Double-disc-serial-connecting pump light multi-pass transmission system and disc solid laser

A transmission system and pump light technology, applied in the laser field, can solve the problems of affecting the conversion rate of the system, limiting the quality of the output laser, and surface distortion, etc., and achieve the effects of improving utilization, reducing costs, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

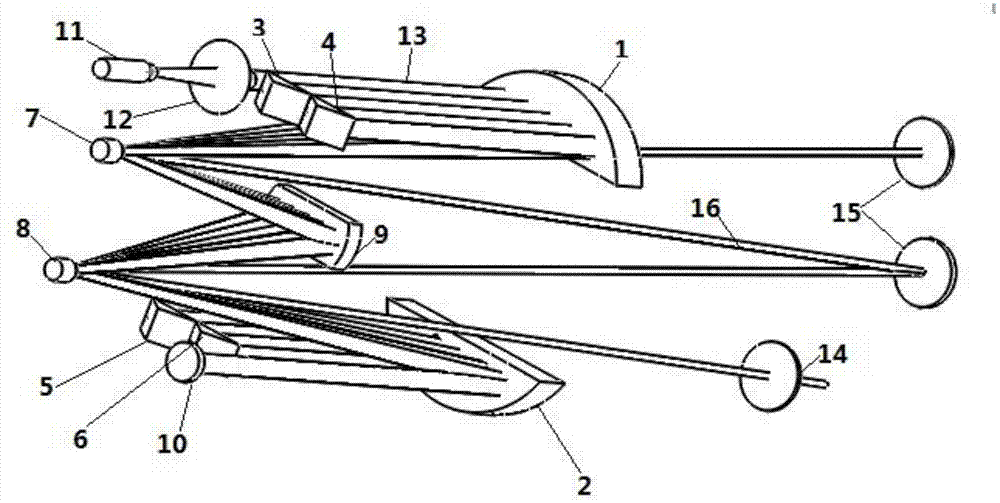

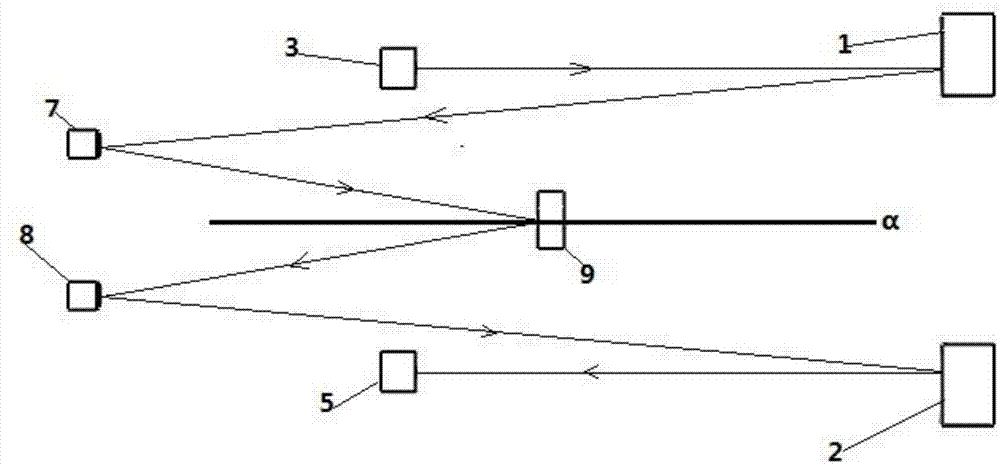

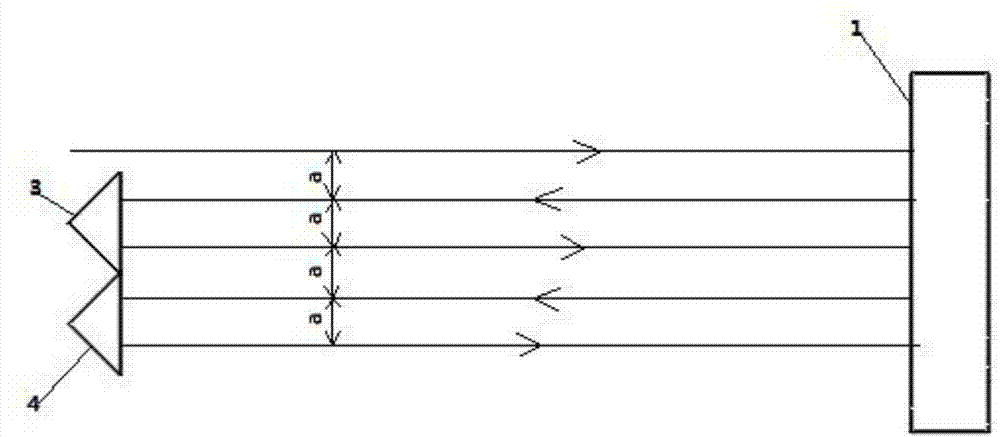

[0046] Such as figure 1 As shown, the first off-axis parabolic reflector 1, the first disc laser crystal 7, the second off-axis parabolic reflector 2, and the second disc laser crystal 8 are arranged symmetrically about the same plane α, and the plane α passes through the spherical reflector 9 and the spherical mirror is divided into two parts with the same shape and symmetrical position, that is, the symmetrical surface of the spherical mirror. The first disc laser crystal 7 is located at the focal point of the first off-axis parabolic mirror 1, and the second disc laser crystal 8 is located at the focal point of the second off-axis parabolic mirror 2. The first disc laser crystal 7 and the second disc laser crystal 8. The normal of the reflective surface, the optical axes of the first off-axis parabolic reflector 1, the second off-axis parabolic reflector 2, and the optical axis of the spherical reflector 9 are parallel to each other. The first right-angle reflector group i...

Embodiment 2

[0051] Pump light multi-pass transmission system, such as Figure 5As shown, the first off-axis parabolic reflector 1, the first disc laser crystal 7, the second off-axis parabolic reflector 2, and the second disc laser crystal 8 are arranged symmetrically about the same plane α, and the plane α passes through the spherical reflection The spherical center of the mirror 9 and the spherical mirror are divided into two parts of the same shape and position symmetry, i.e. the symmetrical surface of the spherical mirror. The first disc laser crystal 7 is located at the focus of the first off-axis parabolic mirror 1, the second disc laser crystal 8 is located at the focus of the second off-axis parabolic mirror 2, and the first and second disc laser crystals 7 and 8 reflective surfaces The normal line of is parallel to the optical axes of the first and second off-axis parabolic reflectors and spherical reflectors. The first rectangular reflector group only comprises the first rectan...

Embodiment 3

[0057] Such as Figure 9 As shown, the first off-axis parabolic reflector 1, the first disc laser crystal 7, the second parabolic reflector 2, and the second disc laser crystal 8 are arranged symmetrically about the same plane α, and the plane α passes through the ellipsoidal reflector 17 The center of the sphere and the ellipsoid mirror is divided into two parts with the same shape and position symmetry, that is, the symmetrical surface of the ellipsoid mirror. The first disc laser crystal 7 is located at the focal point of the first off-axis parabolic mirror 1, and is also located at one of the focal points of the ellipsoidal reflector, and the second disc laser crystal 8 is located at the focal point of the second off-axis parabolic mirror 2, and is also at the same time Another focal point of the ellipsoid reflector, the normal of the first disc laser crystal 7 and the reflective surface of the second disc laser crystal 8, the first off-axis parabolic reflector 1, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com