Evaporation source for transporting chemical precursors, and evaporation method for transporting chemical precursors using said source

A chemical precursor and evaporation source technology, applied in vacuum evaporation plating, gaseous chemical plating, coating, etc., can solve problems such as blocking delivery pipes, matrix impact, and affecting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

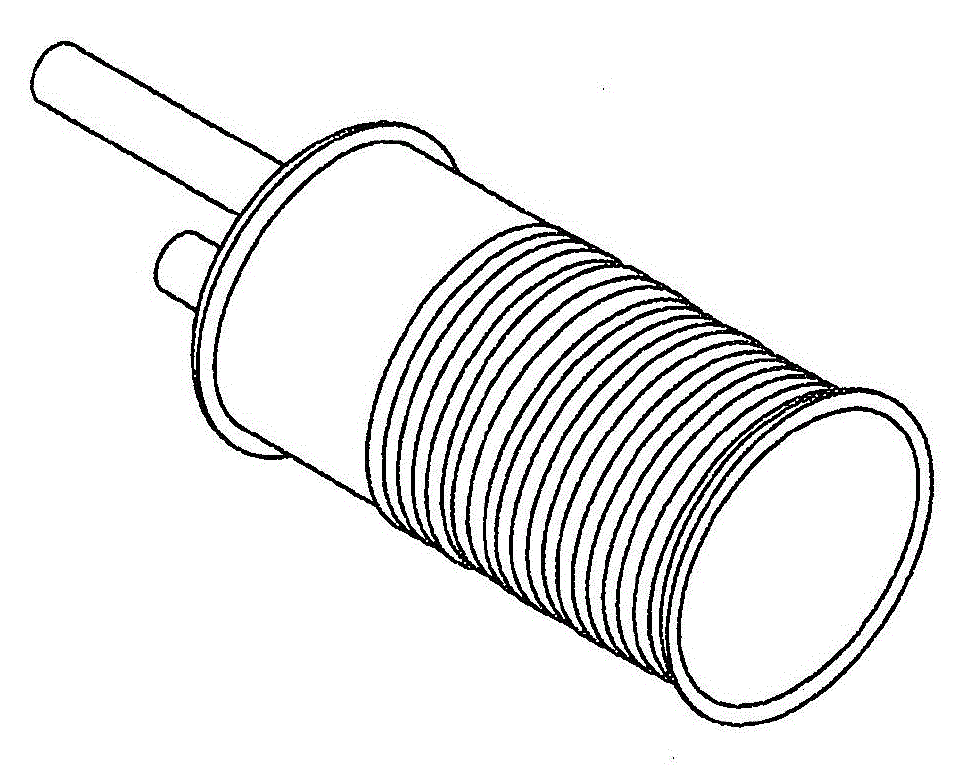

[0049] The object of the present invention is an evaporation source for delivering chemical precursors to a substrate on which the chemical precursors are deposited by condensation.

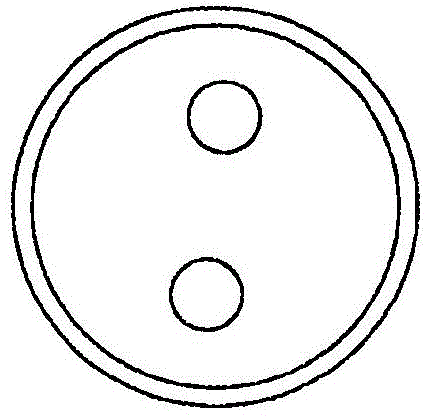

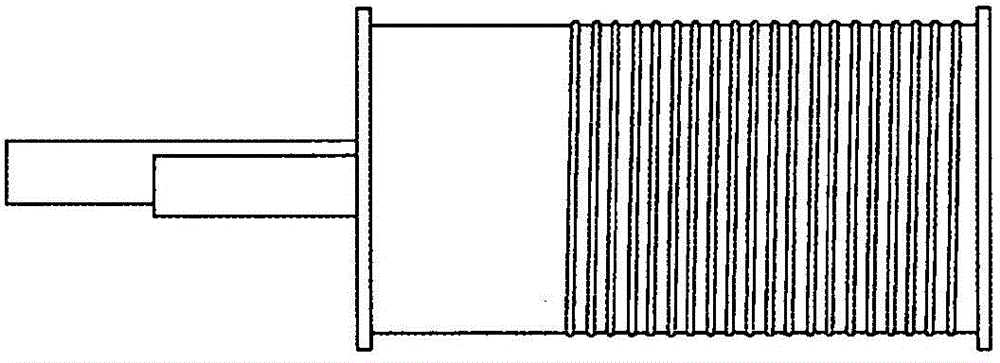

[0050] As can be observed in the figure, the evaporation source that is the object of the invention is formed by a hollow main tube 1 with a lower and upper removable cover 2 to provide access to the interior of the hollow main tube housing the precursors. import and export.

[0051] In particular, the main pipe 1 is made of metallic material, which may be stainless steel, copper, titanium or a combination of said materials. Furthermore, coatings made of alloys such as nickel, vanadium, molybdenum, chromium or alloys of combinations of these elements may be present.

[0052] The main tube is divided into an upper part 4 and a lower part 3 in which the precursor is housed.

[0053] In the upper part 4 there are arranged an inlet 5 through which a carrier gas inlet pipe 9 is connected to the insi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com