Supercritical fluid conveying device

A supercritical fluid and delivery device technology, applied in the direction of gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve problems such as complex structure design, control lag, and influence on experimental technology, so as to improve work efficiency and stabilize transportation Effects with precise control and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

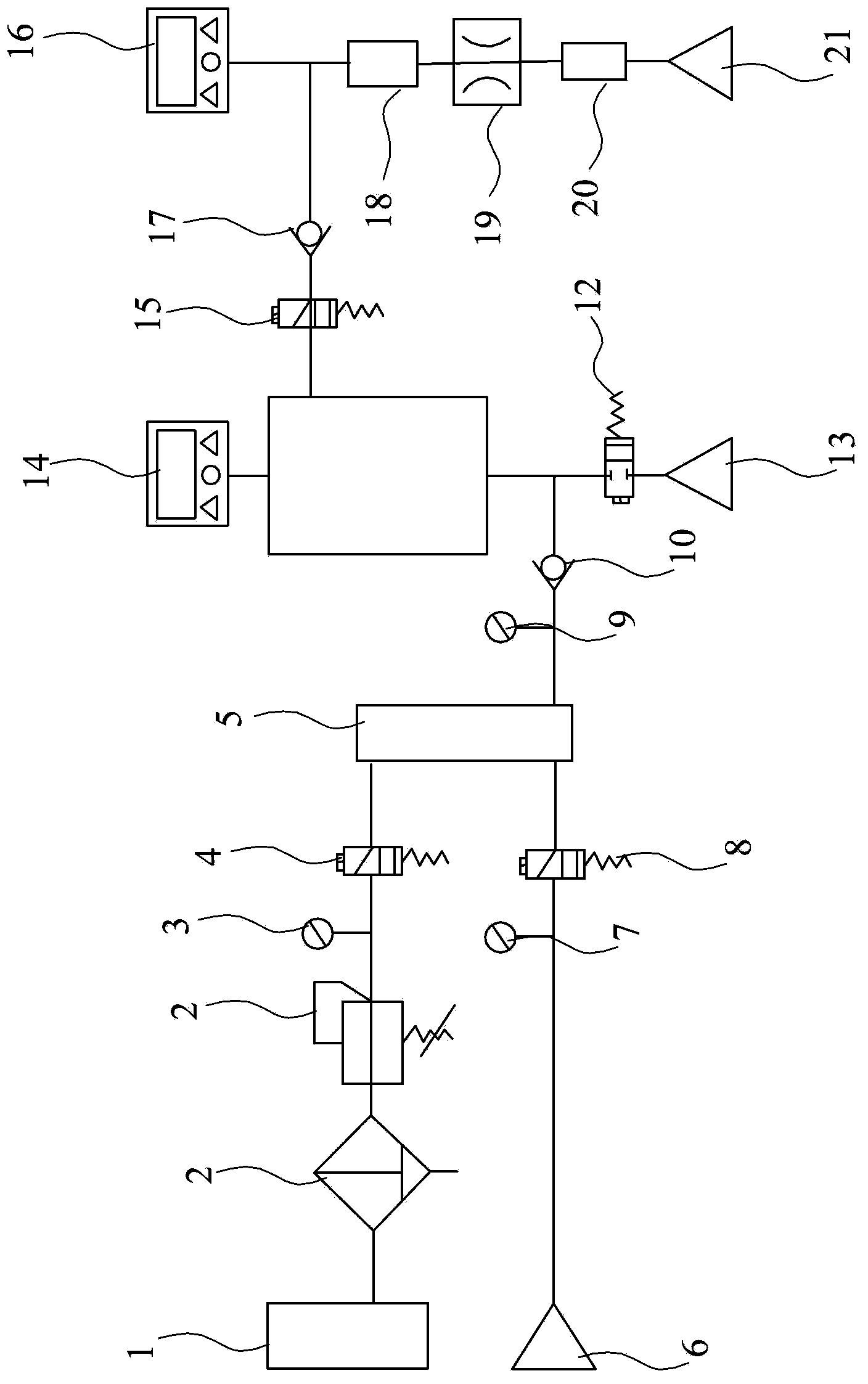

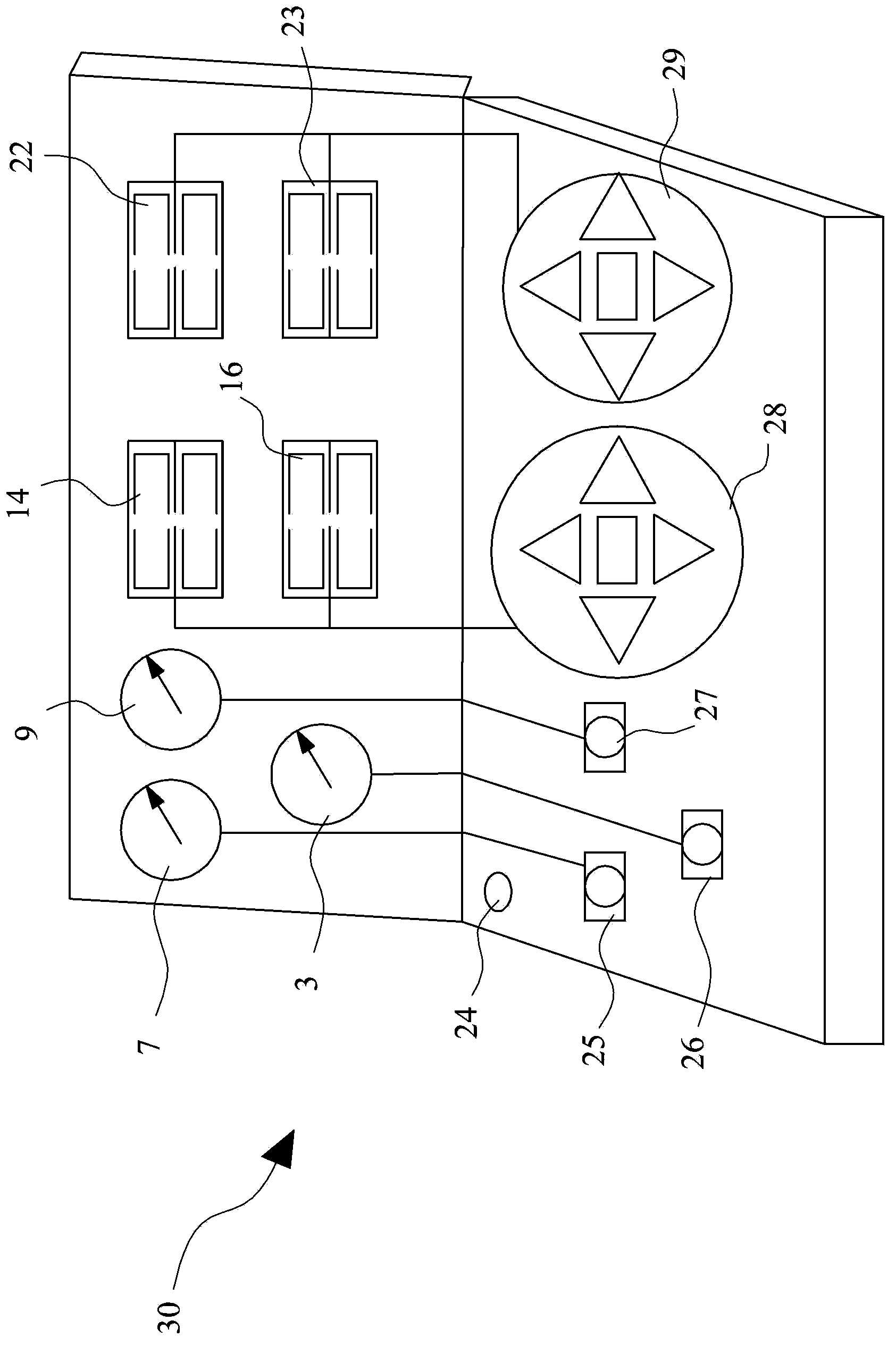

[0024] figure 1 and figure 2 The supercritical fluid delivery device of this embodiment includes a gas source control device, a pressurization control device, a storage device and an electric control device. The air source control device is composed of an air source 6, an intake pressure gauge 7 and an intake air on-off solenoid valve 8, wherein the intake air pressure gauge 7 is located between the air source 6 and the intake air on-off solenoid valve 8, and the air source 6 is carbon dioxide Or a blend of nitrogen or carbon dioxide and nitrogen in any proportion. The supercharging control device is connected in sequence by a low-noise air compressor 1, a filter decompression air source triple unit 2, an air pressure gauge 3, an on-off solenoid valve 4, a booster pump 5, a high-pressure pressure gauge 9 and a first check valve 10 At the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com