Method for detecting sulphur poisoning in an exhaust treatment system

A technology for exhaust gas post-treatment and exhaust gas flow, which is applied in the electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, and exhaust gas treatment, etc. It can solve the problem of no indication of sulfur poisoning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

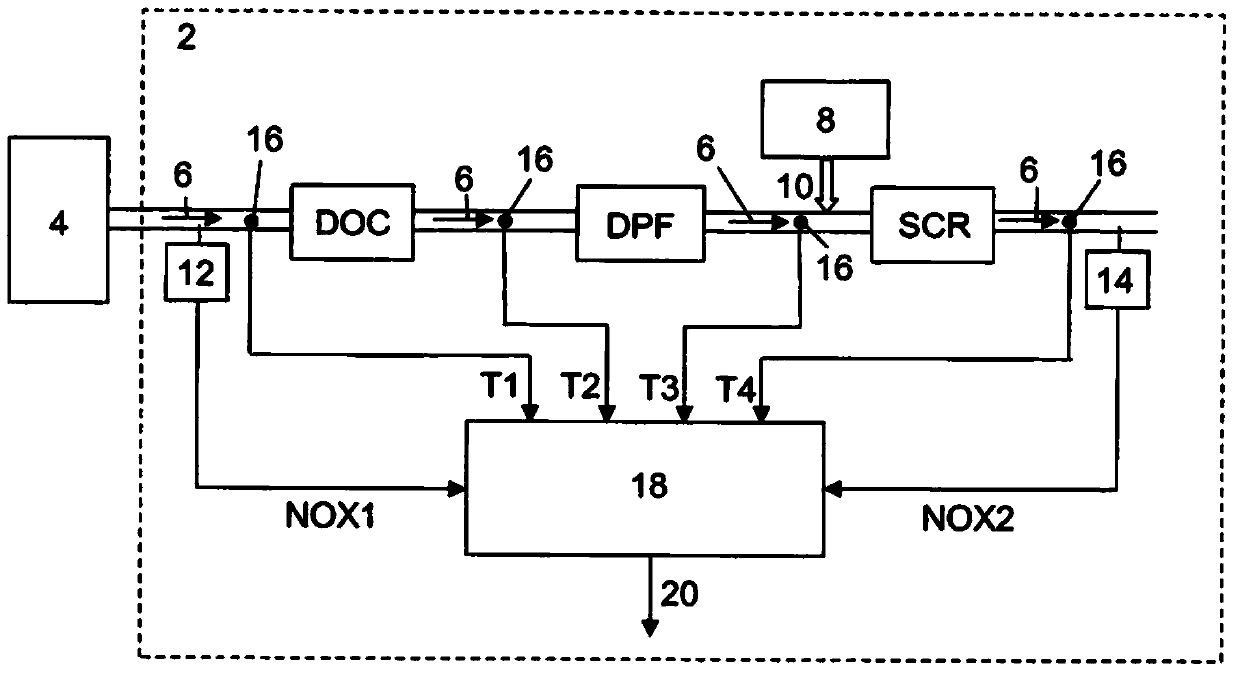

[0034] figure 1 is a schematic diagram of the exhaust gas aftertreatment system according to the present invention.

[0035] figure 1 An exhaust gas aftertreatment system 2 for a combustion engine 4 which generates an exhaust gas flow 6 is depicted. System 2 includes a system designed to convert NO into NO 2 at least one diesel oxidation catalyst (DOC) and at least one selective catalytic reduction catalyst (SCR catalyst). A Diesel Particulate Filter (DPF) is also preferably located downstream of the DOC. This filter can be uncoated or provided with a catalytic coating. Here soot and ash are collected and NO to NO 2 A certain degree of transformation also takes place here.

[0036] The system also comprises a reductant device 8 adapted to supply a reductant 10 such as urea or ammonia to the exhaust gas flow 6 upstream of the SCR catalyst, NO and NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com