Method for forming contact hole with high aspect ratio

A high aspect ratio, contact hole technology, applied in electrical components, transistors, circuits, etc., can solve problems such as reducing production capacity and efficiency, increasing process cycle, etc., to improve performance, increase conduction speed, and reduce RC resistance The effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the method for forming a high aspect ratio contact hole provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

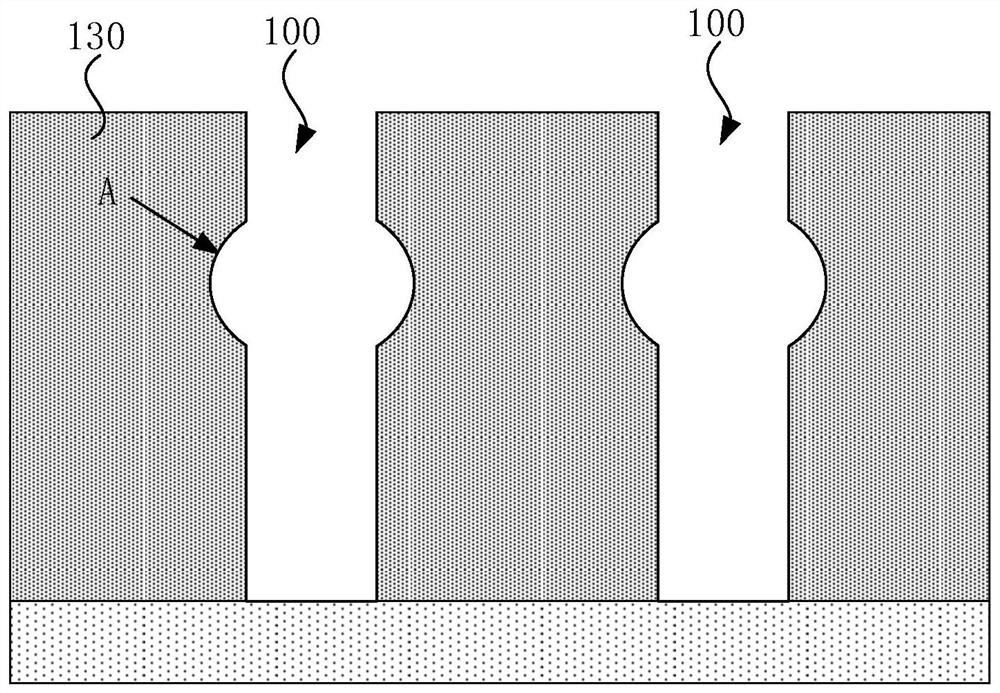

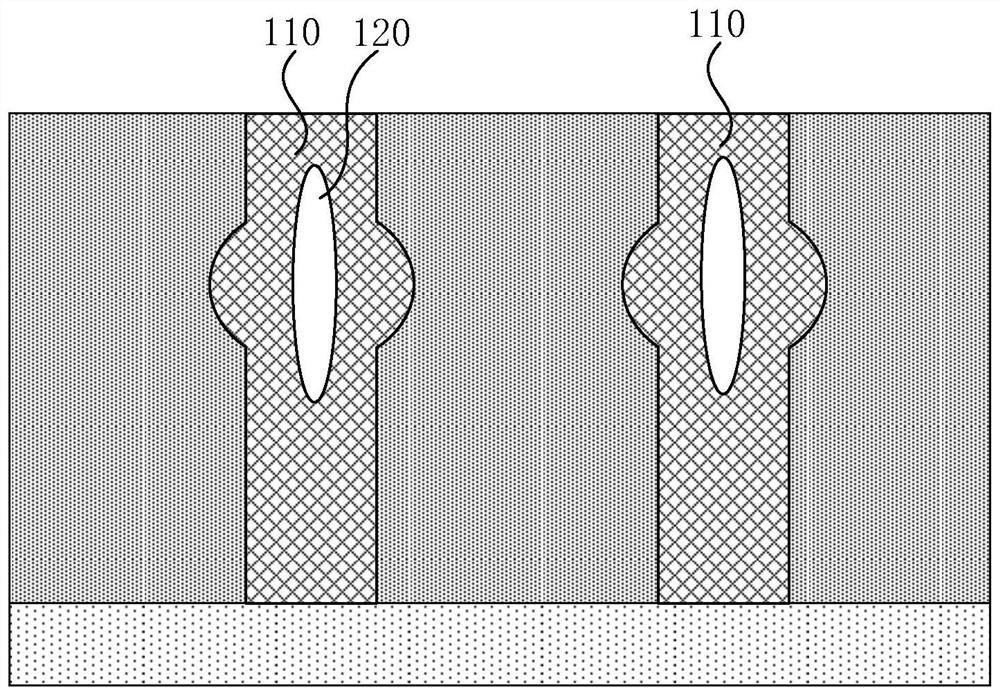

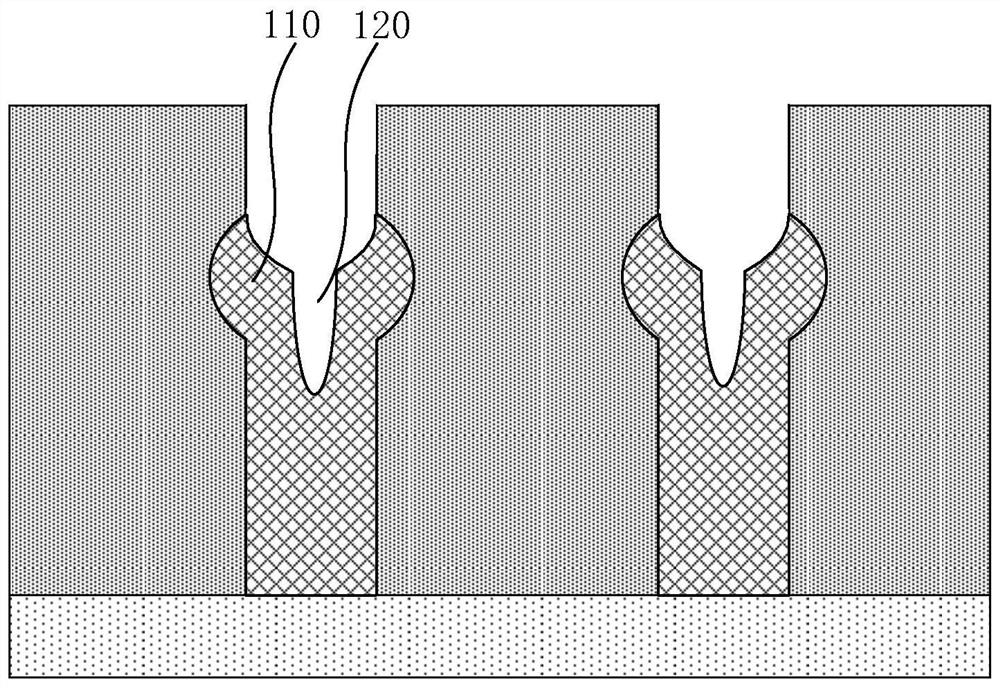

[0027] figure 2 is a schematic diagram of the steps of a specific embodiment of the method for forming a high aspect ratio contact hole of the present invention, please refer to figure 2 The method for forming a contact hole with a high aspect ratio of the present invention comprises the following steps: step S20, providing a substrate; step S21, forming a dielectric layer on the substrate, the dielectric layer including a non-over-etching region and an easy-over-etching region. etching area, and the dielectric layer includes at least two sub-dielectric layers and an auxiliary layer located between the sub-dielectric layers, the auxiliary layer is located in the easily overetched area, and the sub-dielectric layer is located in the In the non-overetched region, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com