was carried out to control the oxygen concentration and prevent explosion accidents in the process of huff and puff recovery of incinerated oil layers. Inside the combustion tube is an artificial core with a permeability of about 3×10 -3 μm 2 , the porosity is 37%, the oil saturation is 78%, and the crude oil viscosity is 5100mPa.s. The gas injection pressure was maintained at about 4 MPa during the experiment.

[0033] 1) Use an electric igniter to ignite the oil sand at one end of the combustion tube, continuously inject air to push the combustion front to 0.5m along the combustion tube, and inject a total of 62 standard liters of air;

[0034] 2) Stop air injection, and transfer nitrogen gas 62×40×0.37÷300=3.05 standard liters;

[0035] 3) The well was recovered after 5 minutes of simmering, and the oxygen content in the produced gas components was less than 0...

Embodiment 2

[0037] In a high-pressure combustion tube with a length of 2m and an inner diameter of 5cm, an indoor experiment was carried out to control the oxygen concentration and prevent explosion accidents in the process of huff and puff recovery of incinerated oil layers. Inside the combustion tube is an artificial core with a permeability of about 3×10 -3 μm 2 , the porosity is 37%, the oil saturation is 78%, and the crude oil viscosity is 5100mPa.s. The gas injection pressure was maintained at about 4 MPa during the experiment.

[0038] 1) Use an electric igniter to ignite the oil sand at one end of the combustion tube, continuously inject air to push the combustion front to 0.5m along the combustion tube, and inject a total of 62 standard liters of air;

[0039] 2) Stop air injection, transfer steam 62×0.37÷900=0.0254 kg;

[0040] 3) The well was recovered after 5 minutes of simmering, and the oxygen content in the produced gas components was less than 0.5%, and no low-temperatu...

Embodiment 3

[0042] Reservoir 1 The depth of the reservoir is 800m; the thickness of the oil layer is 19.6m; the permeability of the oil layer is 610×10 -3 μm 2; Reservoir temperature 32°C; Crude oil viscosity 5100mPa.s; Crude oil density 0.9240g / cm 3 ; Oil saturation is 58.9%; formation fracture pressure is 18MPa.

[0043] 1) Perforate the oil well casing, and use hydraulic fracturing technology to press out 40m long artificial fractures, and fill the fractures with fracturing proppant. The main construction parameters include—accumulatively add 40m of ceramsite with a particle size of 0.425mm to 0.850mm 3 ; Prefluid 40m 3 ; Carrying fluid 105m 3 ; Displacement 3.5m 3 / min; the sand ratio increases step by step, from 10% to 80%, and after reaching the highest sand ratio, add 5m of displacement fluid 3 ;

[0044] 2) Use an electric heater to heat the injected air to above 400°C, continue to inject for 4 days to achieve ignition, and inject air at a speed of 6000m 3 / d;

[0045] 3)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com