Protection device for carrying out girth welding on nuclear class equipment cylinder and girth welding technology

A protective device and girth welding technology, applied in the direction of providing/removing protective gas devices, welding equipment, welding accessories, etc., can solve the problems of high cost, difficult operation, limited use, etc., and achieve good quality and fast welding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

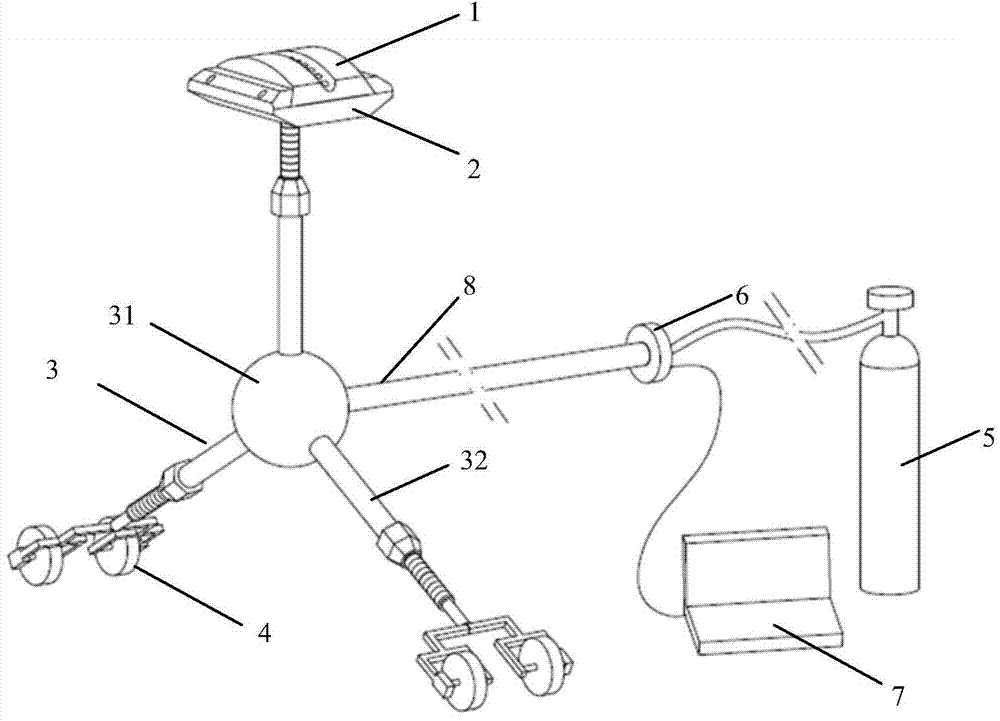

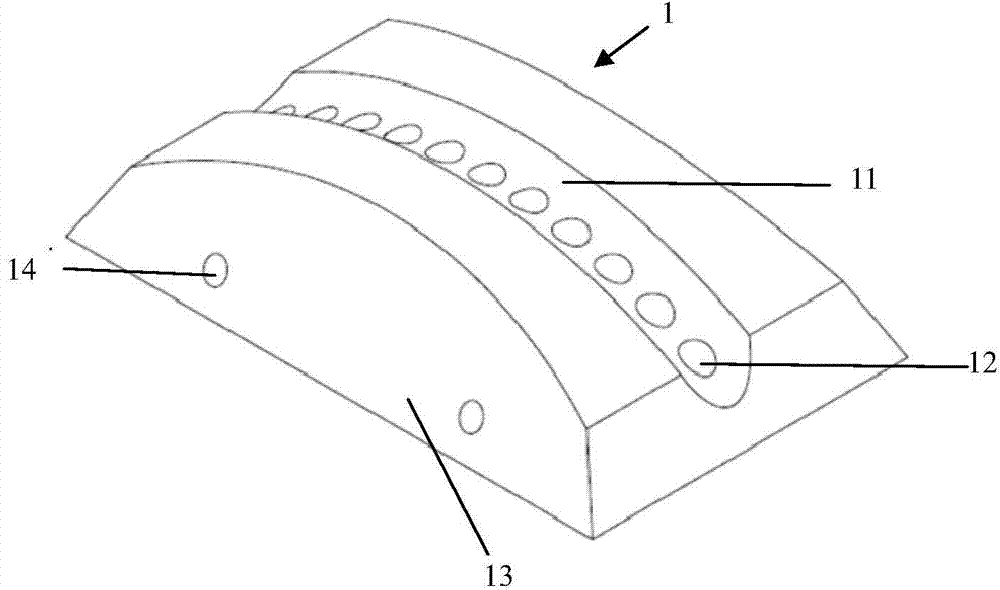

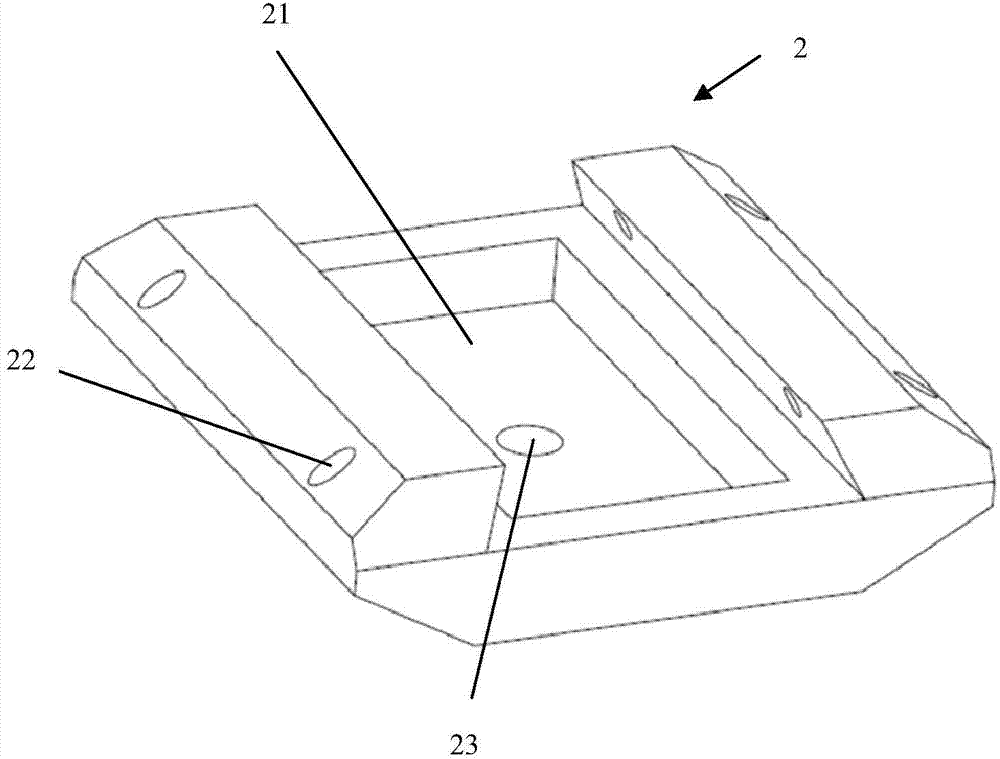

[0035] Such as figure 1 As shown, the nuclear-level equipment cylinder circular seam welding protection device of the present invention consists of a detachable lining block 1, a supporting block 2, an adjustable outrigger mechanism 3, a protective gas supply device 5, a traveling mechanism 4, a speed regulator 6 and The control computer consists of 7 components. The detachable lining block 1 is arranged on the support block 2, and the adjustable outrigger mechanism 3 is provided under the support block 2, and the adjustable outrigger mechanism 3 is connected to the protective gas supply device 5 through the insertion rod (8); Both the adjustable outrigger mechanism 3 and the insertion rod 8 are provided with a protective gas channel, and the protective gas channel communicates with the protective gas supply device 5 and the gas collection groove 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com