Visual experiment system device used for simulating grouting plugging for water inrush of roadways

A technology of test system and grouting system, which is applied in the field of visual indoor test system device, can solve problems such as concealment unpredictability and complexity of engineering geological problems, and achieve moderate space occupation, easy operation and adjustment, and simple structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

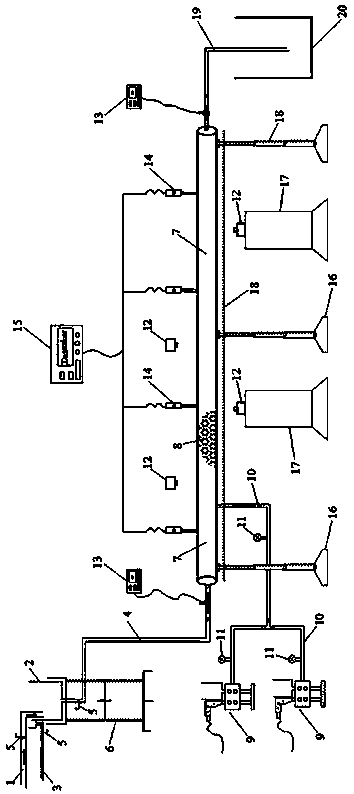

[0021] Such as figure 1 As shown, the present invention is realized in the following manner: a visual test system device for simulating roadway water inrush and grouting plugging according to the present invention consists of a dynamic water system, a roadway model system, a grouting system, a view recording system, and a flow monitoring system. System, data acquisition system, support system, waste liquid collection system consists of 8 parts. The dynamic water system consists of (1) water source pipe, (2) water collection tank, (3) drain pipe, (4) water inrush pipeline, (5) control valve and (6) water tank bracket; (6) water tank bracket is made of steel plate material Made to ensure the stability and safety of the whole part of the dynamic water system, it can freely adjust the lifting height, so that (2) the height of the water collection tank can be adjusted up and down, and different water inrush pressures can be simulated through the height of the water head; (1) one en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com