Low-temperature setting polyester resin

A polyester resin, low-temperature technology, applied in the field of low-temperature curing polyester resin, can solve the problems of insufficient leveling, high reactivity, and insufficient reactivity, etc., achieve good leveling and chemical resistance, good storage stability, and improve The effect of reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

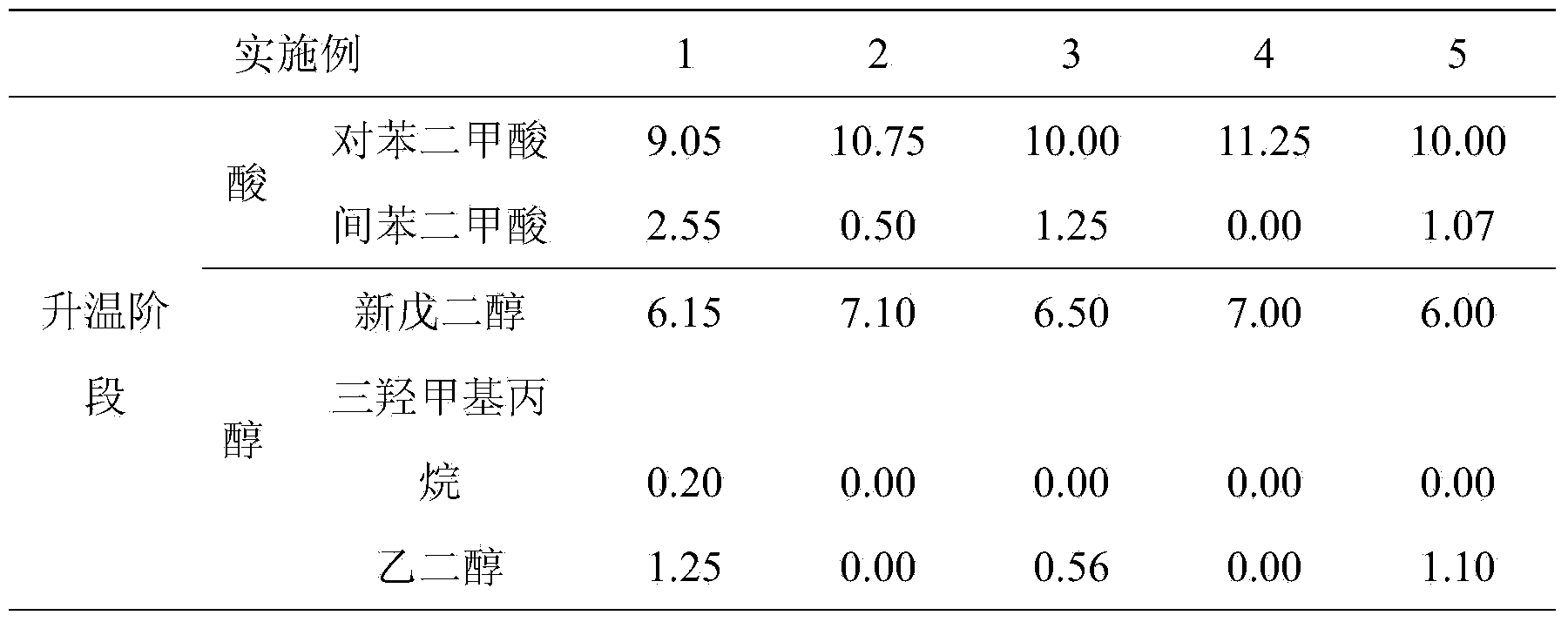

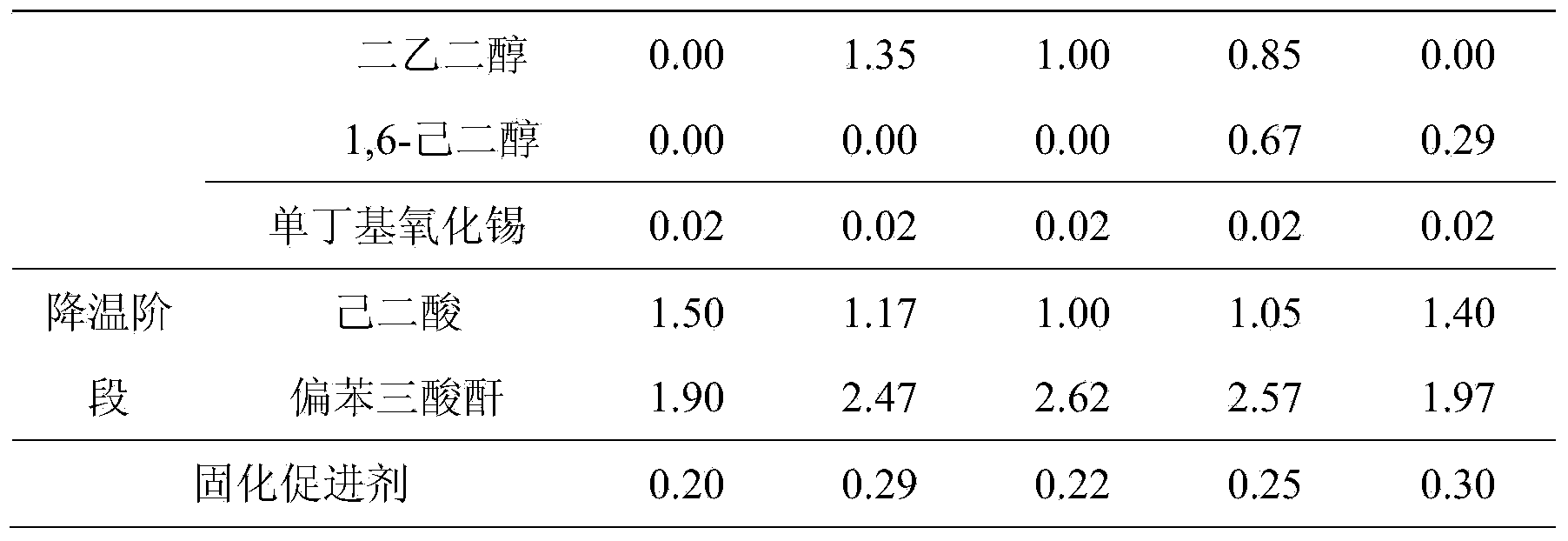

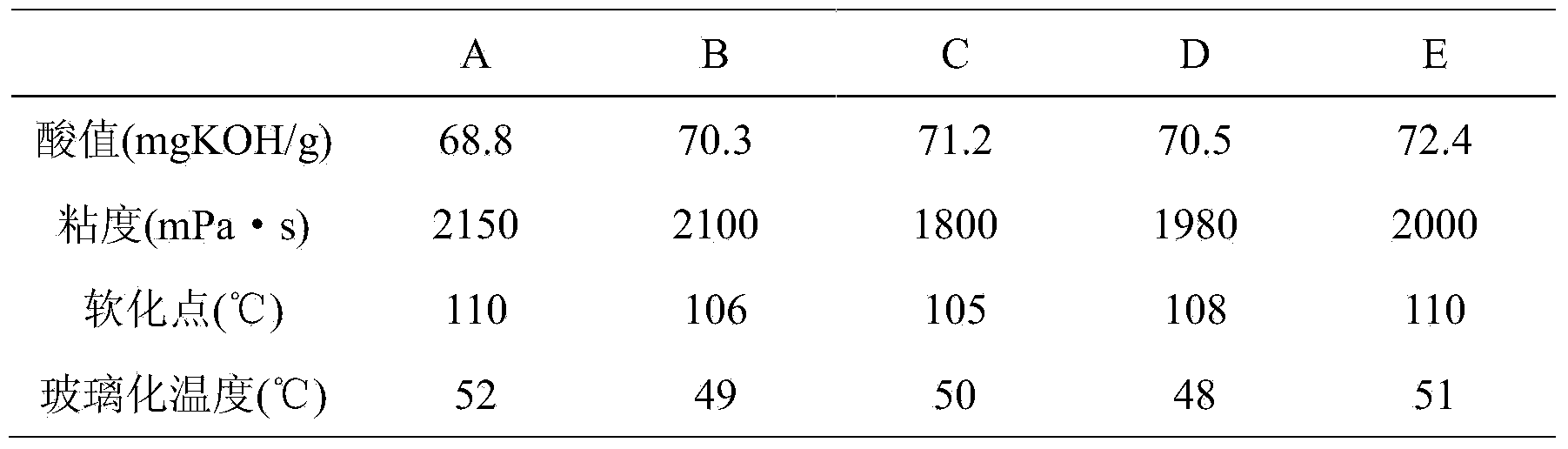

[0021] A low-temperature curing polyester resin, its raw material components and their quality are shown in Table 1.

[0022] Preparation of polyester resin:

[0023] (1) Heating stage: raise the temperature of the reaction kettle to 110°C, start stirring, and put in the formulated amount of alcohol, acid, and formulated amount of esterification catalyst in sequence. Raise the temperature to 215°C at a heating rate of 2°C / 15min, and finally raise the temperature to 247°C at a heating rate of 2°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect an acid value of 9.3mgKOH / g;

[0024] (2) Cooling stage: lower the temperature of the kettle to 185°C, put in acid, and then raise the temperature to 220°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect an acid value of 83.4mgKOH / g;

[0025] (3) Vacuum stage: At 210°C, vacuumize for 3 hours at a vacuum degree o...

Embodiment 2

[0028] A low-temperature curing polyester resin, its raw material components and their quality are shown in Table 1.

[0029] Preparation of polyester resin:

[0030] (1) Heating stage: raise the temperature of the reaction kettle to 98°C, start stirring, and put in the formulated amount of alcohol, acid, and formulated amount of esterification catalyst in sequence, seal the kettle and raise the temperature to 179°C, Raise the temperature to 210°C at a heating rate of 1°C / 15min, and finally raise the temperature to 248°C at a heating rate of 1°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect an acid value of 7.9mgKOH / g;

[0031] (2) Cooling stage: lower the temperature of the kettle to 190°C, put in acid, and then raise the temperature to 230°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect an acid value of 82.6mgKOH / g;

[0032] (3) Vacuum stage: U...

Embodiment 3

[0035] A low-temperature curing polyester resin, its raw material components and their quality are shown in Table 1.

[0036] Preparation of polyester resin:

[0037] (1) Heating stage: raise the temperature of the reaction kettle to 105°C, start stirring, and put in the formulated amount of alcohol, acid and the formulated amount of esterification catalyst in sequence. Raise the temperature to 220°C at a heating rate of 3°C / 15min, and finally raise the temperature to 246°C at a heating rate of 3°C / 15min, maintain the reaction until the top temperature of the reactor drops below 70°C, and take a sample to detect the acid value of 7.5mgKOH / g;

[0038] (2) Cooling stage: lower the temperature of the kettle to 180°C, put in acid, and then raise the temperature to 225°C for maintenance. After the top temperature of the reaction kettle drops below 60°C, take a sample to detect the acid value of 83.1mgKOH / g;

[0039] (3) Vacuum stage: Under the condition of 205°C, vacuumize for 3.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com