Method for preparing anoectochilus formosanus vinegar through liquid fermentation

A technology of liquid fermentation and fermented vinegar, which is applied in the field of food processing, can solve the undeveloped problems in the field of clematis vinegar production, and achieve the effects of environmental protection, waste utilization, and improvement of nutrition and value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Preparation of fermented vinegar from sugarcane processing residues

[0023] ①Weigh 800g of cleaned sugarcane bagasse and 200g of sugarcane leaves, place them in a pulverizer for primary crushing, the crushed particle size is less than 0.2 cm, and then mix with 3L of water;

[0024] ②In the self-priming fermenter, add 200g of compound enzyme to the mixture obtained in step ①. The compound enzyme is cellulase and hemicellulase with a mass ratio of 1:0.5. Ferment for 10 hours under the condition of 0.2 to obtain liquefied mash;

[0025] ③In a self-priming fermenter, add 40g of glucoamylase to the liquefied mash obtained in step ②, and ferment for 5 hours at 60°C and pH4.2±0.2 to obtain saccharified mash;

[0026] ④In a self-priming fermenter, add 40g of active dry yeast to the saccharified mash obtained in step ③ to carry out alcoholic fermentation, and ferment for 5 days under the conditions of 35°C and pH3.8±0.2 to obtain the saccharified mash;

[0027] ⑤In the sel...

Embodiment 2

[0034] 1) Preparation of fermented vinegar from sugarcane processing residues

[0035] ①Weigh 900g of cleaned sugarcane bagasse and 100g of sugarcane leaves, place them in a pulverizer for primary crushing, the crushed particle size is less than 0.3 cm, and then mix with 3L mountain spring water;

[0036] ②In the self-priming fermenter, add 100g of compound enzyme to the mixture obtained in step ①. The compound enzyme is cellulase and hemicellulase with a mass ratio of 1:0.2. Ferment for 8 hours under the condition of 0.2 to obtain liquefied mash;

[0037] ③In a self-priming fermenter, add 20g of glucoamylase to the liquefied mash obtained in step ②, and ferment for 8 hours at 65°C and pH4.2±0.2 to obtain saccharified mash;

[0038] ④In a self-priming fermenter, add 30g of active dry yeast to the final saccharified mash obtained in step ③ for alcoholic fermentation, and ferment for 3 days at 37°C and pH 3.8±0.2 to obtain the saccharified mash;

[0039] 5. In the self-priming...

Embodiment 1-2

[0047] Table 1: Sensory Test of Clematis Vinegar Example 1-2

[0048]

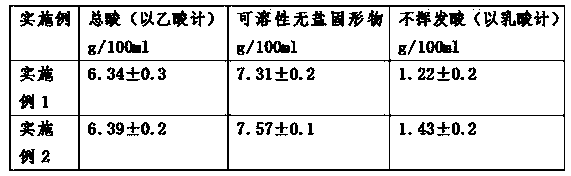

[0049] Table 2: Physicochemical tests of clematis vinegar embodiment 1-2

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com