Angle toggle electric valve device prepared from manual ball valve and additionally mounted micro gear motor

A technology of miniature geared motors and manual ball valves, applied in valve devices, valve operation/release devices, engine components, etc., can solve the problems of inadequate management, low efficiency, and high cost, and achieve easy maintenance, cost reduction, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

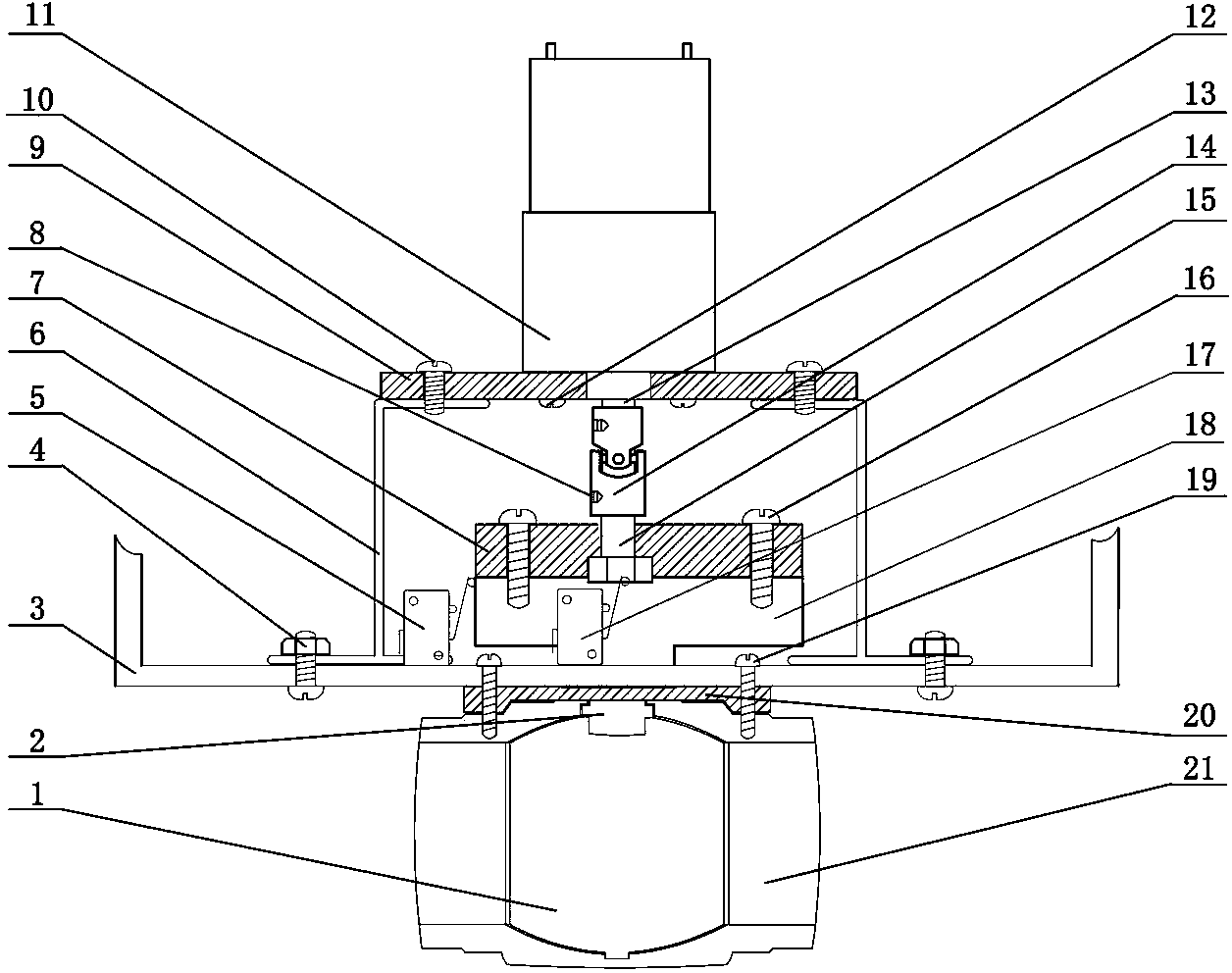

[0018] According to the present invention, a manual ball valve is equipped with a miniature deceleration motor to form an angle switch electric ball valve device. The controlled electric valve is composed of a manual ball valve ball, a valve shaft, a control box body, a support frame fixing bolt, a valve closing stroke switch, Support frame, handle connecting plate, universal joint fastening screw, motor fixing plate, motor fixing plate bolt, miniature geared motor, miniature geared motor fixing screw, miniature geared motor output shaft, universal joint, power transmission bolt, handle connecting plate Fixing screw, valve opening travel switch, valve manual handle, box valve connecting screw, box valve connecting plate, and ball valve body; among them (14) universal joint is connected to (11) miniature geared motor and (18) valve manual handle, (11) The miniature deceleration motor drives (18) valve manual handle, (2) valve shaft and (1) manual ball valve ball to rotate throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com