Three-channel ion-source sprayer nozzle

An ion source and three-channel technology, applied in the direction of ion source/gun, particle separation tube, particle separator tube parts, etc., can solve the problems of low cost, inconvenient use, low stability, etc., and achieve low cost and high use Convenience, easy assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

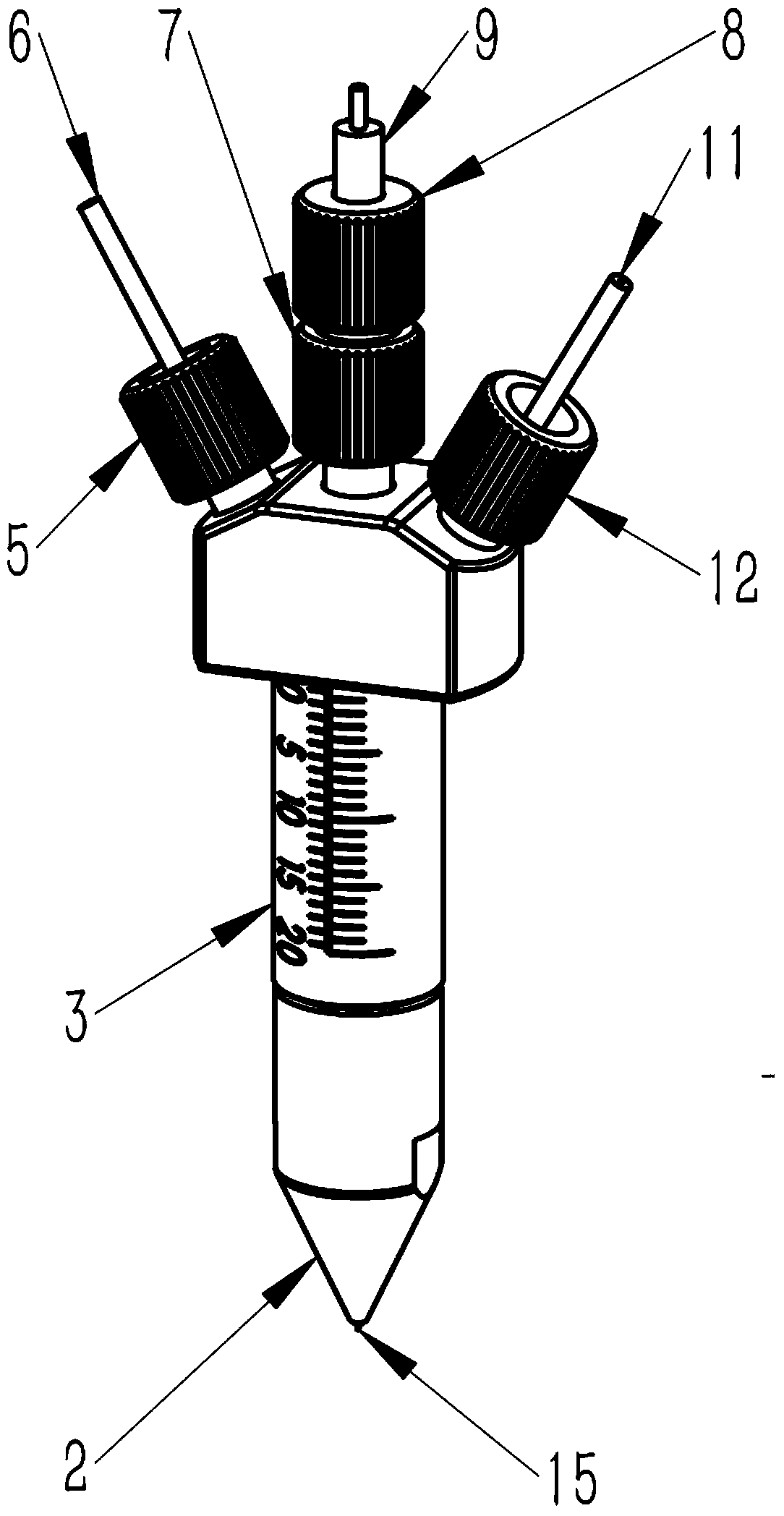

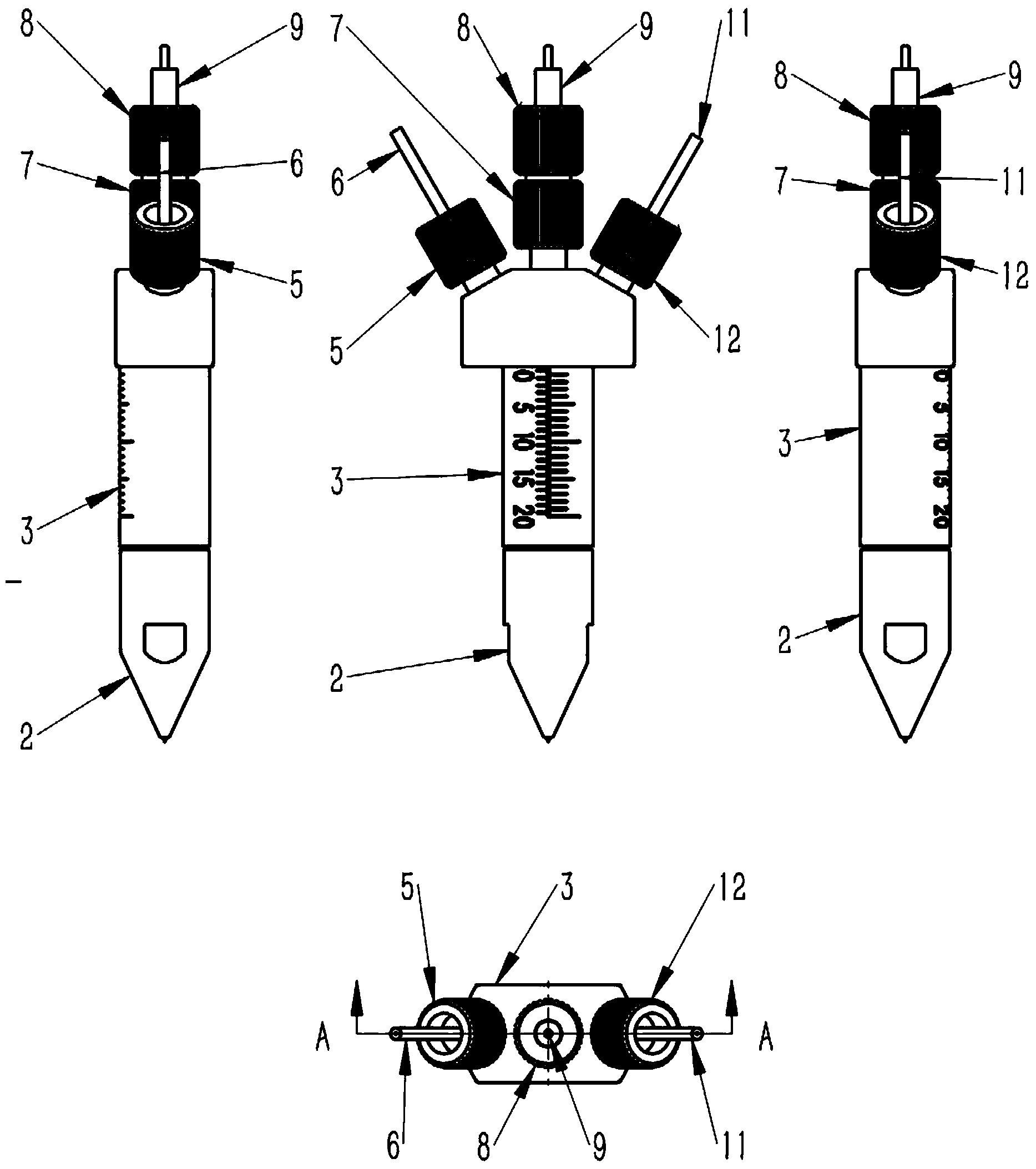

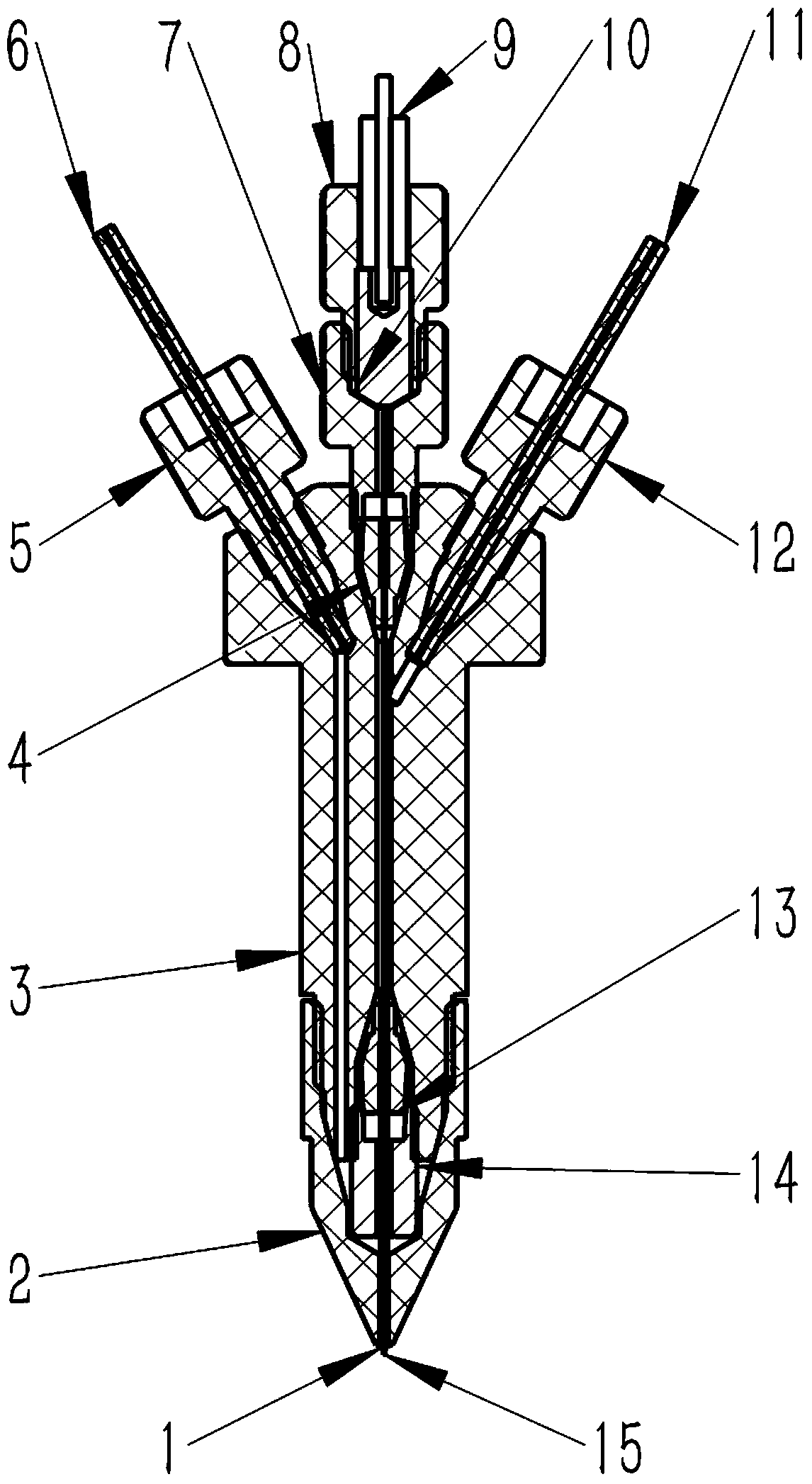

[0048] The specific embodiment of the present invention is illustrated below in conjunction with accompanying drawing, among the figure identical structure and the device of function have been marked with identical reference numeral, accompanying drawing is only used to help explain the present invention, does not represent the limitation of the scope of the present invention, Also, the drawings are not drawn to scale.

[0049] Such as figure 1 , 2As shown, from the appearance, the present invention includes a three-way joint 3 of an ion source nozzle, and the parts for air intake, liquid inlet and high pressure are all arranged at the tail of the three-way joint 3, and on the three-way joint 3, they are mutually angled. There are three hollow screw heads, which are the air intake pipe locking screw 5, the electrode wire locking screw 7 and the liquid inlet pipe locking screw 12, respectively, from the center holes of the three screw heads to the inside of the tee joint 3. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com