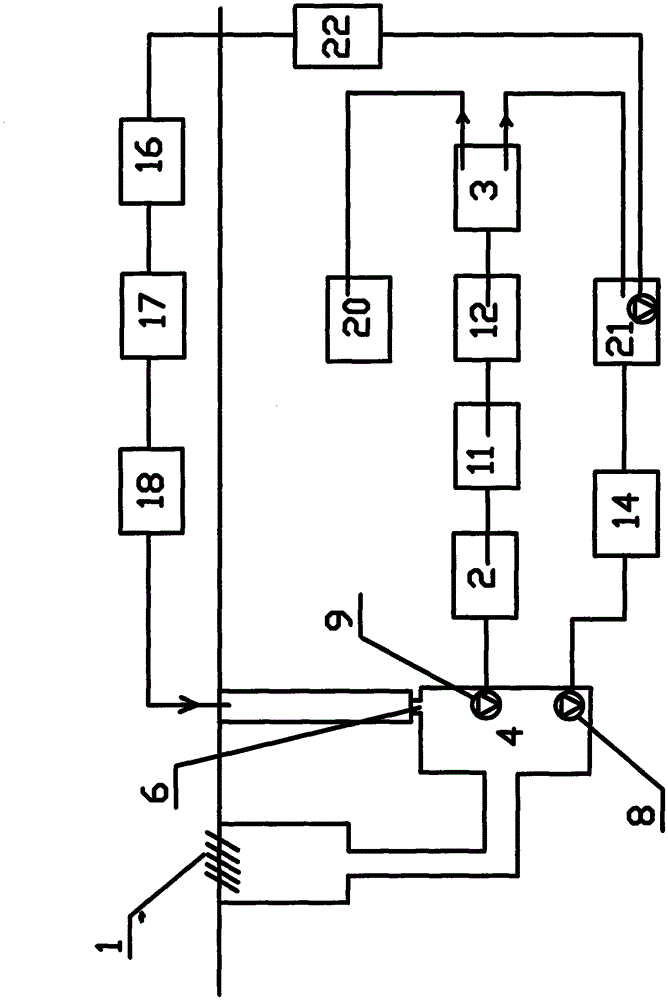

An underground sewage treatment device

A sewage treatment device and sewage technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of not getting proper treatment and poor sewage treatment effect, and achieve Effect of reducing processing pressure and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

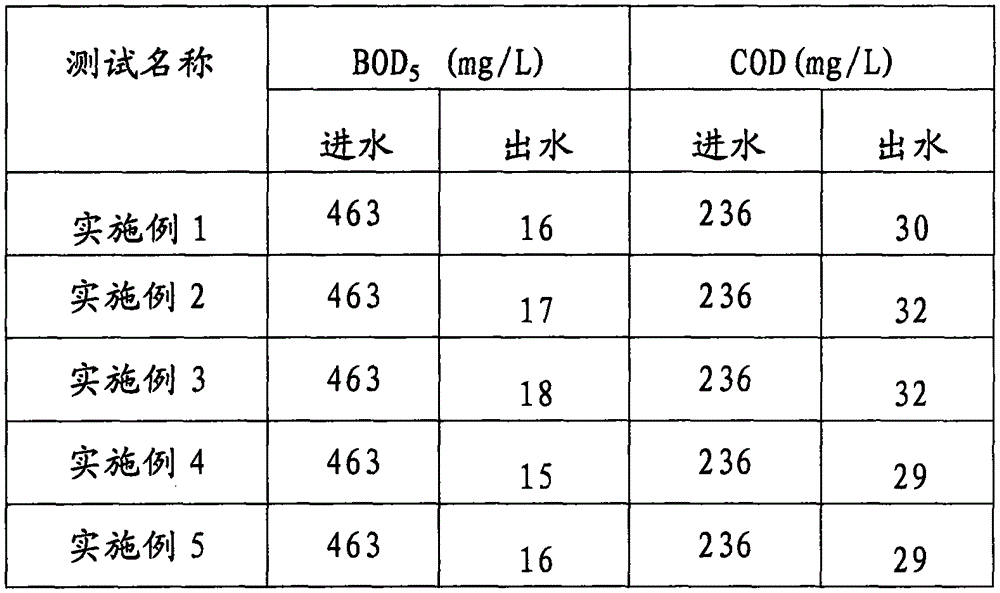

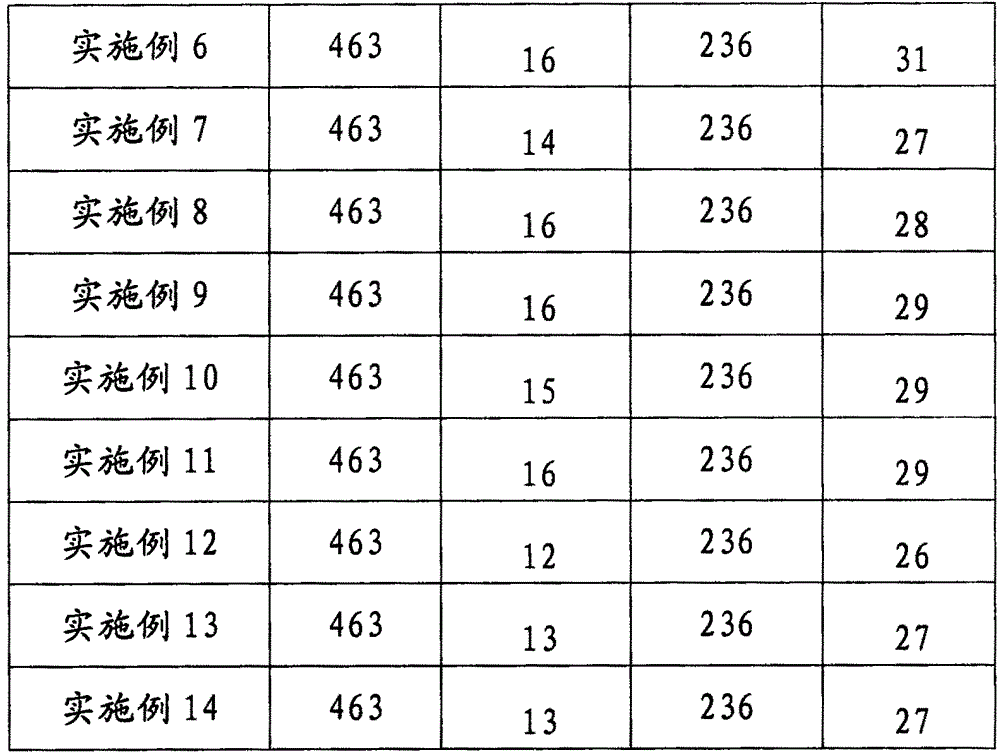

Embodiment 1

[0048] (1) Sewage enters the activation pool 4 through the grille 1, and the stirring device is turned on to stir the sludge. During stirring, forward stirring and reverse stirring are alternately carried out, and the stirring time is 1 hour. The stirring time is equal to 0.5h respectively;

[0049] After stirring, let it stand for 1.5 hours, then add surfactant to the sewage in the activation pool 4, and simultaneously turn on the two counter-rotating stirring devices to shear and mix the sewage and surfactant, and after mixing evenly, let it stand for 3 hours Stratification, discharge the upper layer liquid to the anaerobic tank 2, and pump the lower layer of sludge to the sludge tank 21;

[0050] In the present embodiment, selecting described tensio-active agent to be sodium dodecylbenzene sulfonate, the mass ratio of sodium dodecylbenzenesulfonate and described sewage is 1: 8;

[0051] (2) Sewage is anaerobically treated in the anaerobic pool 2 for 5 hours, and the sewage...

Embodiment 2

[0054] (1) The sewage enters the activation pool 4 through the grid 1, and the stirring device is turned on to stir the sludge. During stirring, forward stirring and reverse stirring are alternately carried out, and the stirring time is 3 hours. The stirring time is equal to 1.5h respectively;

[0055] After stirring, let it stand for 3 hours, then add a surfactant to the sewage in the activation pool 4, and simultaneously turn on two counter-rotating stirring devices to shear and mix the sewage and the surfactant. layer, discharge the upper liquid to the anaerobic tank 2, and pump the sludge from the lower layer to the sludge tank 21;

[0056] In the present embodiment, select described tensio-active agent to be sodium dodecylbenzene sulfonate, the mass ratio of sodium dodecylbenzenesulfonate and described sewage is 1: 9;

[0057] (2) Sewage is subjected to anaerobic treatment in the anaerobic pool 2 for 3 hours, and the sewage after the anaerobic treatment enters the anoxic...

Embodiment 3

[0060] (1) Sewage enters the activation pool 4 through the grid 1, and the stirring device is turned on to stir the sludge. During stirring, forward stirring and reverse stirring are alternately carried out, and the stirring time is 5 hours. The stirring time is equal to 2.5h respectively;

[0061] After stirring, let it stand for 3 hours, then add a surfactant to the sewage in the activation pool 4, and simultaneously turn on two counter-rotating stirring devices to shear and mix the sewage and the surfactant. layer, discharge the upper liquid to the anaerobic tank 2, and pump the sludge from the lower layer to the sludge tank 21;

[0062] In the present embodiment, selecting described tensio-active agent to be sodium dodecylbenzenesulfonate, the mass ratio of sodium dodecylbenzenesulfonate and described sewage is 1: 10;

[0063] (2) Sewage is anaerobically treated in the anaerobic pool 2 for 8 hours, and the sewage after the anaerobic treatment enters the anoxic pool 11 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com