Method for designing fuzzy PI controller of Delta robot movement mechanism

A technology of motion mechanism and design method, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as inaccurate control, limited ability of PI controller to deal with system uncertainty, instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

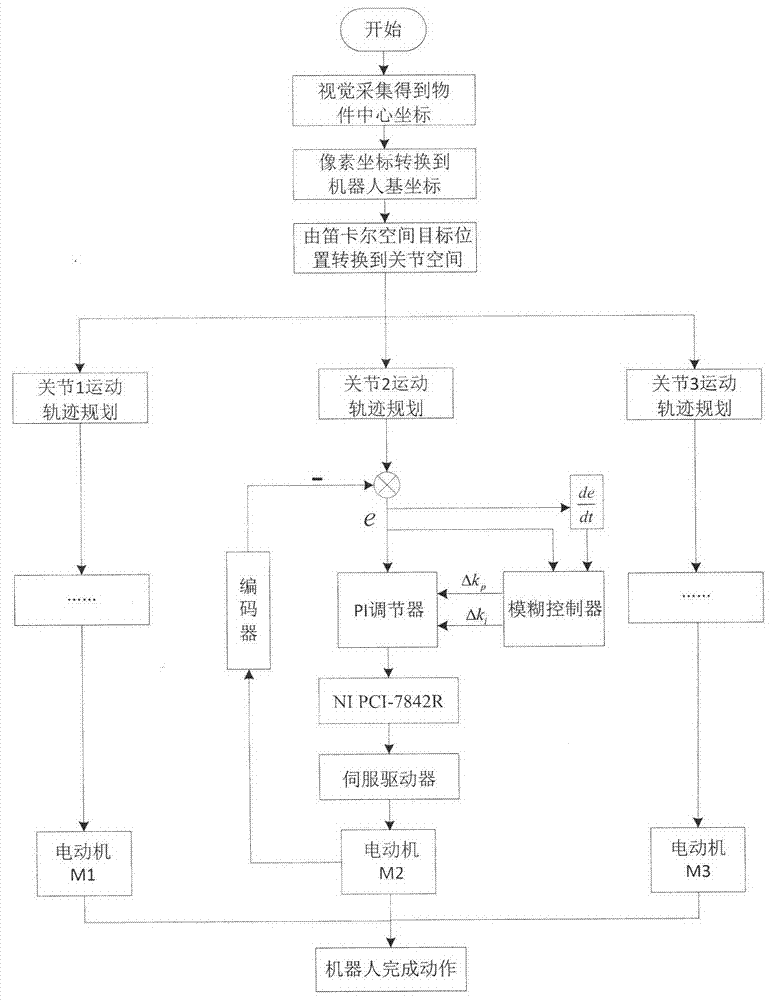

[0039] The specific steps are:

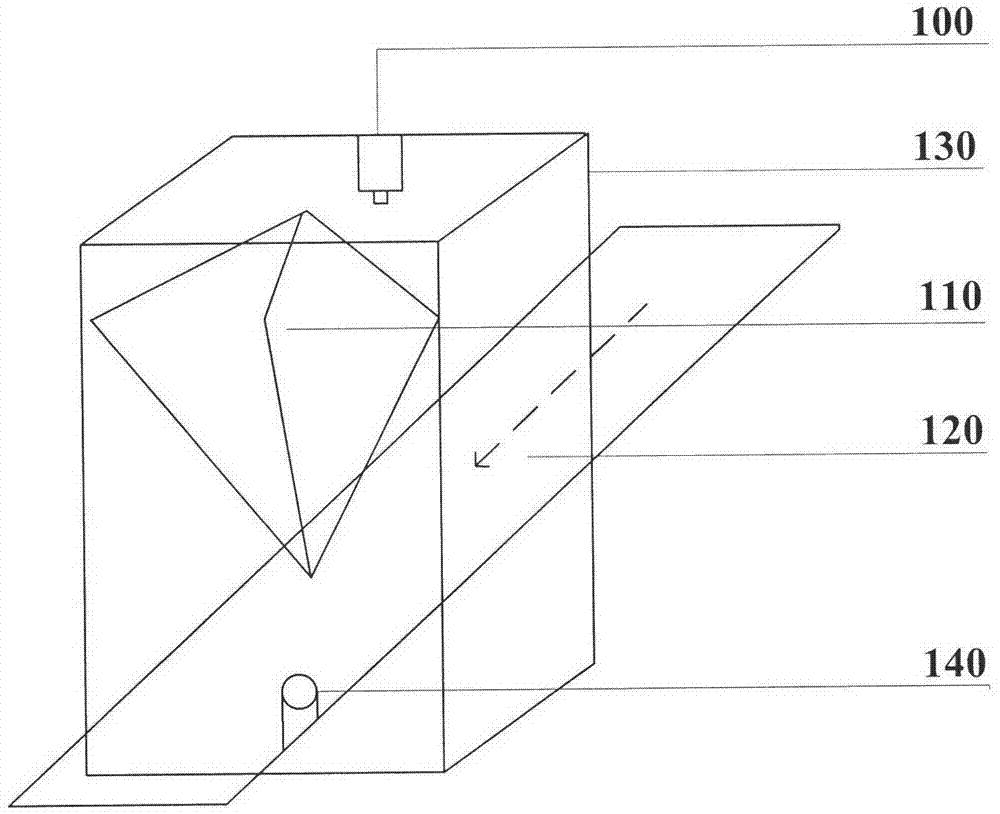

[0040] (1) Install the Delta robot in the three-dimensional steel structure bracket, and establish the camera coordinate system and the robot base coordinate system, and convert the object coordinates recognized by the industrial smart camera to the robot's base coordinate system

[0041](1.1) four-degree-of-freedom Delta robot 110 is installed in the three-dimensional support 130, and the four-degree-of-freedom Delta robot 110 can move in the three-dimensional support 130; The front end of the three-dimensional support 130 adopts a global mode to install the industrial smart camera 100, the three-dimensional support 130 A conveyor belt 120 is arranged inside, and the motion direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com