Electrically operated valve device combining hand-operated inner lifting stop valve with double-shaft motor

A technology of electric valve device and double-axis motor, which is applied in the direction of valve device, valve operation/release device, engine components, etc., can solve the problems of high maintenance cost, high cost, low efficiency, etc., and achieve simple structure, low cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

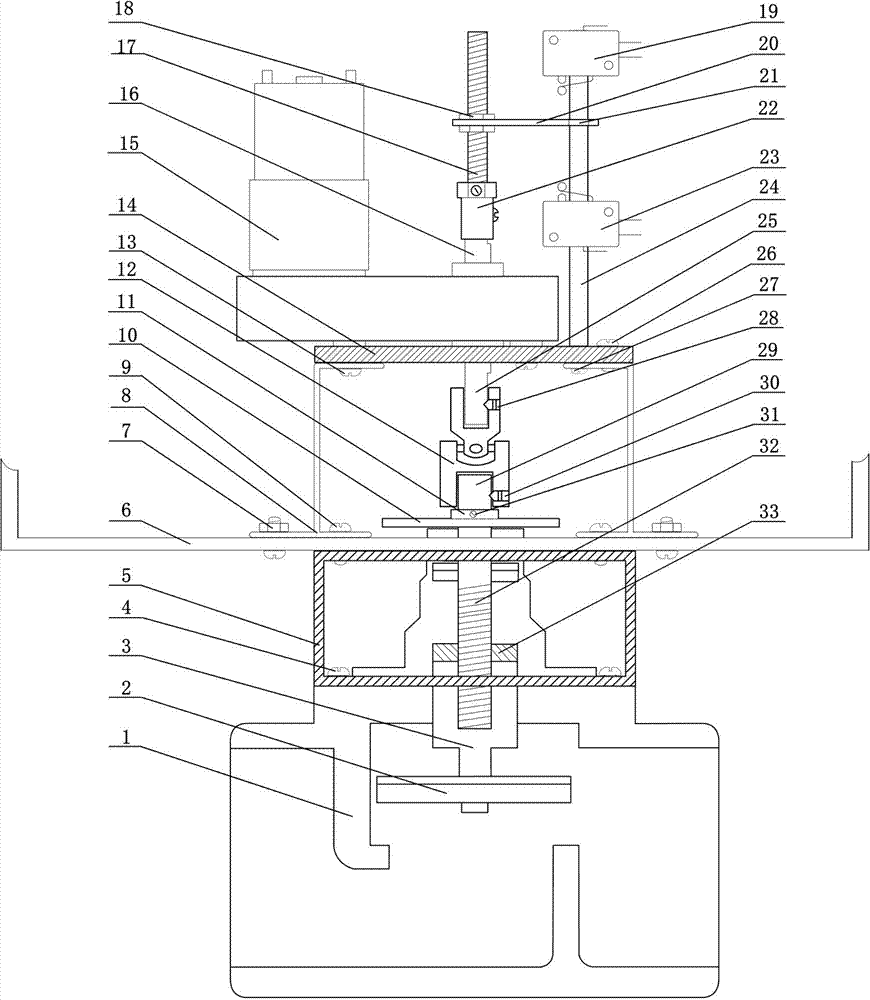

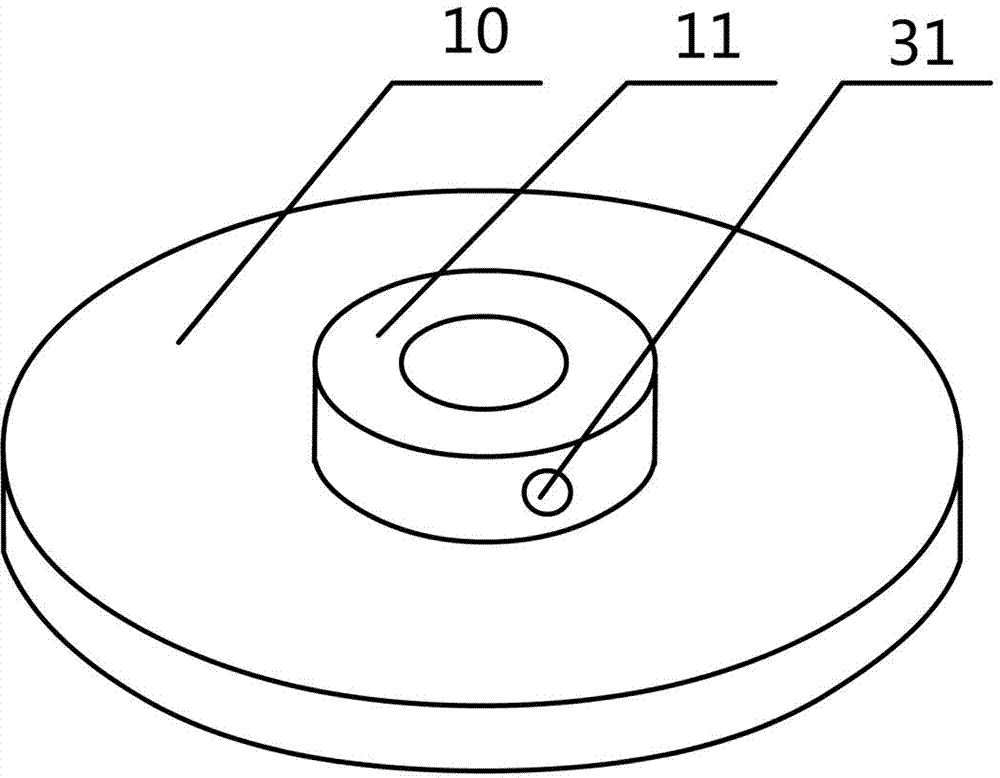

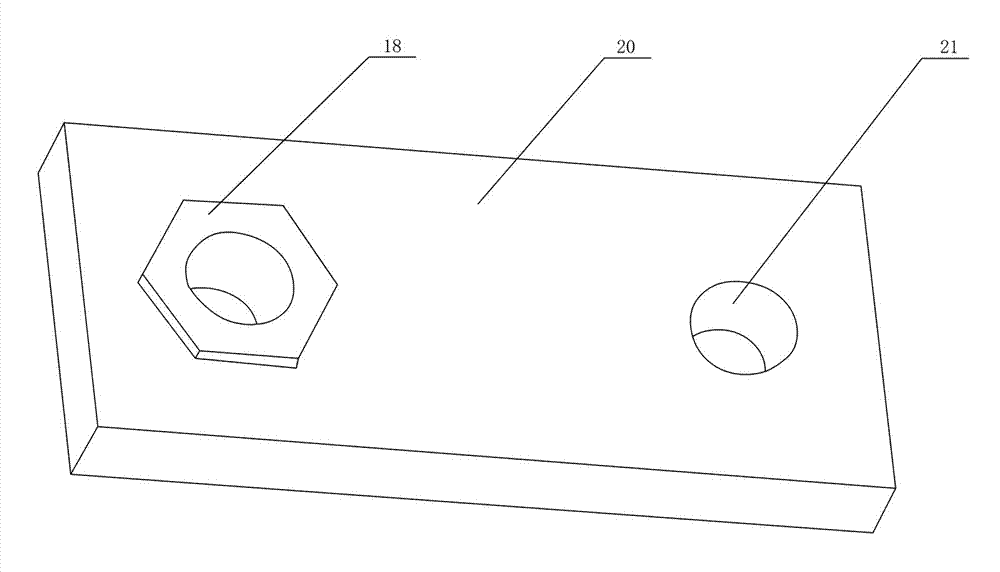

[0020] A manual internal lifting cut-off valve according to the present invention is equipped with a double-axis motor electric valve device. The electric valve controlled by the valve Bracket fixing bolts, inner bracket, inner and outer bracket fixing bolts, hand wheel, hand wheel fixing seat, universal joint, motor fixing screw, motor fixing plate, miniature geared motor, motor upper shaft, measuring position rotating rod, upper and lower position transmission plate bolts , Open valve travel switch, upper and lower position transmission plate, vertical rod hole of upper and lower position transmission plate, motor upper shaft coupling, valve closing travel switch, travel switch vertical rod, motor lower shaft, motor fixing plate fixing screw, vertical rod fixing screw , universal joint fastening motor shaft screw, valve drive shaft, universal joint fastening valve shaft screw, hand wheel fastening valve shaft screw, valve shaft thread, internal lifting body thread. Among the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com