Three-dimensional semiconductor memory device based on deep hole filling and preparation method thereof

A semiconductor and memory technology, which is applied in the field of three-dimensional semiconductor memory based on deep hole filling and its preparation, can solve the problems of deep holes being easily covered by deposited materials, uneven deposition of deep holes, and hindering the continued deposition of deep holes, etc. Increased density, high storage density, the effect of increasing storage density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

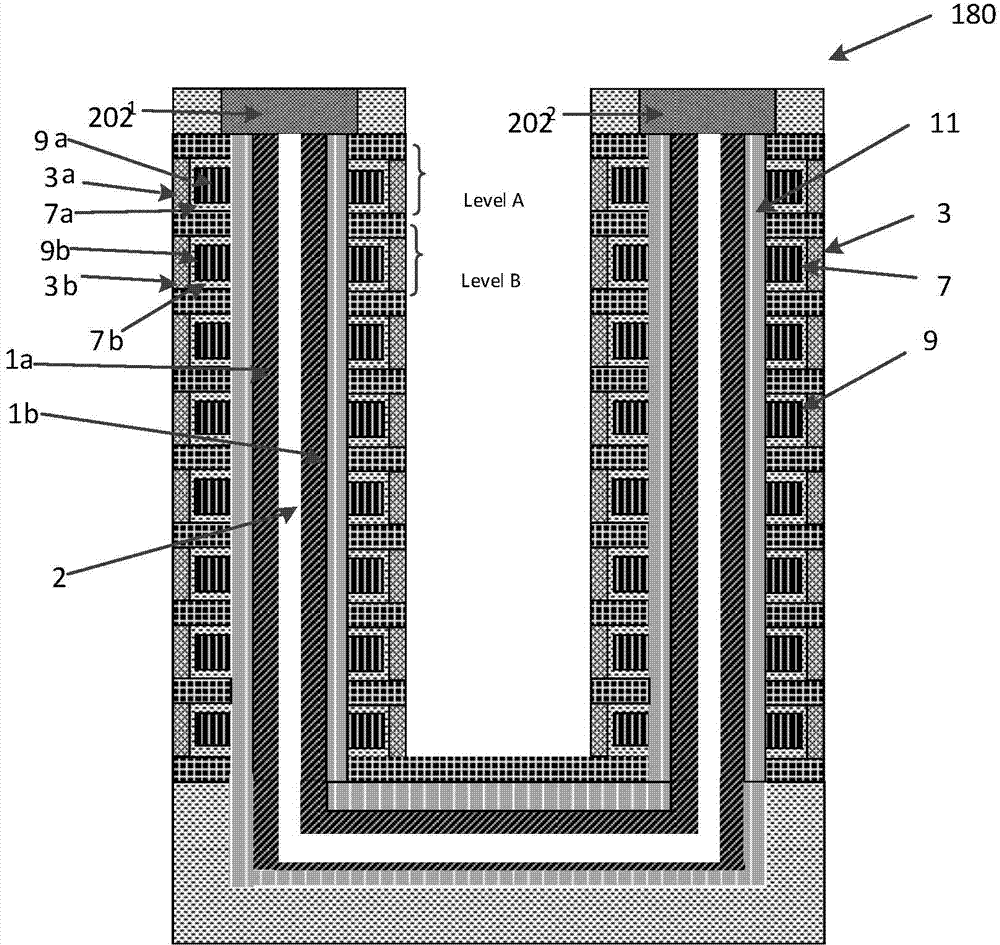

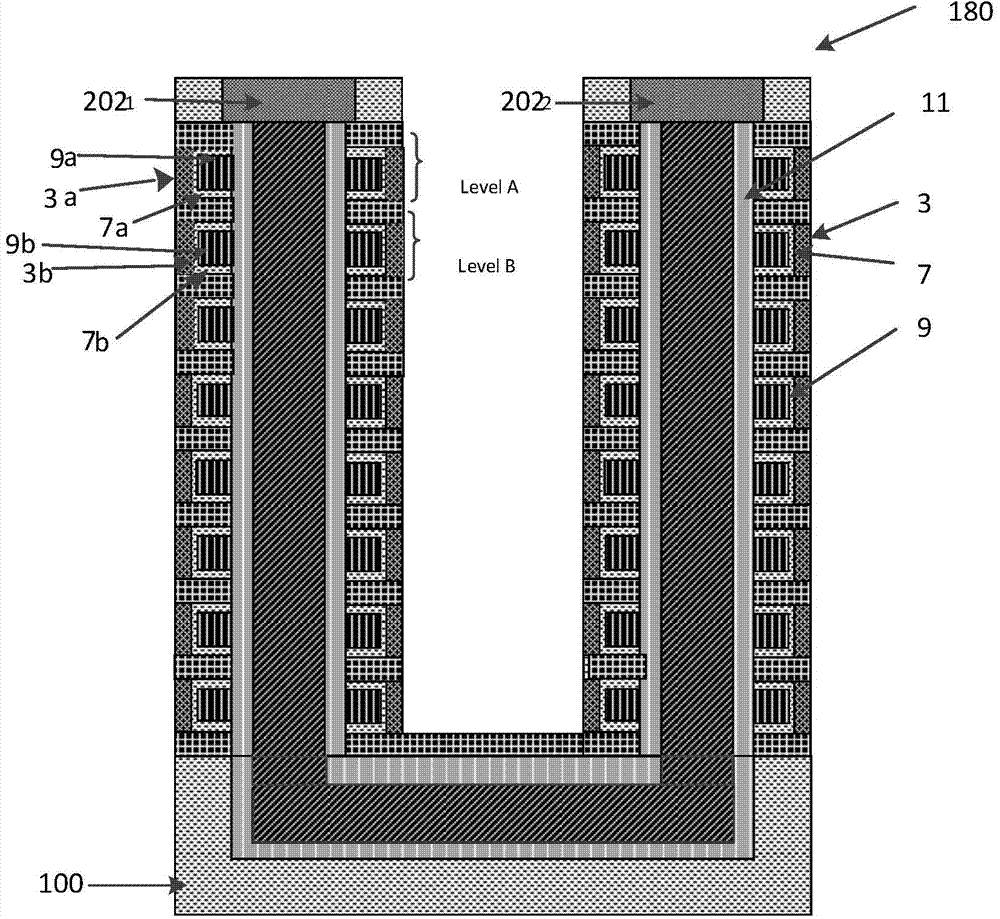

[0033] The source / drain of the NAND string is formed on the semiconductor channel 1 and as figure 1 and 2 As shown, channel 1 is U-shaped. Contact electrode 202 (including 202 1 、202 2 ) provides contact with the semiconductor channel 1 . The shape of the U-shaped tube in this paper is similar to the English letter "U". The electrodes of the U-shaped channel semiconductor storage device are drawn from the top of the device, which reduces the contact area of the electrode; at the same time, the NAND string of the U-shaped semiconductor storage device can include a stacked structure in which at least one semiconductor layer and an insulating layer are alternately stacked, increasing The number of devices per unit area is increased, so the U-shaped channel semiconductor memory can greatly increase the storage density.

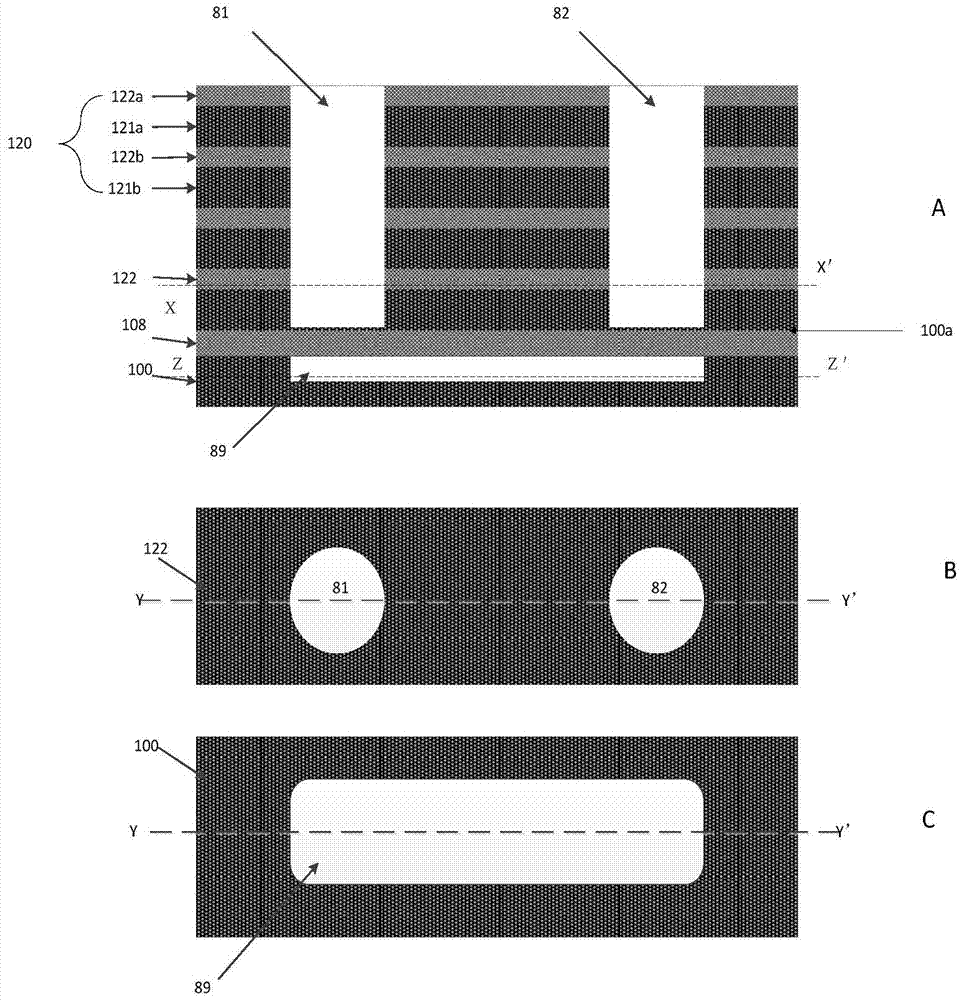

[0034] Combine below Figure 3-14 , specifically describe the process of preparing U-shaped semiconductor channel NAND strings.

[0035] (1) Form a sacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com